Ship lift tower structure provided with thin pile raft foundation and layered strongly-constrained box girders

A technology of raft foundation and ship lift, which is applied in basic structure engineering, construction, etc., can solve the problems of unfavorable secondary stress of navigable aqueduct structure, affecting the safe operation of water stop, large plane torsion effect, etc., and achieves the control of uneven settlement , the effect of increasing lateral stiffness and reducing secondary stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

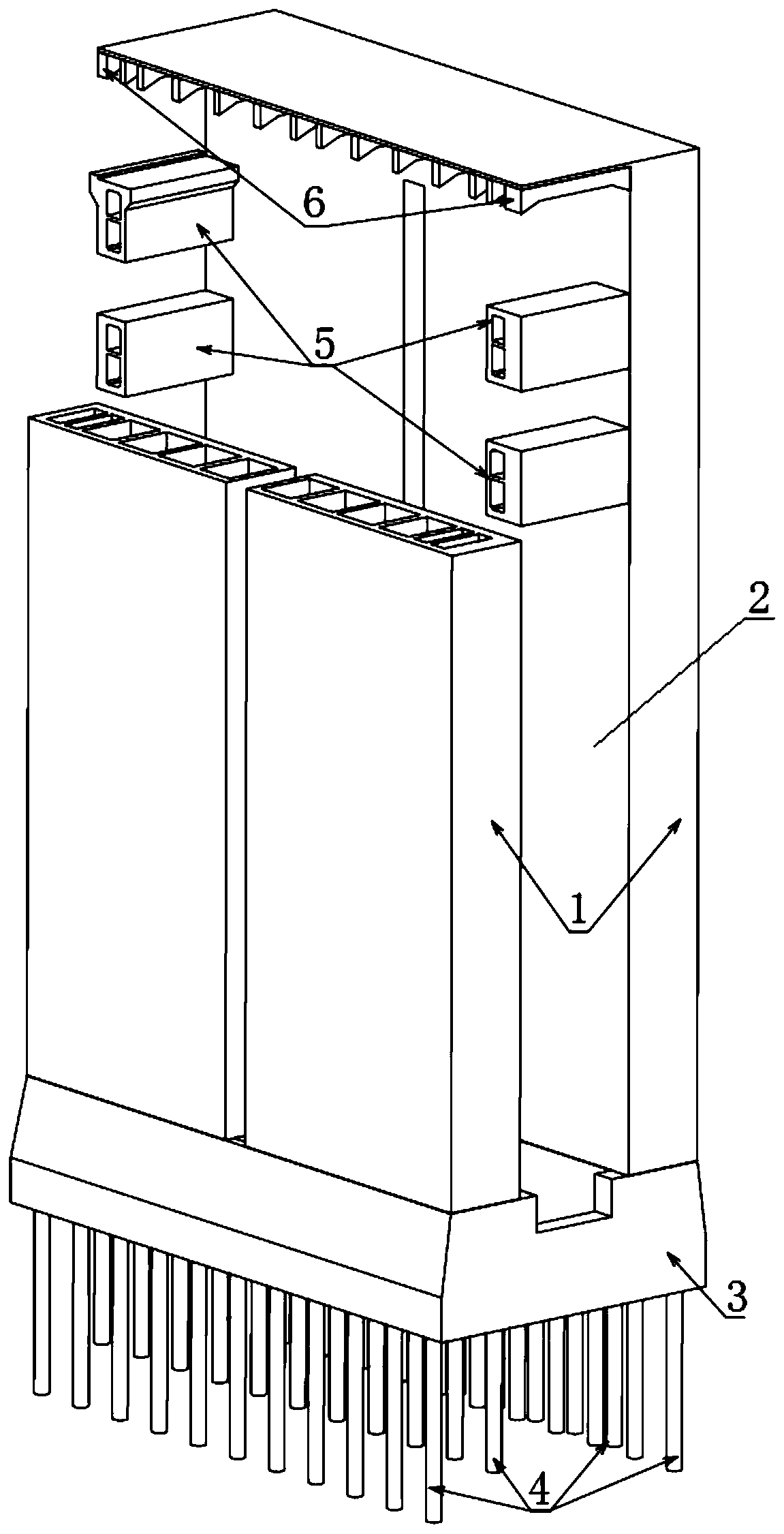

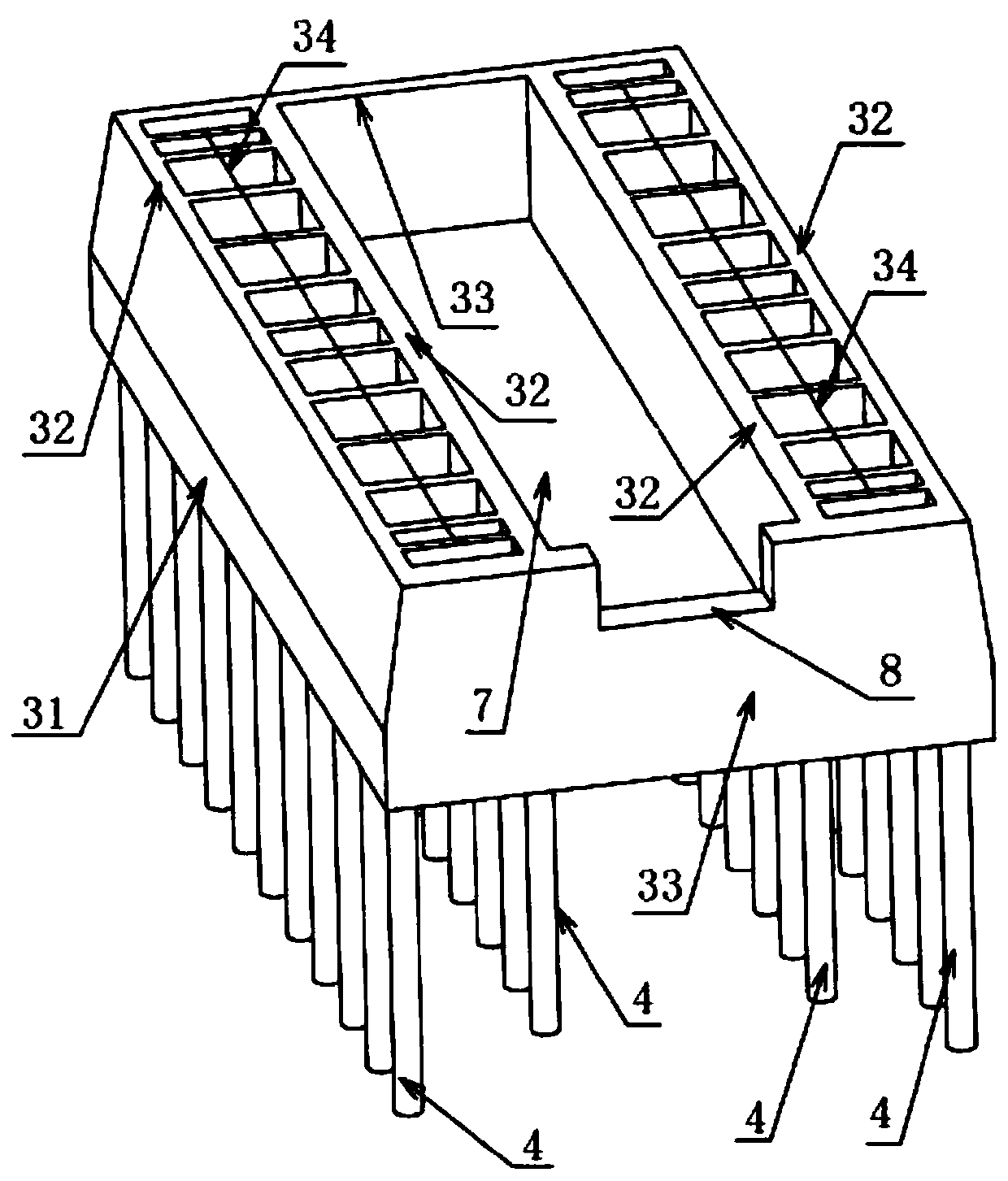

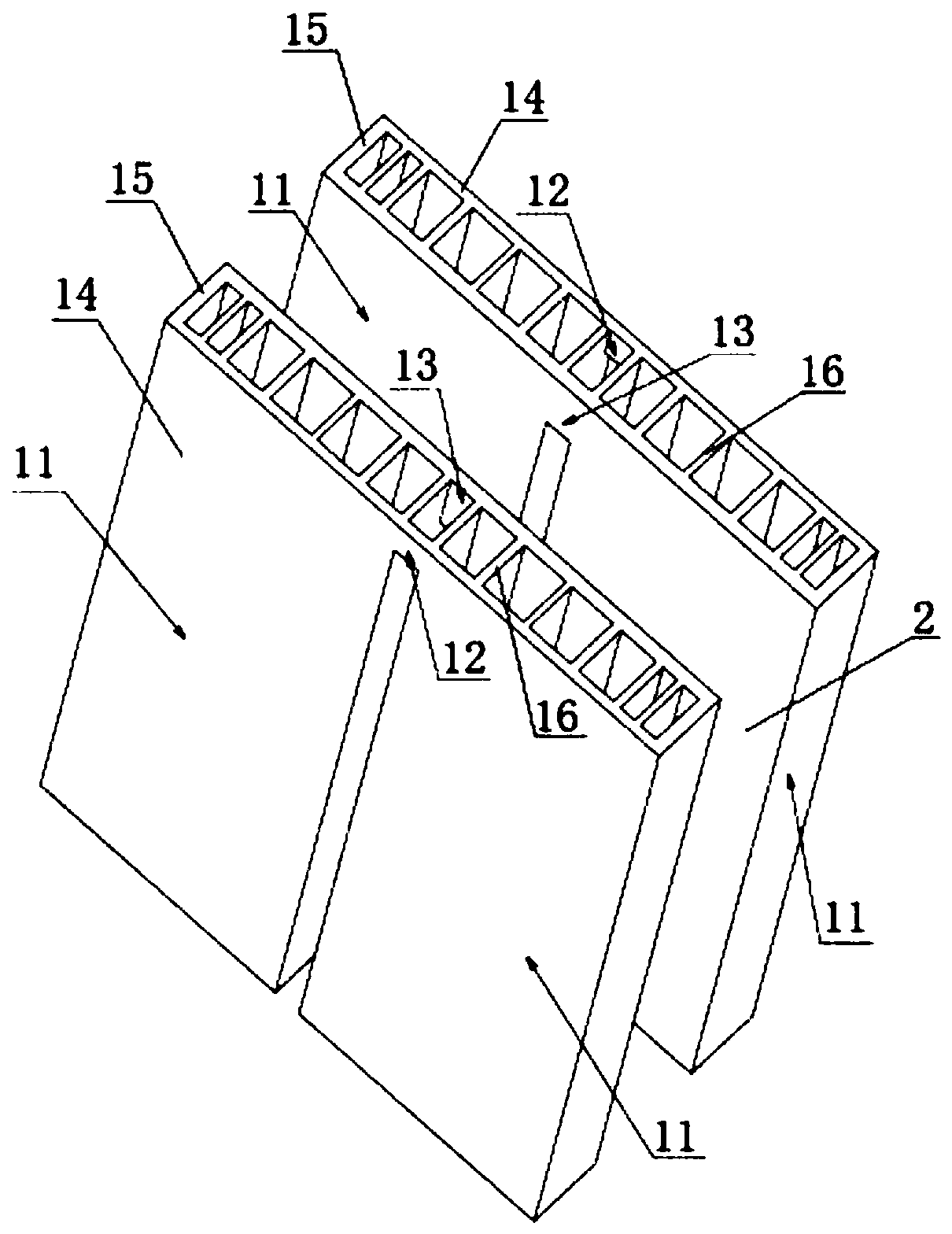

[0033] like figure 1 As shown, the ship lift tower structure of the present invention is provided with sparse pile raft foundation and layered strong restraint box girder, including the tower main body, and the tower main body includes two left and right symmetrical tower groups 1, two tower groups The space between 1 forms a ship compartment 2, and a raft foundation 3 is arranged directly under the main body of the tower column, and a pile group including several piles 4 is arranged directly under the foundation 3, and the piles 4 are inserted into the foundation of the ship lift In the upper part of the two tower column groups 1, there are several layers of connecting box girder groups. The two ends of 5 are fixedly connected to the two tower column groups 1 respectively, and a top beam group including several top beams 6 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com