Film conveying mechanism and extrude-emptying mechanism of automatic vertical type filling and packaging machine

A technology of conveying mechanism and packaging machine, applied in the field of food packaging, can solve the problems of unfavorable sealing and welding function of sealing and welding device, bearing damage, shaft deformation, etc., and achieve the effect of ensuring sealing and welding function, reducing deformation and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

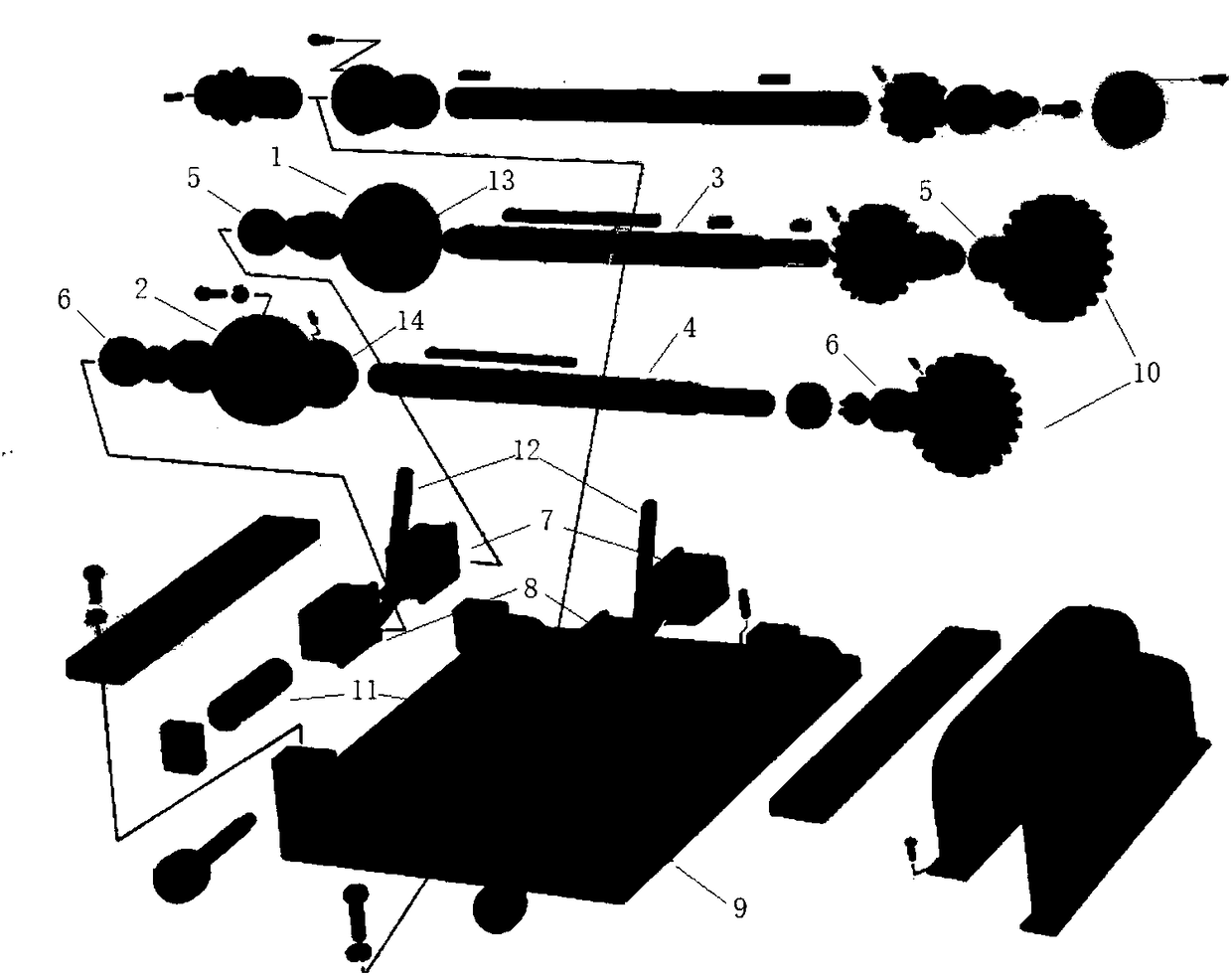

[0068] figure 1 It is an exploded schematic view showing a film conveying mechanism of an automatic vertical filling and packaging machine according to various embodiments of the present invention.

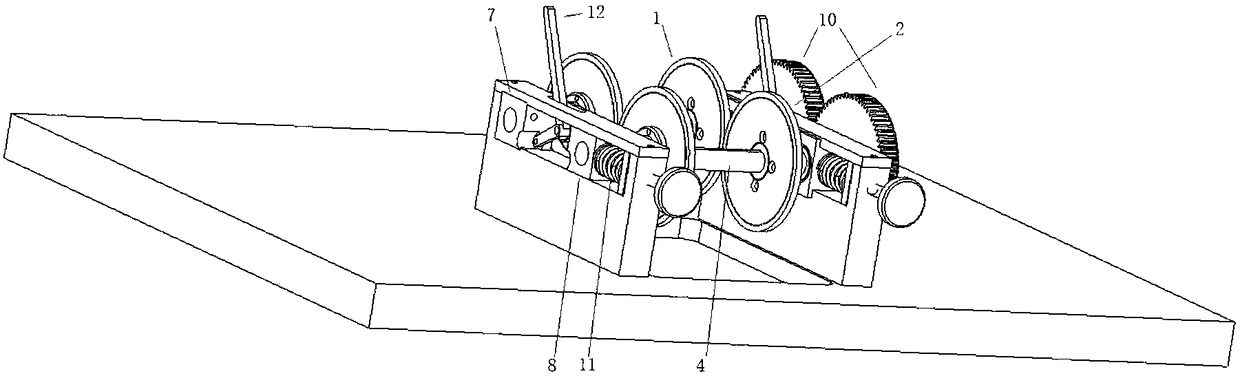

[0069] figure 2 is a perspective view illustrating a film conveying mechanism of an automatic vertical filling and packaging machine according to various embodiments of the present invention.

[0070] Such as figure 1 with figure 2 As shown in, the film conveying mechanism of the automatic vertical filling and packaging machine according to the present invention includes a pair of conveying wheels 1, 2, a stationary conveying wheel shaft 3, a movable conveying wheel shaft 4, a stationary bearing seat 7, a movable bearing seat 8, a support 9 and Leverage12.

[0071] A pair of conveying wheels 1 and 2 are respectively installed in the middle of the stationary conveying axle 3 and the movable conveying axle 4 through flange bushings 13 and 14, and the flange bushings 13 and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com