Damping type uncoiler

An uncoiler and damping technology, which is applied in the field of uncoilers, can solve the problems of heavy head, affecting stamping accuracy, and large driving inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiments.

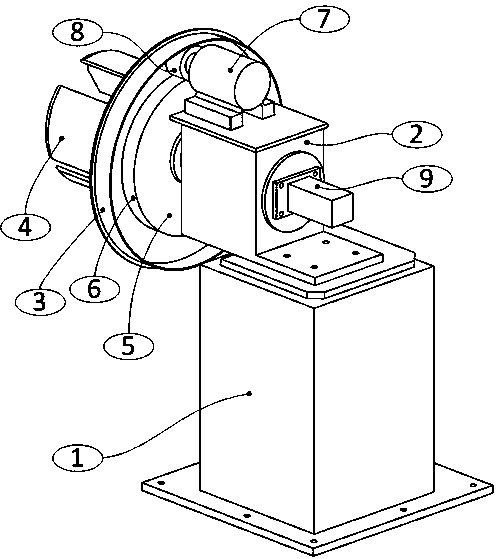

[0012] Such as figure 1 As shown, it is a structural schematic diagram of a damping type uncoiler of the present invention, including a support base 1, which is set at a certain height as required, so that after the strip steel coil is erected on the machine, it can be suspended from the ground, and the There is a control system; a bearing support seat 2 is provided on the support base 1, and the uncoiler head 3 is fixed on the bearing support seat 2 through the rotating bearing support system; the uncoiler head 3 has an expansion-opening type The claw system 4 fixes the strip steel coil to be processed through the opening and closing of the claw system 4 .

[0013] The difference of the present invention is that, on the back side of the uncoiler head 3, a drive disc 5 is arranged, and the drive disc 5 is closely connected with the uncoiler head 3 and rotates synchronously...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com