Temper mill outlet condensate water collecting device and using method thereof

A technology of collecting device and leveling machine, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of water droplets being blown clean by compressed air, and achieve the effect of simple structure, convenient use and improvement of leveling quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

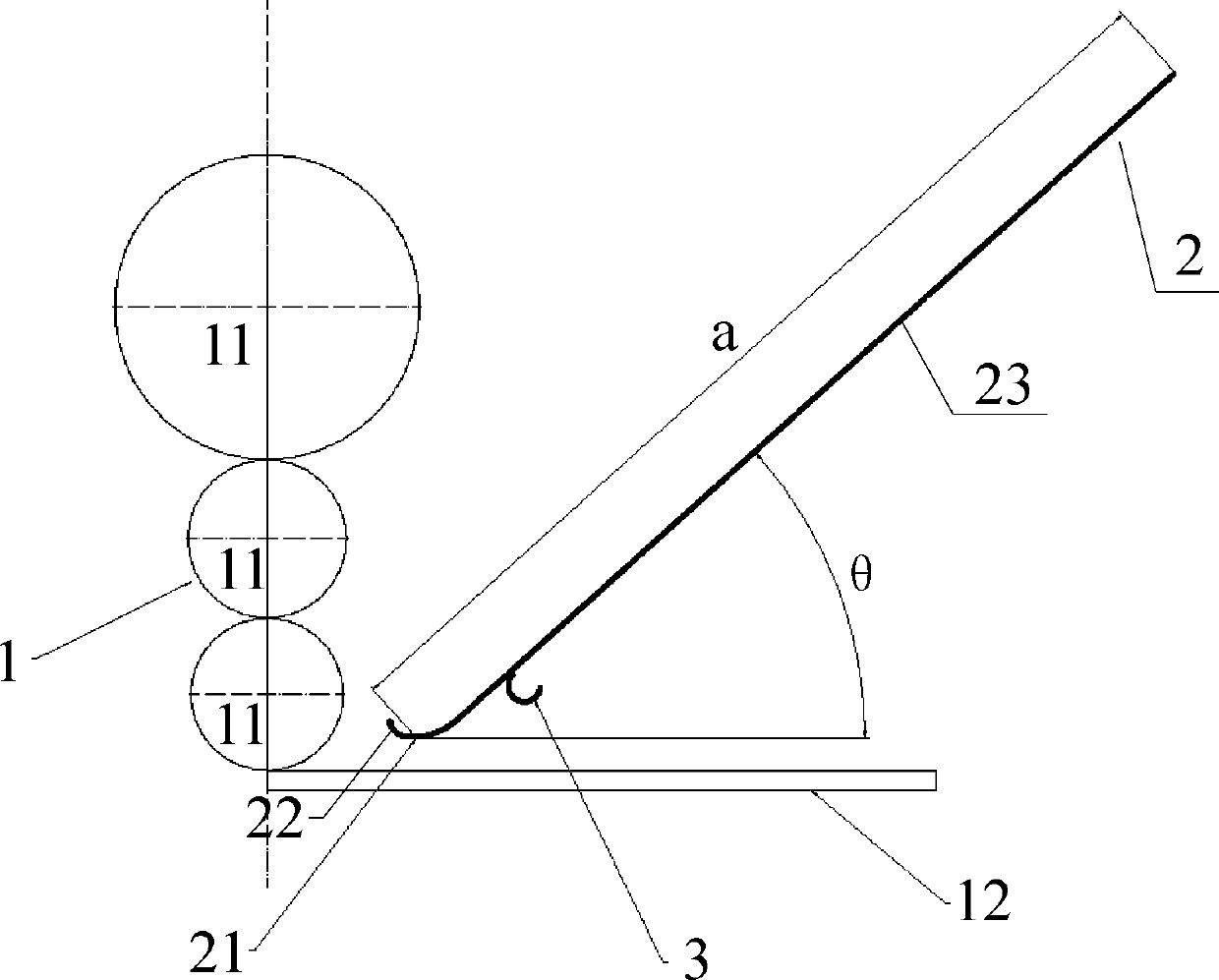

[0019] A condensed water collection device at the exit of a temper mill, comprising a temper mill 1, a main manifold 2 and a branch manifold 3, such as figure 1 As shown, the specific structure is:

[0020] The tempering machine 1 includes a roll set 11, and the metal plate 12 to be leveled is output after being rolled and leveled by the roll set 11,

[0021] The main manifold 2 includes a horizontal plate 21, a baffle 22 and an inclined plate 23, one side of the horizontal plate 21 is connected to one side of the baffle 22, the baffle 22 and the horizontal plate 21 are oblique to each other, and the other side of the horizontal plate 21 One side of the sloping plate 23 is connected, and the other side of the sloping plate 23 extends upwards and forms an obtuse angle with the horizontal plate 21; the horizontal plate 21 and the sloping plate 23 are both arranged above the exit end of the tempering machine 1;

[0022] The branch flow tank 3 is a groove, and one side of the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com