Tool changing device and method for steel rail repairing equipment

A tool changing device and rail technology, applied in positioning devices, metal processing equipment, clamping, etc., can solve inconvenience and other problems, and achieve the effect of accurate positioning, convenient tool replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

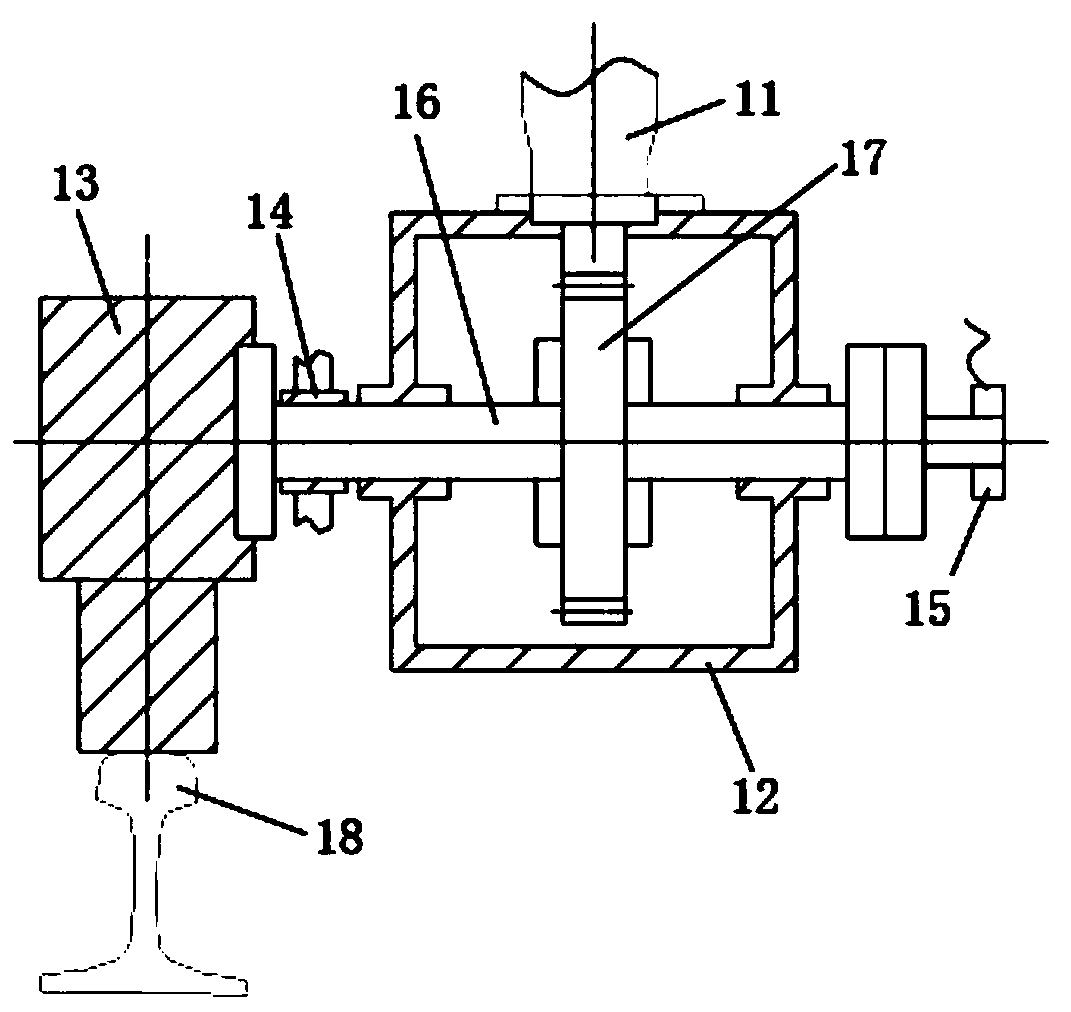

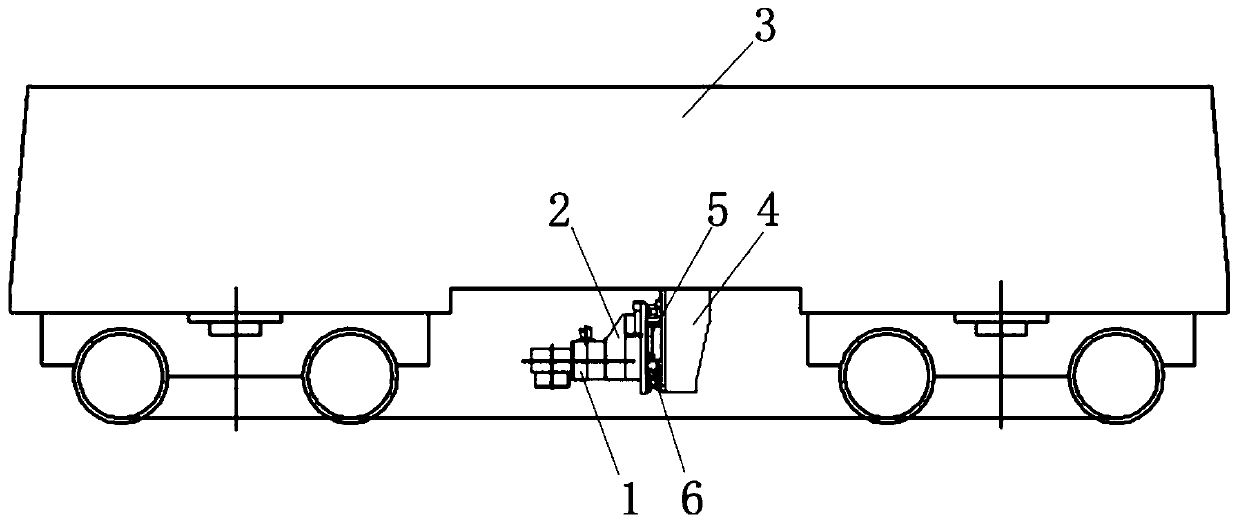

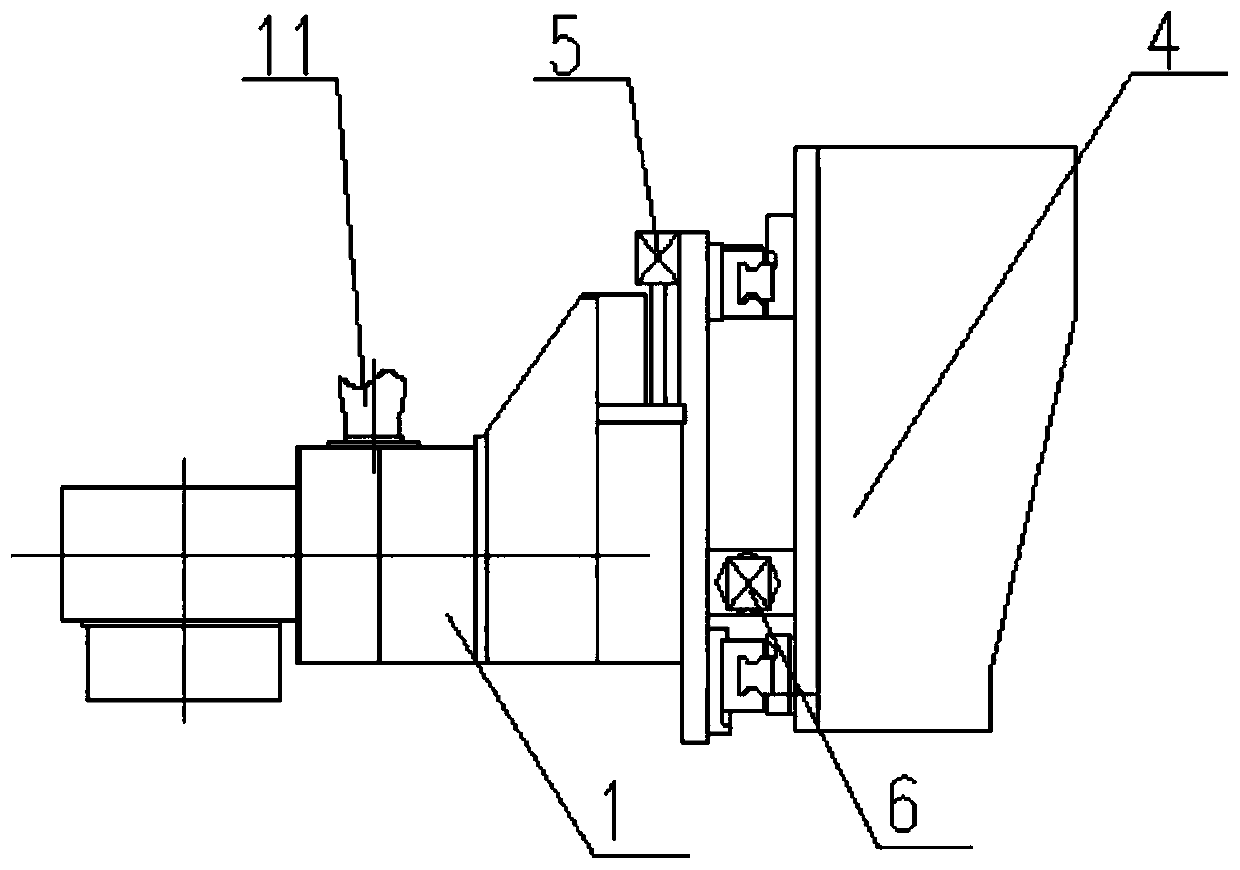

[0030] Combine below Figure 1-3 Describe in detail the preferred technical scheme of the tool changer for rail repairing equipment:

[0031] A tool changing device for rail repair equipment, including a transmission box 12, the transmission box 12 is equipped with a first transmission shaft 16 in the horizontal direction, and one end of the first transmission shaft 16 is respectively equipped with a milling cutter system 13 and a locking system from left to right. Mechanism 14, the other end of the first transmission shaft 16 is equipped with a position feedback mechanism 15, the milling cutter disc system 13 includes a milling cutter disc, the transmission box 12 is equipped with a second transmission shaft 17 in the vertical direction, and the top of the transmission box 12 is equipped with a third driver 11 , the third driver 11 is connected to the second transmission shaft 17, the axis of the third driver 11 is perpendicular to the rotation axis of the milling cutter syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com