Fault detection method for loose and missing key nuts of small parts bearings of railway wagons

A railway freight car, nut loosening technology, applied in computer parts, character and pattern recognition, image data processing and other directions, can solve the problems of low accuracy, low efficiency, high cost, and achieve improved efficiency, unified operating standards, and detection efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

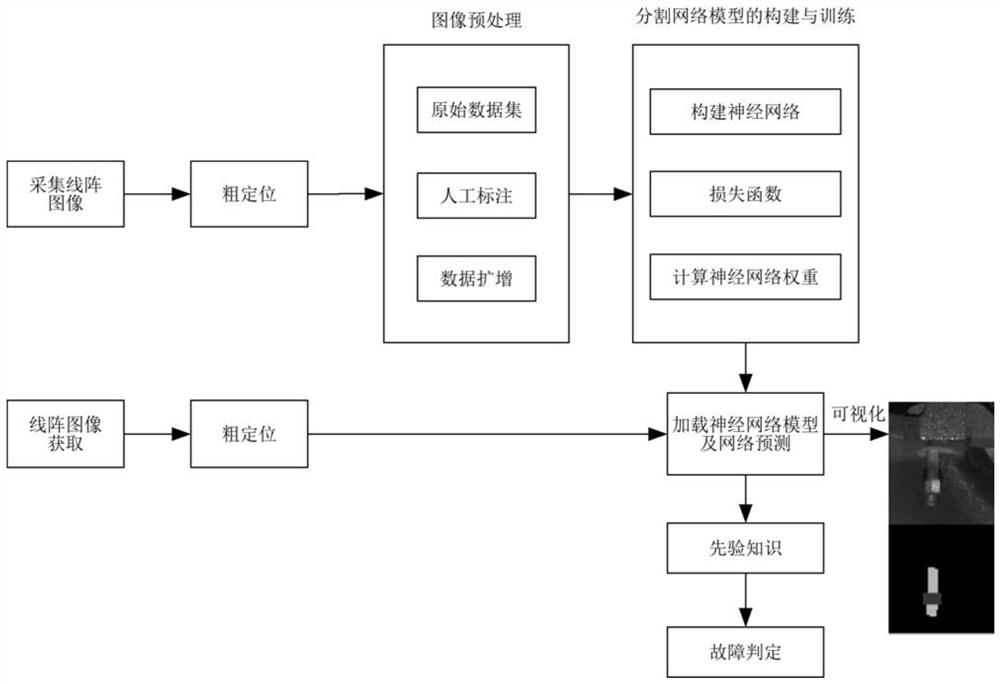

[0042] Specific implementation mode one: refer to figure 1 To describe this embodiment in detail,

[0043] The fault detection method for the looseness and loss of the key nut of the small component bearing of the railway freight car includes the following steps:

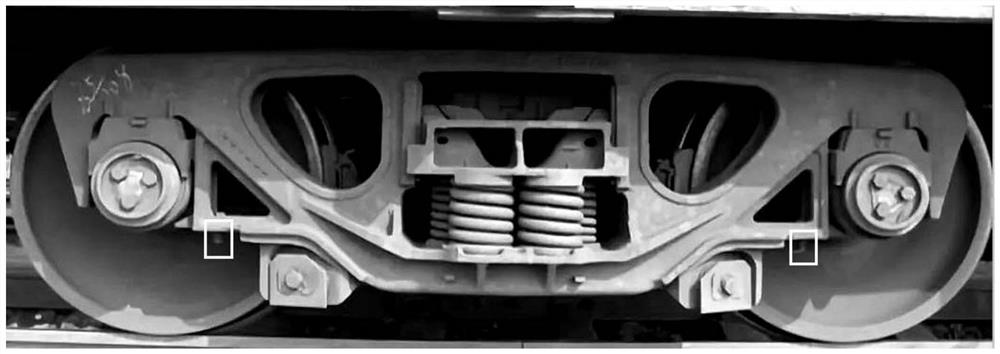

[0044] 1. Image Collection

[0045] Fixed equipment around the track of the truck is equipped with a camera or video camera to take pictures of the moving truck. After the truck passes through the equipment, a high-definition grayscale full-vehicle image is obtained. Image quality is mainly affected by two aspects, one is the influence of natural conditions: rain, snow, mud stains, light, etc.; the other is the influence of man-made conditions: oil stains, black paint, differences in equipment installation, etc.

[0046] Therefore, there is a large variation between the obtained key nut images. In order to enhance the robustness of the recognition algorithm, in the process of collecting image data, we try our bes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com