Welding fixing support for elliptical pipe

A technology for fixing brackets and elliptical tubes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as inability to apply elliptical tubes, eccentric shaking of elliptical tubes, and inconvenient welding methods, so as to facilitate promotion and support Good resistance and improved welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

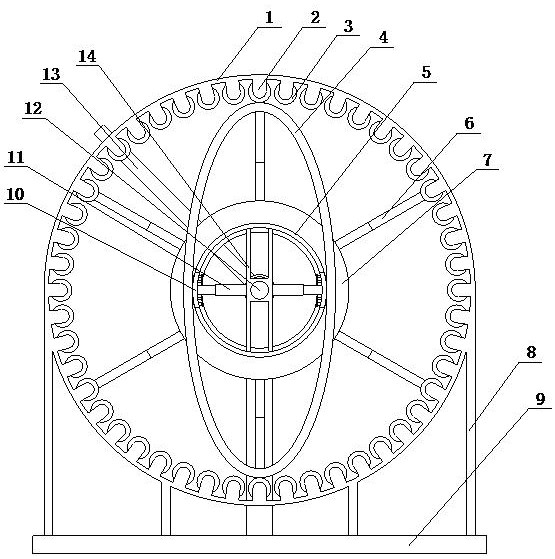

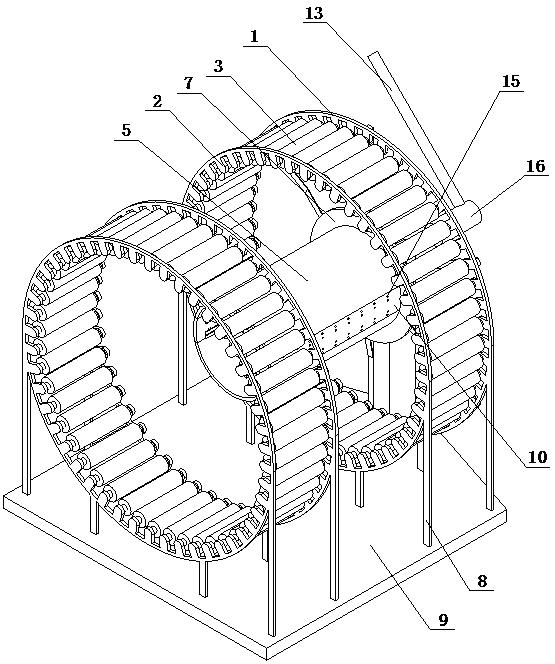

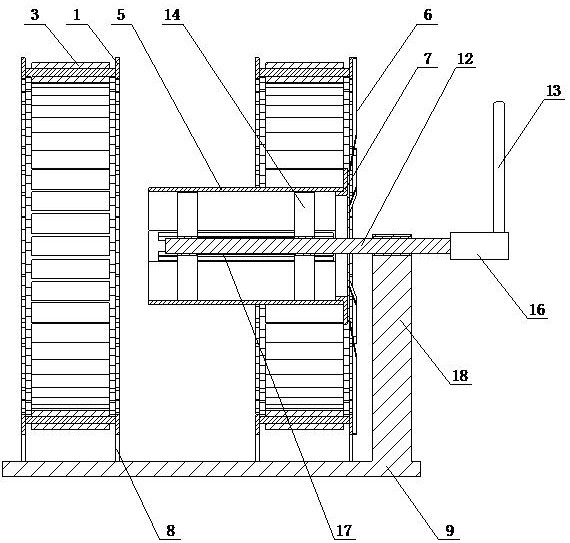

[0018] A welded fixing bracket for an elliptical pipe of the present invention is realized in this way, and is composed of an outer support device and an inner support device, the outer support device outer ring frame (1), roller frame (2), rotating roller (3), support pole ( 8) and the base (9), two coaxial outer rings (1) are placed on the base (9) through the support pole (8), and the outer ring (1) is composed of two coaxial rings , the inner wall of the ring is equipped with multiple roller stands (2) at equal angles along the circumference, the roller stands (2) on the two rings are opposite one by one, and the two opposite roller stands (2) are placed between There are rotating rollers (3), and a plurality of rotating rollers (3) on the outer ring frame (1) cooperate to form a cylindrical surface, and the inner supporting device is an inner ring frame (5), a connecting rod (6), a fixed support ring ( 7), fixed support plate (10), hydraulic rod (11), rotating shaft (12),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com