Steel pipe inner and outer plastic dipping production system

A production system, the technology of the inner wall of steel pipes, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problems of high price, expensive process equipment, thin coating, etc., to solve the problem of "three wastes", The effect of less environmental pollution and shorter construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] It will be understood that when a component is referred to as being "connected" to another component, it can be directly connected to the other component or intervening components may be present. Parts not described in detail in the present invention belong to common knowledge of those skilled in the art.

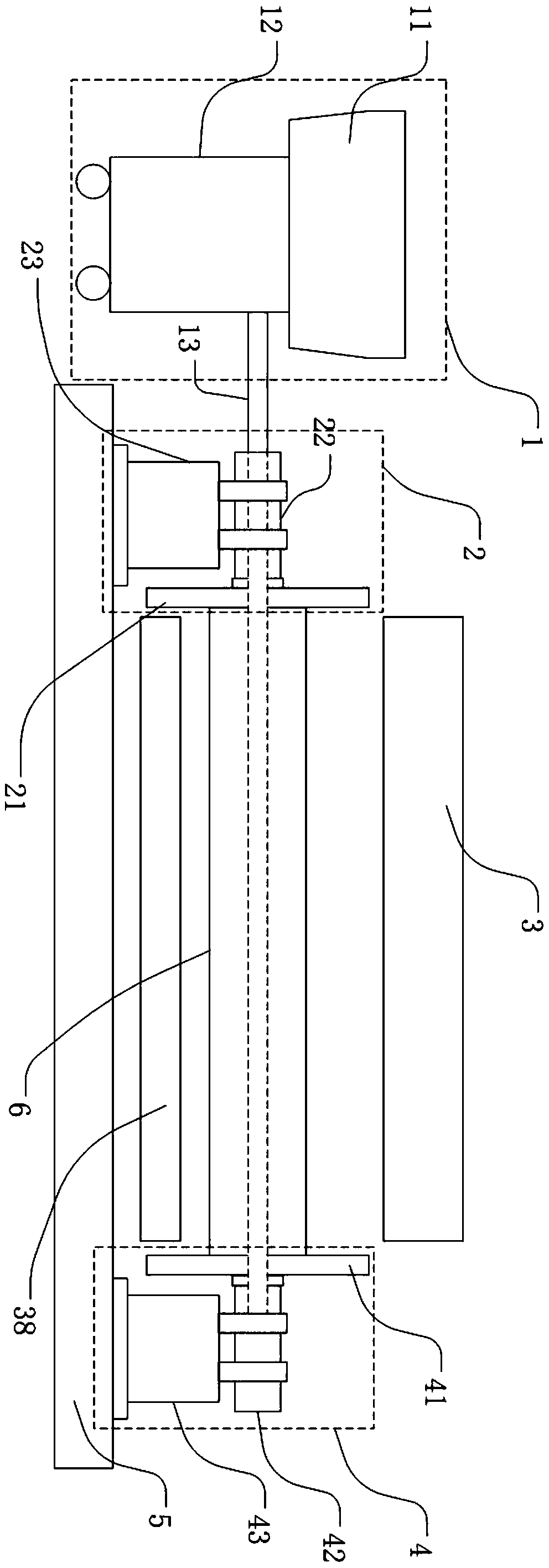

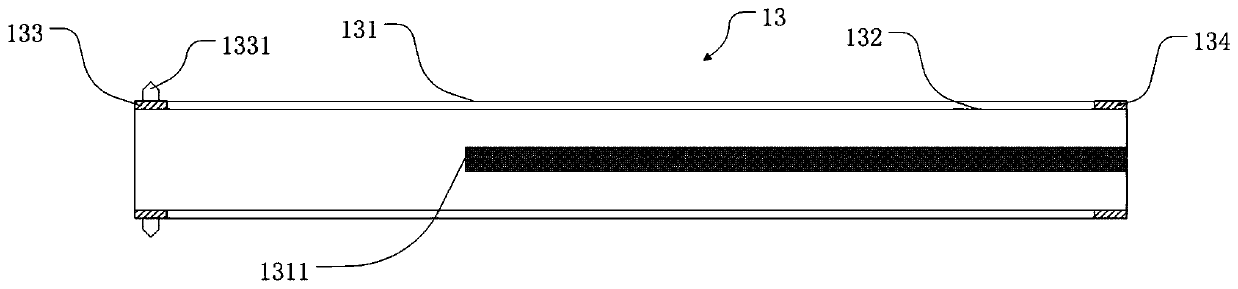

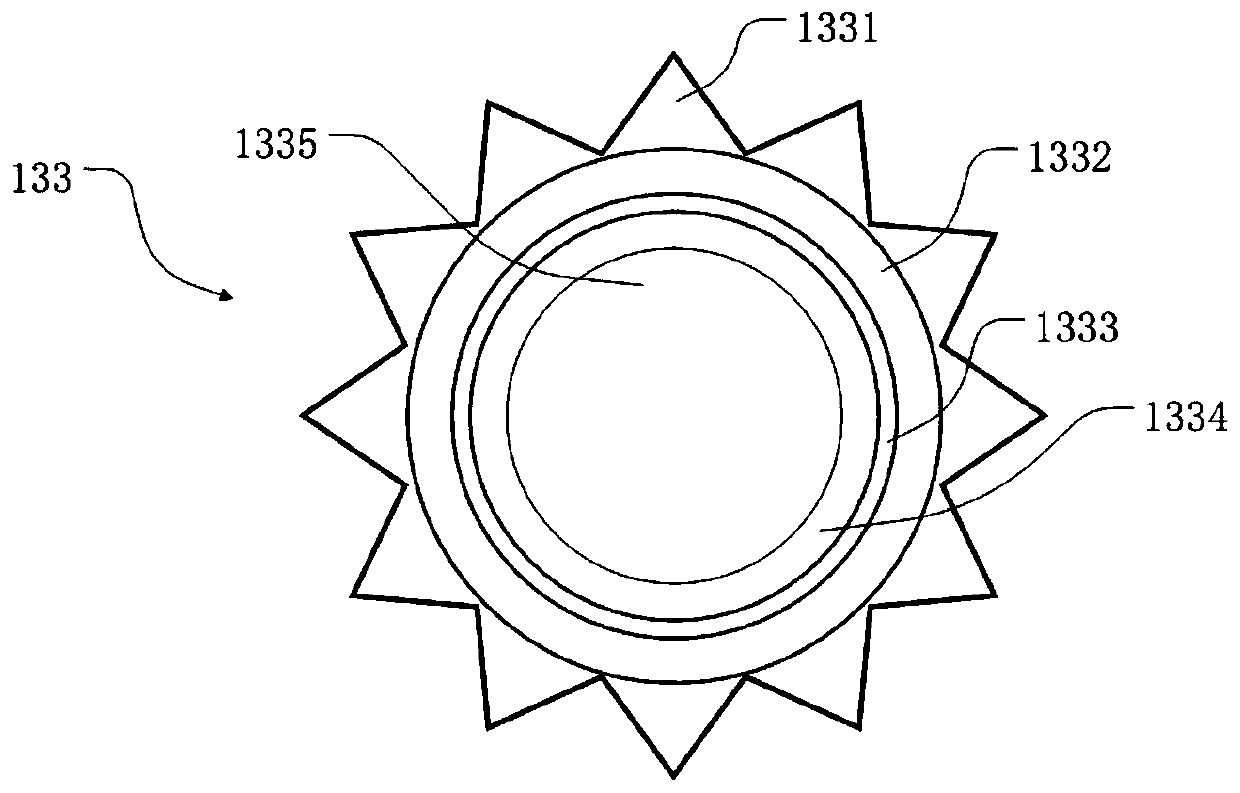

[0016] like figure 1 As shown, the steel pipe inner and outer plastic dipping production system of the present invention includes a steel pipe inner wall feeding device 1 , a first steel pipe fixing device 2 , a steel pipe outer wall feeding device 3 , a second steel pipe fixing device 4 , and a base 5 . Wherein the first steel pipe fixing device 2 and the second steel pipe fixing device 4 are respectively arranged at two opposite ends of the base 5 . The first steel pipe fixing device 2 and the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com