Gas-driven actuator hysteresis modeling method, system and medium based on Gaussian model

A technology of hysteresis modeling and Gaussian model, which is applied in the field of hysteresis modeling, can solve problems affecting identification accuracy and identification efficiency, and achieve the effects of less model parameters, easy inversion, improved grinding quality and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

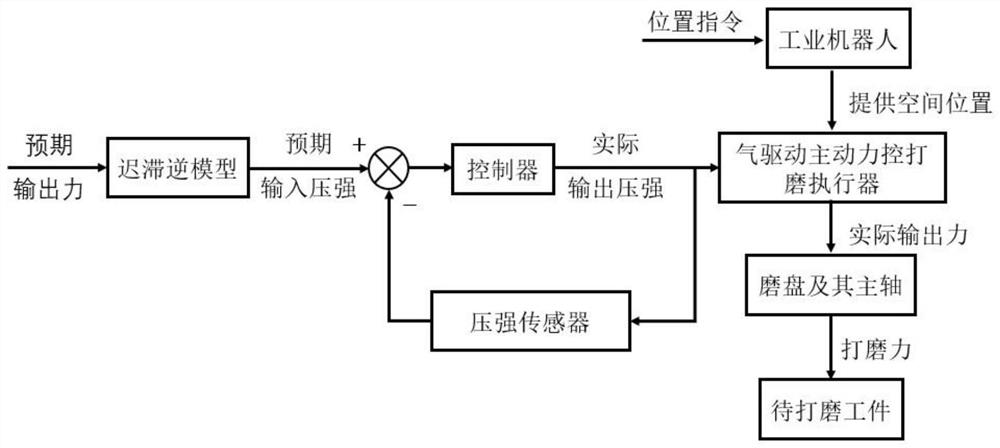

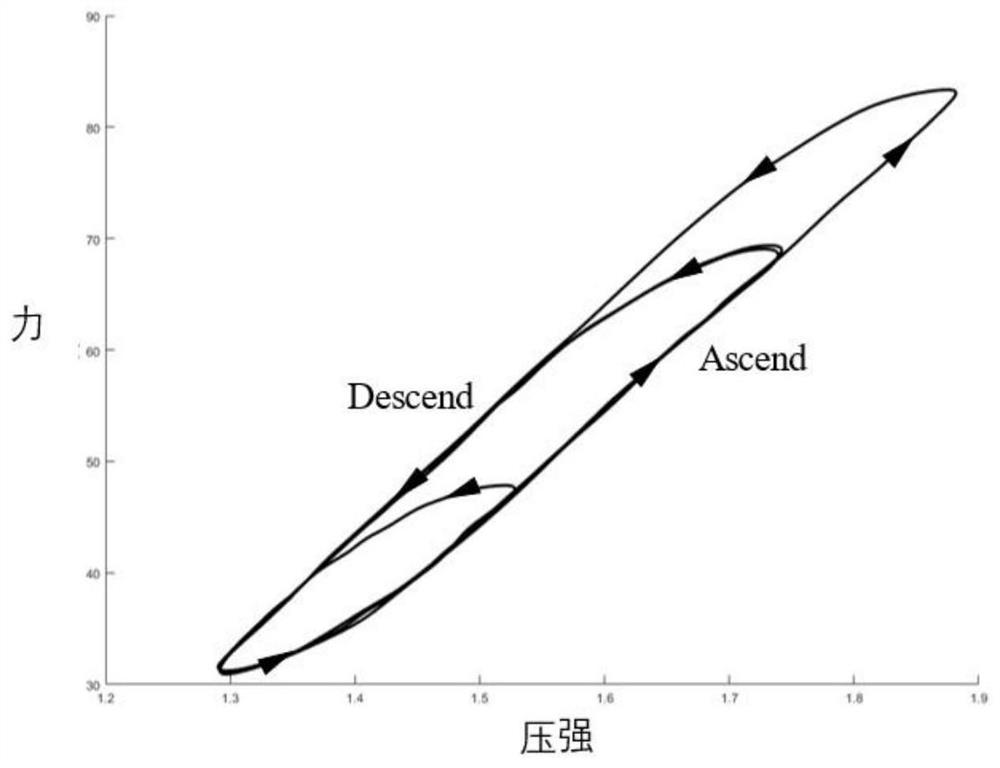

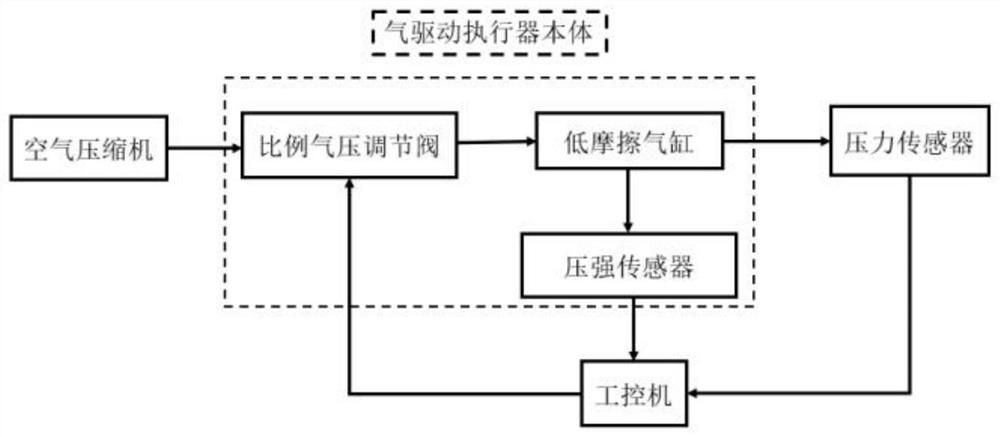

[0100] The present invention provides a data-driven hysteresis modeling method for the above-mentioned deficiencies in the prior art. This method combines the inherent dynamic nonlinear characteristics of the hysteresis phenomenon, uses Gaussian process regression to establish a first-order differential equation that expresses the relationship between hysteresis input and output, and then uses the corresponding data set obtained from the experiment to train the Gaussian process regression model. Output the explicit expression of the input and output differential equations, and use the numerical method to solve the differential equations to complete the prediction of the corresponding output under the given input. The air-driven grinding actuator is directly compensated by solving the hysteresis inverse model, so as to realize the precise semi-closed-loop control of the output force through the closed-loop control of the air pressure. Therefore, without considering the specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com