Versatile horizontal rake for plant protection

A multi-functional, hay rake technology, applied in the field of hay rakes, can solve the problems of dirt and grass being entangled between the shafts of the moving wheels, inconvenient adjustment of the rake hook distance, inconvenient connection and reinforcement, etc., to increase the cleaning function, Increase the effect of adjusting function and strengthening connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

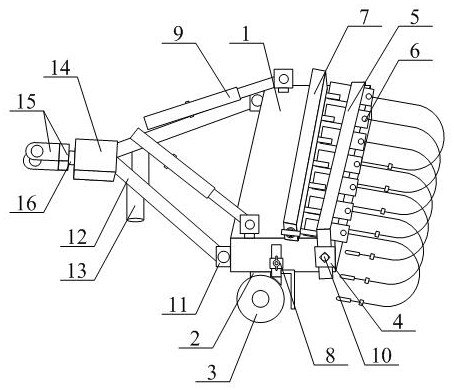

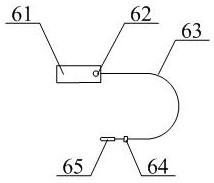

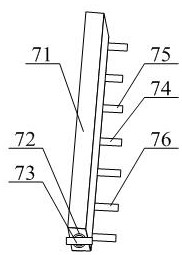

[0033] The present invention will be specifically described in conjunction with the accompanying drawings. figure 1 Attach figure 2, The multifunction plant protection use lateral tedder, comprising a rake bracket, the first connecting rod 2, moving wheels 3, a first fixed pipe 4, the pressure rod cover 5, the rotatable hook rake structure 6 may be adjusted a fixed box structure 7, cleaning may be fixed guard bar structure 8, the telescopic rotating pole reinforcing structure 9, the head bolt 10, U-type connector housing 11, the second connecting rod 12, support rod 13, a first connecting seat 14, U-type connecting frame 15 and the third connecting rod 16, the upper end of said first connecting rod 2 are welded to the lower end of the rake frame 1 on the front left and rear left lower position; moving said wheel shaft 3 are connected to the first 2 a lower portion of the front surface and the rear surface of a lower position of a connecting rod; said first fixed pipe 4 are welded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com