Phosphorus-doped Mn0.3Cd0.7S nanorod photocatalyst as well as preparation method and application thereof

A technology of photocatalysts and nanorods, applied in physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as complex process flow and high cost, and achieve methods that are easy to operate, easy to implement, and increase solar spectral response range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

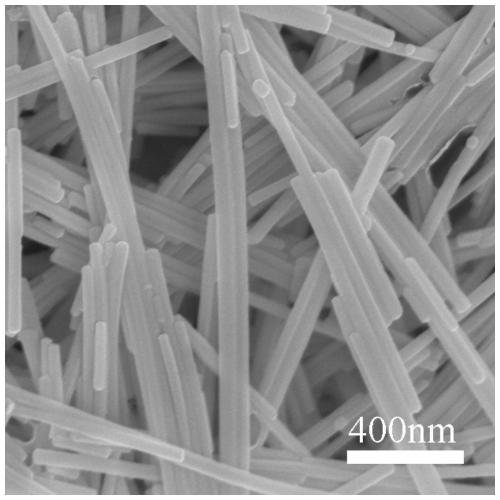

[0043] A phosphorus-doped Mn 0.3 Cd 0.7 The preparation method of S nanorod photocatalyst comprises the steps:

[0044] (1) 190mg of NaH 2 PO 2 ·H 2 O, 200 mg of Mn 0.3 Cd 0.7 The S catalysts were mixed, and then ball milled for 20min at a speed of 300rpm to obtain a mixture;

