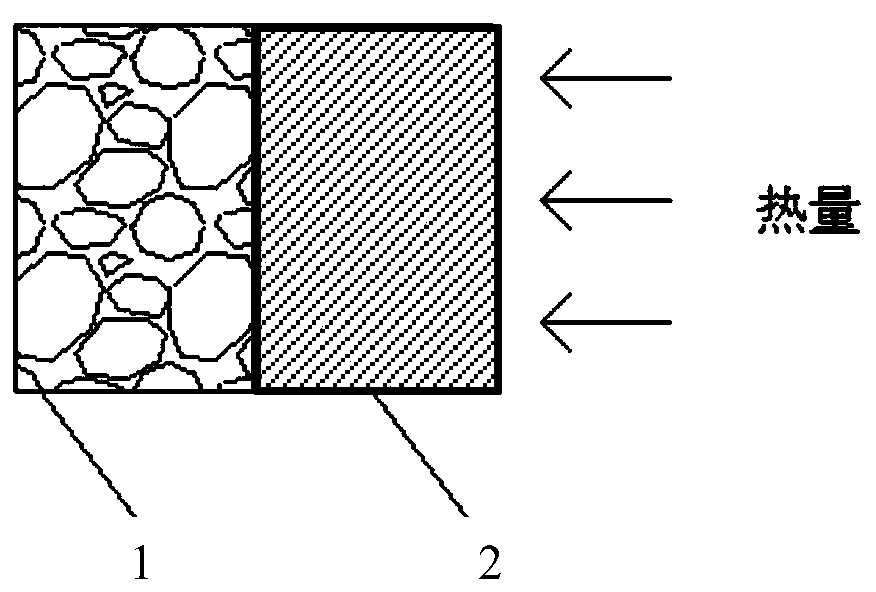

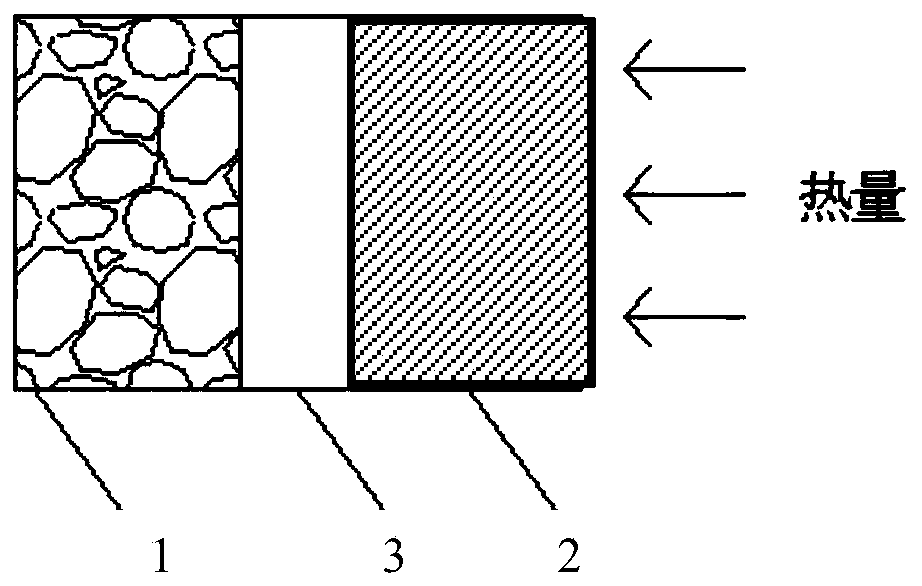

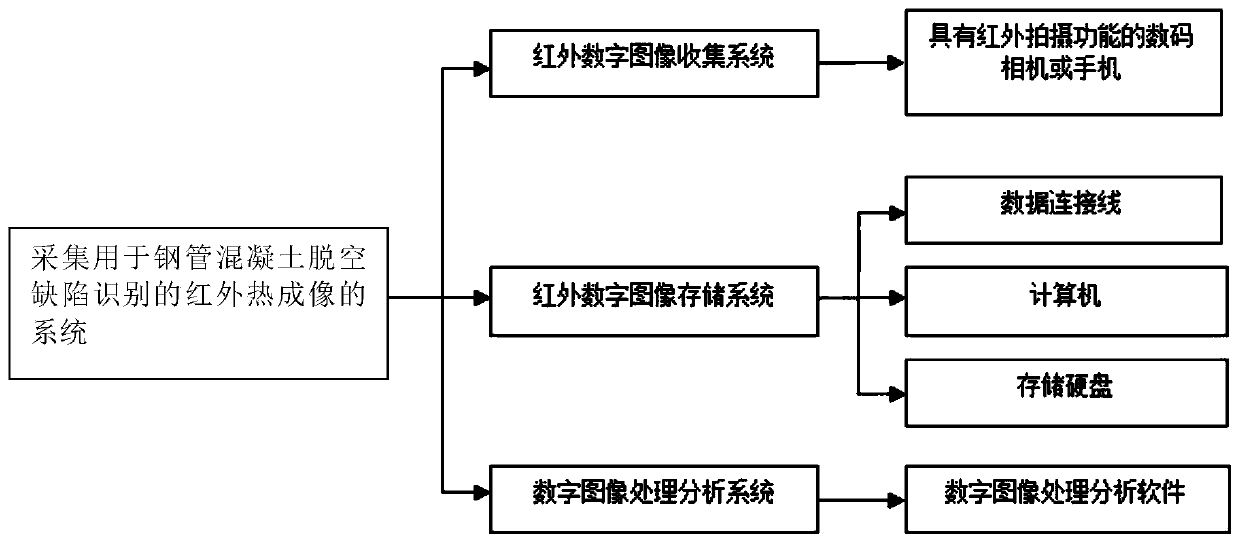

Method for identifying void defects of concrete-filled steel tube member based on infrared thermal imaging

A technology of steel pipe concrete and infrared thermal imaging, which is applied in the field of building material detection, can solve the problems that the hollow part cannot be detected by ultrasonic, and achieve the effects of low test cost, saving manpower and material resources, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] First of all, it needs to be explained that the present invention relates to infrared image temperature identification and calculation based on the identification result, and is an application of computer technology in the field of information security technology. During the implementation of the present invention, the application of multiple software function modules will be involved. The applicant believes that, after carefully reading the application documents and accurately understanding the realization principle and purpose of the present invention, combined with existing known technologies, those skilled in the art can fully implement the present invention by using their software programming skills. The aforementioned software functional modules include but are not limited to: infrared digital image processing software, digital image processing and analysis system, etc. All mentioned in the application documents of the present invention belong to this category, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com