Annealing treatment method and device for reducing internal stress of crystal

An annealing treatment and internal stress technology, applied in the directions of post-processing, crystal growth, post-processing details, etc., can solve the problems of reducing the productivity of the crystal growth furnace, cannot be eliminated, and the radial temperature gradient of the crystal cannot be changed, so as to solve the cracking of the crystal ingot , Reduce radial stress and eliminate residual thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

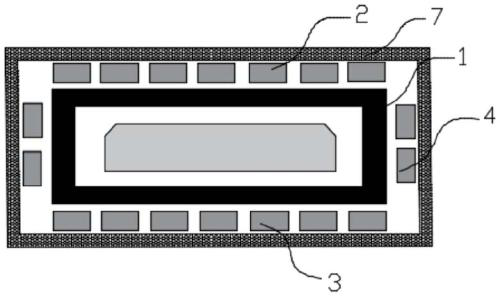

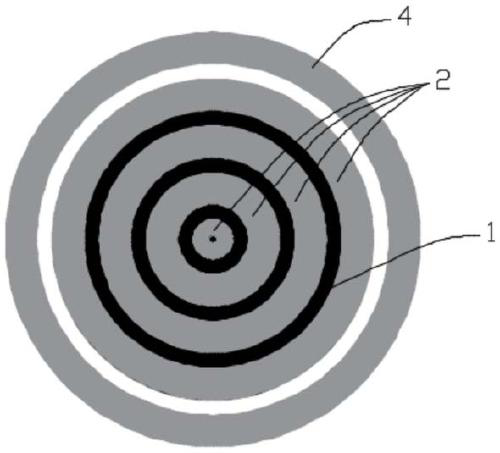

[0050] Embodiment 1: The present invention is used for the device of silicon carbide crystal annealing treatment, and its specific structure is as follows:

[0051] Such as Figure 1~3 As shown, the device for crystal annealing treatment of the present invention includes a crucible 1 and a heating device for heating the crucible 1, and the heating device includes a plurality of first heating rings 2 distributed above the crucible 1, and a plurality of first heating rings 2 distributed below the crucible. A plurality of second heating rings 3, and a plurality of third heating rings 4 arranged on the side of the crucible; wherein the plurality of first heating rings 2 are concentrically arranged with the upper center of the crucible 1 as the center, and the plurality of second heating rings 3 The crucible 1 is set concentrically with the center below the center of the crucible 1 , and the first heating ring 2 and the second heating ring 3 are symmetrically set.

[0052] In the ...

Embodiment 2

[0063] Embodiment 2: the annealing treatment method of crystal

[0064] According to an embodiment of the present application, a method for crystal annealing using the device described in Example 1 includes:

[0065] (1) Preparatory stage: Put the crystal (6 inches) to be annealed into crucible 1, vacuumize and feed inert gas (Ar gas), so that the pressure in crucible 1 is controlled at 200-900mbar, and the flow rate of Ar gas is controlled at 50- 500ml / min;

[0066] (2) Heating stage: if Figure 4 As shown, simultaneously control all heating rings (first heating rings A1, A2, A3, A4, second heating rings B1, B2, B3, B4, third heating rings S1, S2) to start synchronous heating, and heat to T1 (1700 ~2300℃), keep warm for 1~10h;

[0067] During the crystal growth process, the temperature of the growth surface is higher than that of the seed crystal plane, and the temperature of the crystal center on the same plane is lower than that of the crystal edge. Therefore, at this s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com