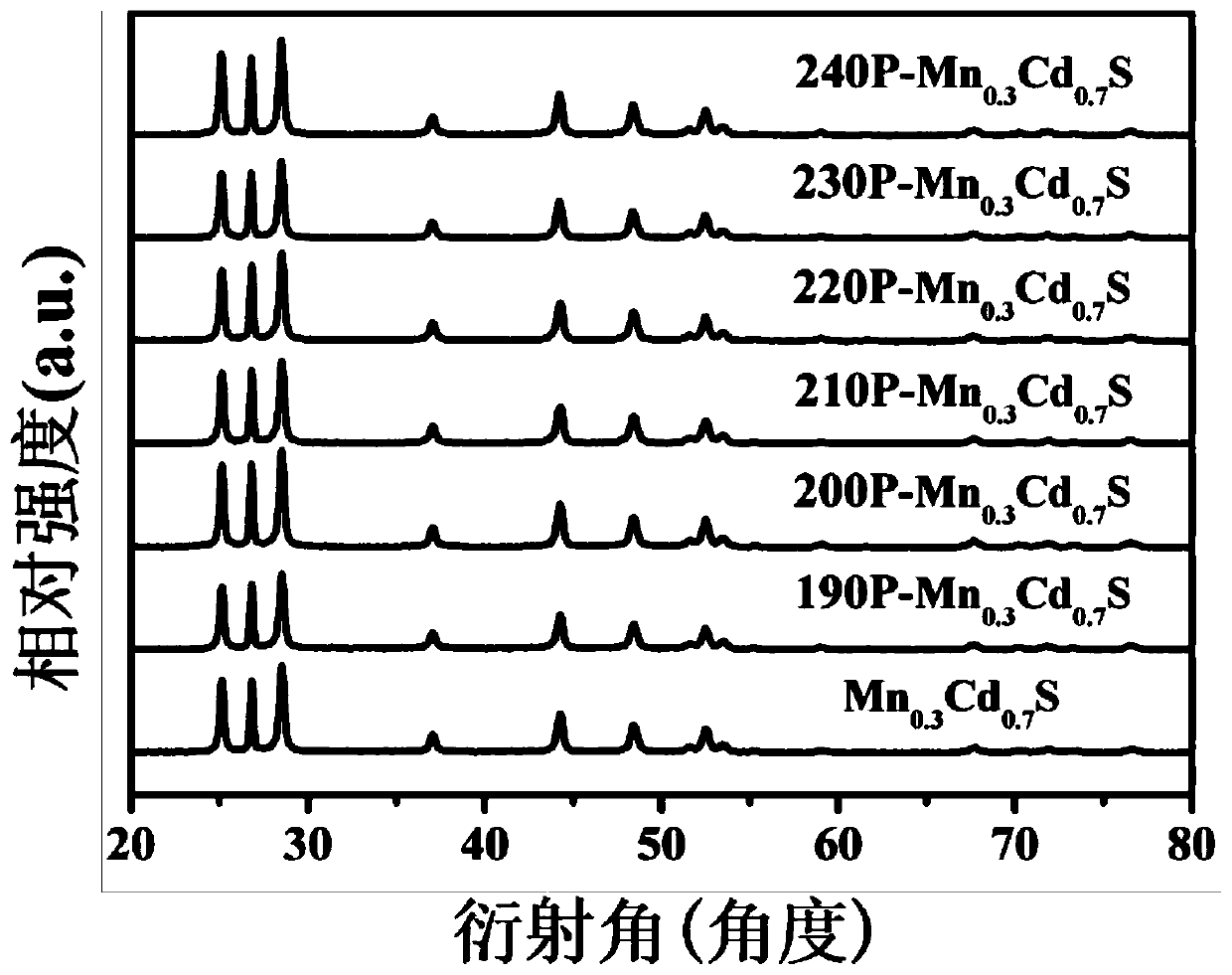

[0045] (2) Transfer the above mixture to a tube furnace, and feed it with argon. After 30 minutes, heat up under an argon protective atmosphere at a rate of 2°C.min -1 , heated to 300°C for calcination for 2h. Cool to room temperature, wash alternately with ethanol and water, filter to get the precipitate, and dry to obtain the phosphorus-doped Mn 0.3 Cd 0.7 S nanorod photocatalyst. The phosphorous doping Mn that embodiment 1 makes 0.3 Cd 0.7 S nanorod photocatalyst labeled as 190P-Mn 0.3 Cd 0.7 S.

