Method for predicting outlet flow non-uniformity coefficient of turbine gas collection cavity

A technology of uniform coefficient and outlet flow, applied in neural learning method, physical realization, biological neural network model, etc., can solve the problem of uneven outlet flow, achieve the effect of small calculation load, strong global approximation ability, and reduce calculation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings.

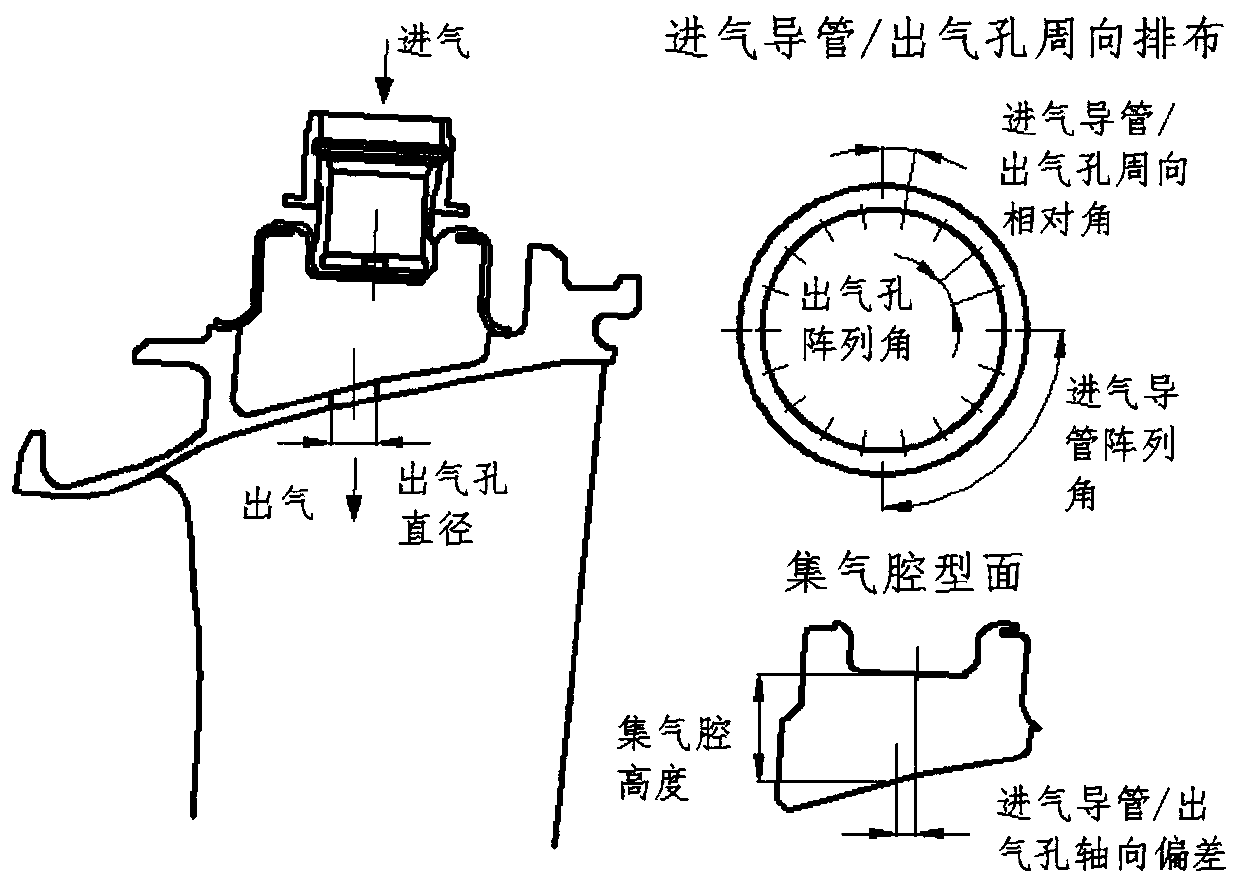

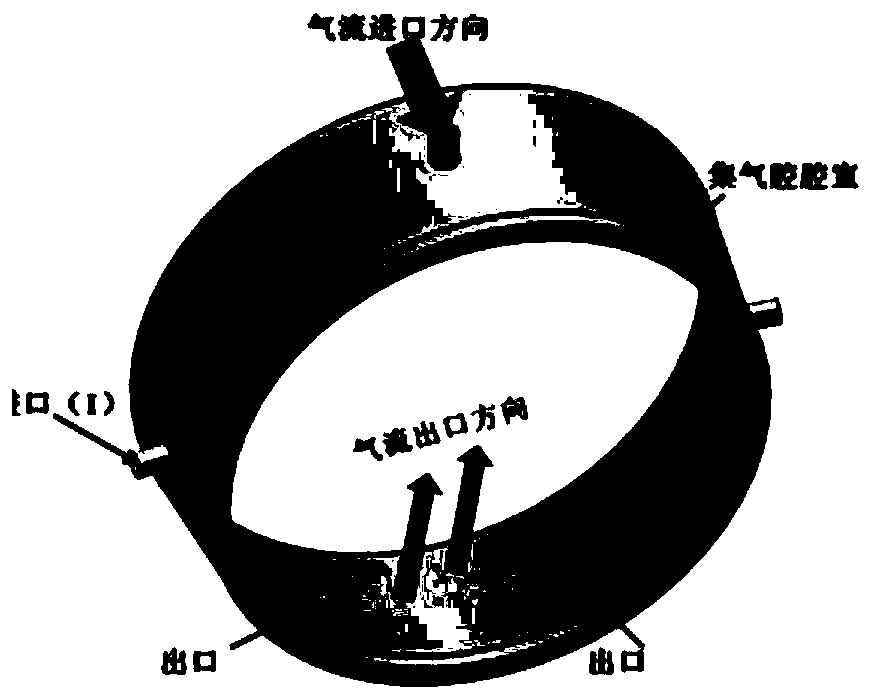

[0037] Such as figure 1 A physical model of the gas collection chamber is shown, and the input parameters of the selected prediction model are as follows: the diameter of the intake duct d j , the number of intake ducts N j , air outlet diameter d c , the number of vent holes N c , the height H of the air collection chamber, the axial distance deviation ΔL between the inlet duct and the outlet hole, and the circumferential relative angle Δβ between the inlet duct and the outlet hole.

[0038] The variation range of each input parameter is as follows: d j The range of change is 20~40mm; N j The range of change is 2 to 6; d c The range of change is 6~15mm; N c The variation range of H is 60~100; the variation range of H is 10~30mm; the variation range of ΔL is 0~30mm; the variation range of Δβ is 0~30°.

[0039] According to the change of the input parameters in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com