Power battery cover plate and manufacturing method thereof

A technology of power battery and manufacturing method, which is applied to battery pack components, battery box/jacket, small-sized battery/battery pack, etc. Efficiency, improving the manufacturing yield, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

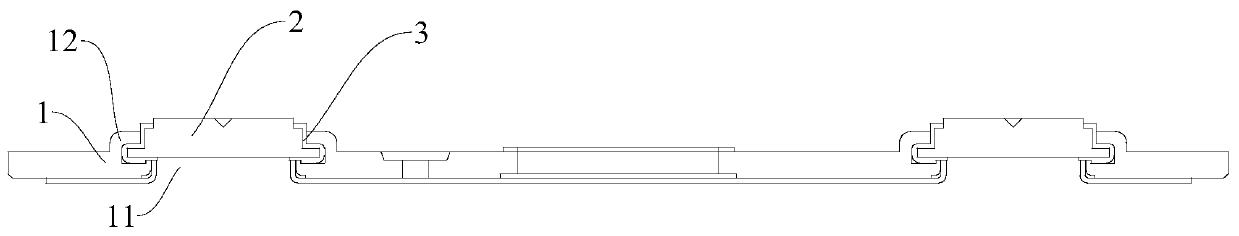

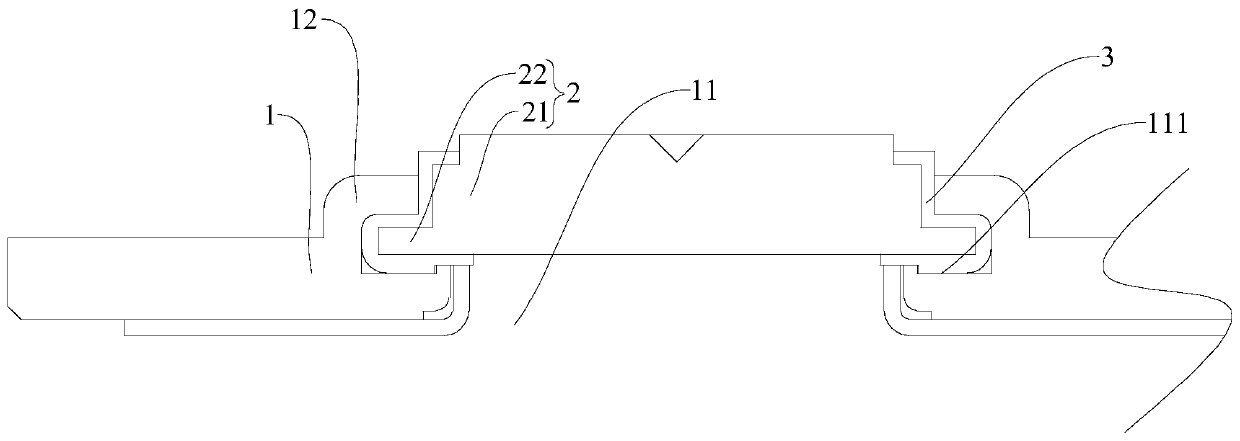

[0047] Refer below Figure 1-Figure 4A power battery cover plate according to a specific embodiment of the present invention is described.

[0048] Such as Figure 1-Figure 4 As shown, the power battery cover plate of this embodiment includes a top cover 1, a pole 2 and a first rubber covering part 3, and a countersunk hole 11 is provided on the top cover 1, and the countersunk hole 11 has a first stepped surface 111. The cover 1 is provided with a flange 12 arranged around the countersunk hole 11. The pole 2 includes a body 21 and a protruding ring 22 connected to the body 21. The protruding ring 22 is connected to the lower end surface of the body 21, and the lower end surface of the protruding ring 22 stop on the first stepped surface 111 . The flange 12 is crimped on the protruding ring 22 after being completed, and the first rubber covering part 3 covers the surface of the main body 21 and the protruding ring 22 .

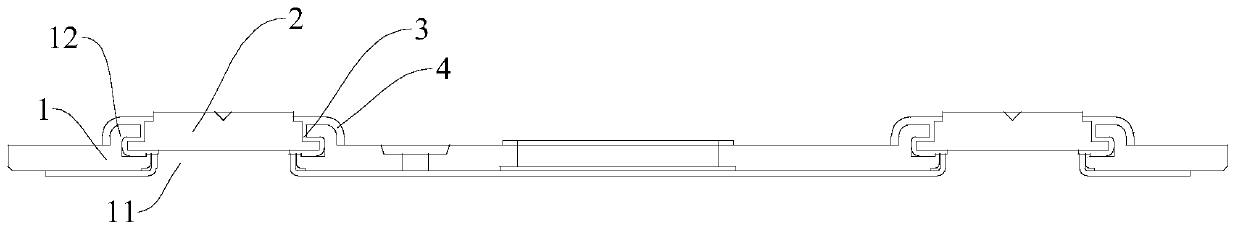

Embodiment 2

[0050] Such as Figure 5 As shown, the power battery cover plate of this embodiment is similar in structure to the power battery cover plate of the above-mentioned embodiment, the difference is that the cover plate of this embodiment also includes a second rubber covering member covering the flange 12 4.

Embodiment 3

[0052] Such as Figure 6 As shown, the power battery cover plate of this embodiment is similar in structure to the power battery cover plate of the above embodiment, the difference is that the pole 2 of this embodiment is formed as a structure in which the protruding ring 22 surrounds the body 21 . And the body 21 of the pole 2 is disposed through the counterbore 11 , and the lower end surface of the protruding ring 22 abuts against the first stepped surface 111 .

[0053] Refer below Figure 7 The specific steps of the manufacturing method of the power battery cover plate according to the embodiment of the present invention are described.

[0054] The invention also discloses a method for manufacturing the power battery cover, the steps of the method include:

[0055] S1: forming a first rubber covering 3 on the outer peripheral surface of the pole 2;

[0056] S2: placing the pole 2 in the counterbore 11 and making the protruding ring 22 abut against the first stepped surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com