Open mill applied to processing of regenerated rubber

A technology of regenerated rubber and open mill, which is applied in the field of rubber plastication, which can solve the problems of low adjustment efficiency, material mixing, and difficulty in ensuring the same adjustment amount of the adjusting screw.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

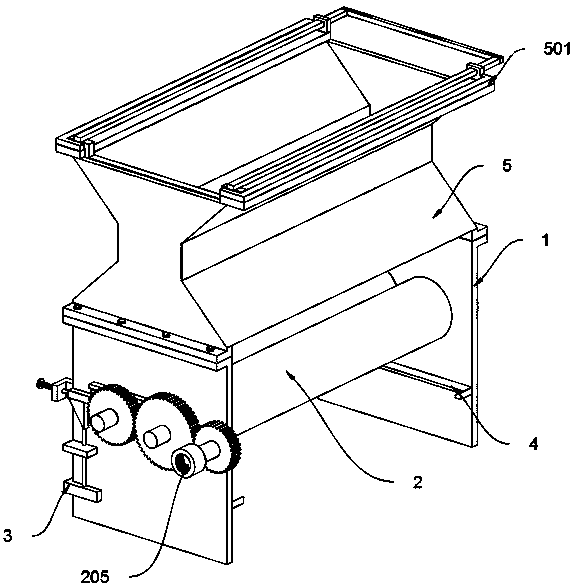

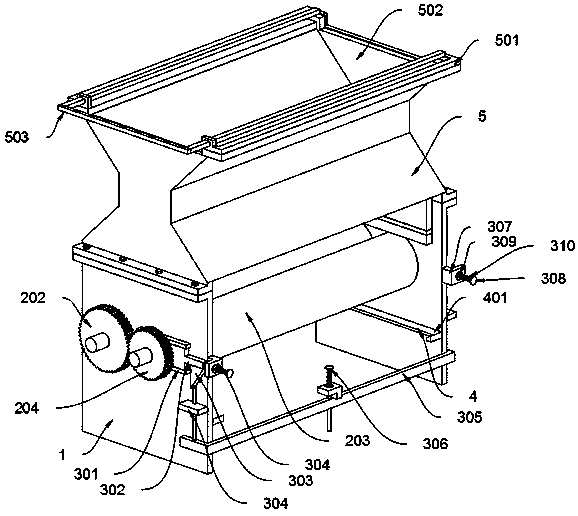

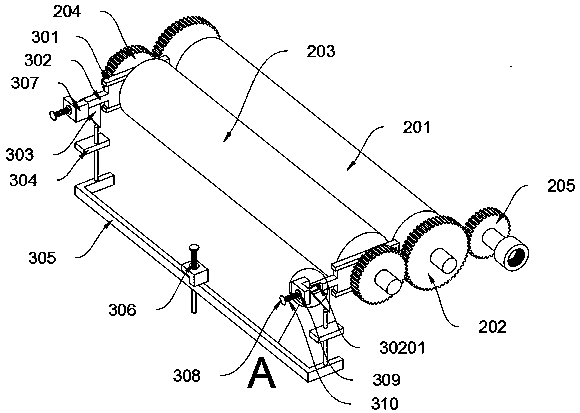

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides an open mill for processing recycled rubber, comprising a frame body 1; a processing structure 2 is rotatably connected to the frame body 1, and an adjustment structure 3 is installed on the frame body 1; refer to for example image 3, the adjustment structure 3 includes a sliding seat 301, a roller seat 302, a limit sliding groove 30201, an adjustment block 303, a limit sliding seat 304, a jacking adjustment frame 305 and an adjustment rod 306; the sliding seat 301 on the adjustment structure 3 is co-located There are two, and two sliding seats 301 are respectively welded on the left and right sides of the frame body 1; each sliding seat 301 is elastically slidably connected with a roller seat 302, and the rotating shaft of the moving roller 203 is rotatably connected to two On the roller seat 302; each roller seat 302 is provided with a limiting sliding groove 30201, and each roller seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com