Treatment method of alkali metal heat pipe liquid absorption core

A processing method and a liquid absorbing core technology, which are applied in the field of nuclear reactors, can solve the problems of increased volume and limited heat transfer, and achieve the effect of reducing the volume and improving the heat transfer limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] The invention provides a treatment method for an alkali metal heat pipe liquid-absorbing core, comprising the following steps:

[0037] Step 1. Confirm the basic principles

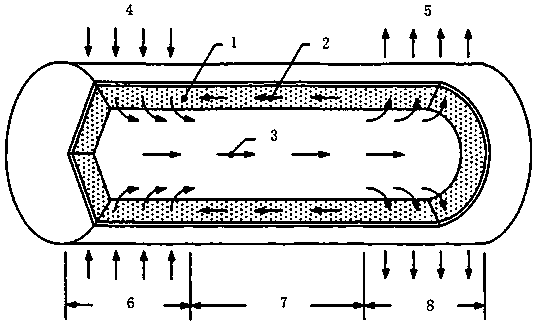

[0038] Such as figure 1 As shown, according to the cotter theory, the force balance relationship of the heat pipe during operation is as follows:

[0039] ΔP ca ≥ΔP v +ΔP l +ΔP d,g ±ΔP g (1)

[0040] in,

[0041] ΔP ca is the capillary force, that is, the driving force of the fluid circulation inside the heat pipe, provided by the liquid-absorbing core;

[0042] ΔP v is the gas phase frictional pressure drop (steam flows from the evaporation section to the condensation section);

[0043] ΔP l is the liquid phase friction pressure drop (the condensed liquid flows back from the condensation section to the evaporation section);

[0044] ΔP d,g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com