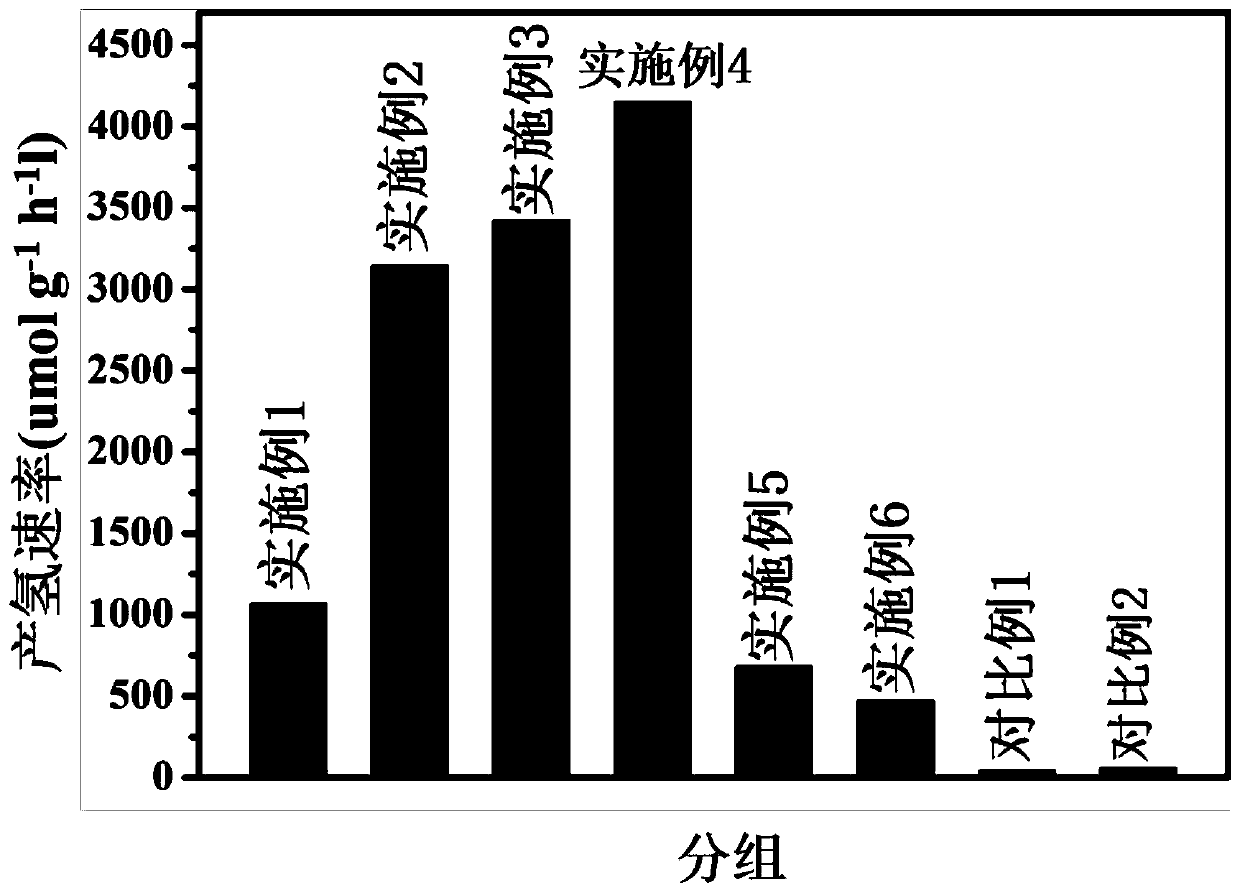

[0046] Under the irradiation of a 300WXe lamp, the reaction temperature is 15°C, and the phosphorous-doped Mn prepared in Example 1 0.3 Cd 0.7 S nanorod photocatalyst (i.e. 190P-Mn 0.3 Cd ...

Embodiment 2

[0048] A phosphorus-doped Mn 0.3 Cd 0.7 The preparation method of S nanorod photocatalyst comprises the steps:

[0049] (1) Add 200mg of NaH 2 PO 2 ·H 2 O, 200 mg of Mn 0.3 Cd 0.7 The S catalysts were mixed, and then ball milled for 20 minutes at a rotating speed of 300 rpm to obtain a mixture;

[0050] (2) Transfer the above mixture to a tube furnace, and feed it with argon. After 30 minutes, heat up under an argon protective atmosphere at a rate of 2°C.min -1 , heated to 300°C for calcination for 2h. Cool to room temperature, wash, filter to get the precipitate, and dry to obtain the phosphorus-doped Mn 0.3 Cd 0.7 S nanorod photocatalyst. The phosphorous doping Mn that embodiment 2 makes 0.3 Cd 0.7 S nanorod photocatalyst labeled 200P-Mn 0.3 Cd 0.7 S.

[0051] Under the irradiation of 300WXe lamp, under the condition of reaction temperature 15 ℃, the phosphorus-doped Mn prepared in embodiment 2 0.3 Cd 0.7 S nanorod photocatalyst (i.e. 200P-Mn 0.3 Cd 0.7 Th...

Embodiment 3

[0053] A phosphorus-doped Mn 0.3 Cd 0.7 The preparation method of S nanorod photocatalyst comprises the steps:

[0054] (1) 210mg of NaH 2 PO 2 ·H 2 O, 200 mg of Mn 0.3 Cd 0.7 The S catalysts were mixed, and then ball milled for 20min at a speed of 300rpm to obtain a mixture;

[0055] (2) Transfer the above mixture to a tube furnace, and feed it with argon. After 30 minutes, heat up under an argon protective atmosphere at a rate of 2°C.min -1 , heated to 300°C for calcination for 2h. Cool to room temperature, wash, filter to get the precipitate, and dry to obtain the phosphorus-doped Mn 0.3 Cd 0.7 S nanorod photocatalyst. The phosphorous doping Mn that embodiment 3 makes 0.3 Cd 0.7 S nanorod photocatalyst labeled as 210P-Mn 0.3 Cd 0.7 S.

[0056] Under the irradiation of a 300WXe lamp, when the reaction temperature was 15°C, the phosphorous-doped Mn prepared in Example 3 0.3 Cd 0.7 S nanorod photocatalyst (210P-Mn 0.3 Cd 0.7 The hydrogen production rate of S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com