Anti-galloping phase-to-phase spacer

A technology of interphase spacer and sub-conductor spacer, which is applied in the field of overhead transmission lines, can solve problems such as broken connection fittings, broken pressure equalizing ring brackets for insulators, etc., and achieves the effect of solving the problem of easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This application is an interphase spacer, which uses a damping device, which is different from the conventional structure. The core part of the damping device is a constant force spring, which is preset between the sub-conductor spacer and the insulator 4. The interphase spacer of the structural type can be designed according to the use environment to design the force of the constant force spring, so as to ensure that the interphase spacer has better damping performance and avoid metal fracture due to galloping and other reasons.

[0034] A spacer between phases is designed, which can hold the wire stably and effectively, and reduce the breakage of connecting fittings and other fittings caused by dancing. The interphase spacer employs a damping mechanism.

Embodiment 2

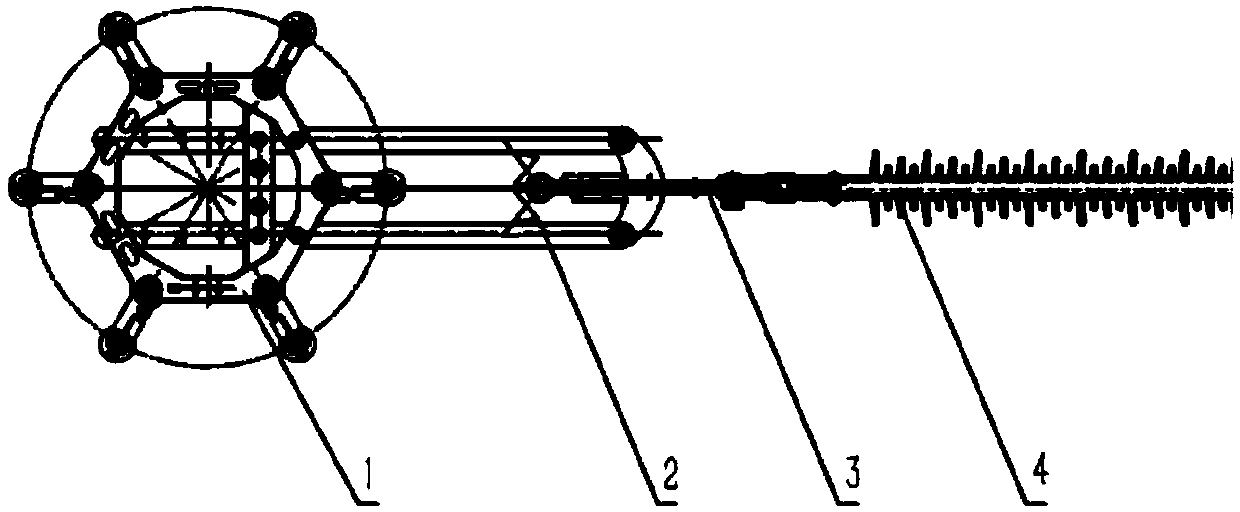

[0036] An anti-dancing spacer between phases, comprising: a sub-conductor spacer 1, a damping device 2 and a connecting fitting 3;

[0037] The sub-conductor spacer 1 is connected to the connecting fitting 3 through the damping device 2 .

[0038] The damping device 2 includes:

[0039] Two first connecting rods of the same length, a crescent-shaped metal frame and a constant force spring;

[0040] The two ends of the connecting rod are connected to the two ends of the crescent-shaped metal frame;

[0041] The constant force spring is arranged in the middle of the concave side of the crescent-shaped metal frame along a direction parallel to the first connecting rod, and the length of the constant force spring is smaller than the length of the first connecting rod.

[0042] The length of the constant force spring is set based on the use environment of the anti-flying spacer bar.

[0043] The sub-wire spacer 1 includes:

[0044] a hexagonal frame and a clip body connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com