Substrate drying method and substrate drying device

一种干燥方法、干燥装置的技术,应用在干燥气体布置、干燥固体物料、非渐进式干燥机等方向,能够解决图案倒塌等问题,达到防止图案倒塌、防止衬底结露的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

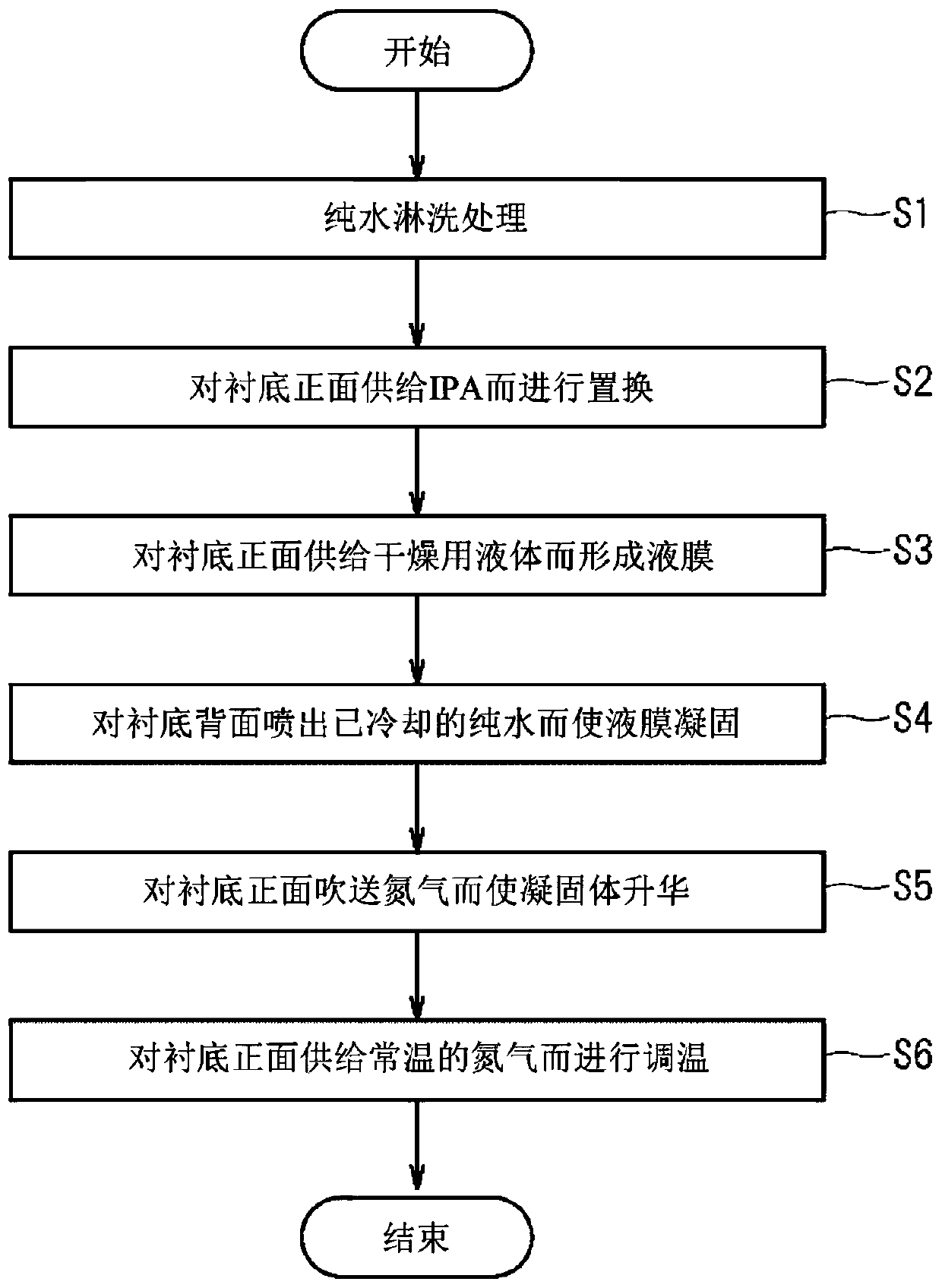

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

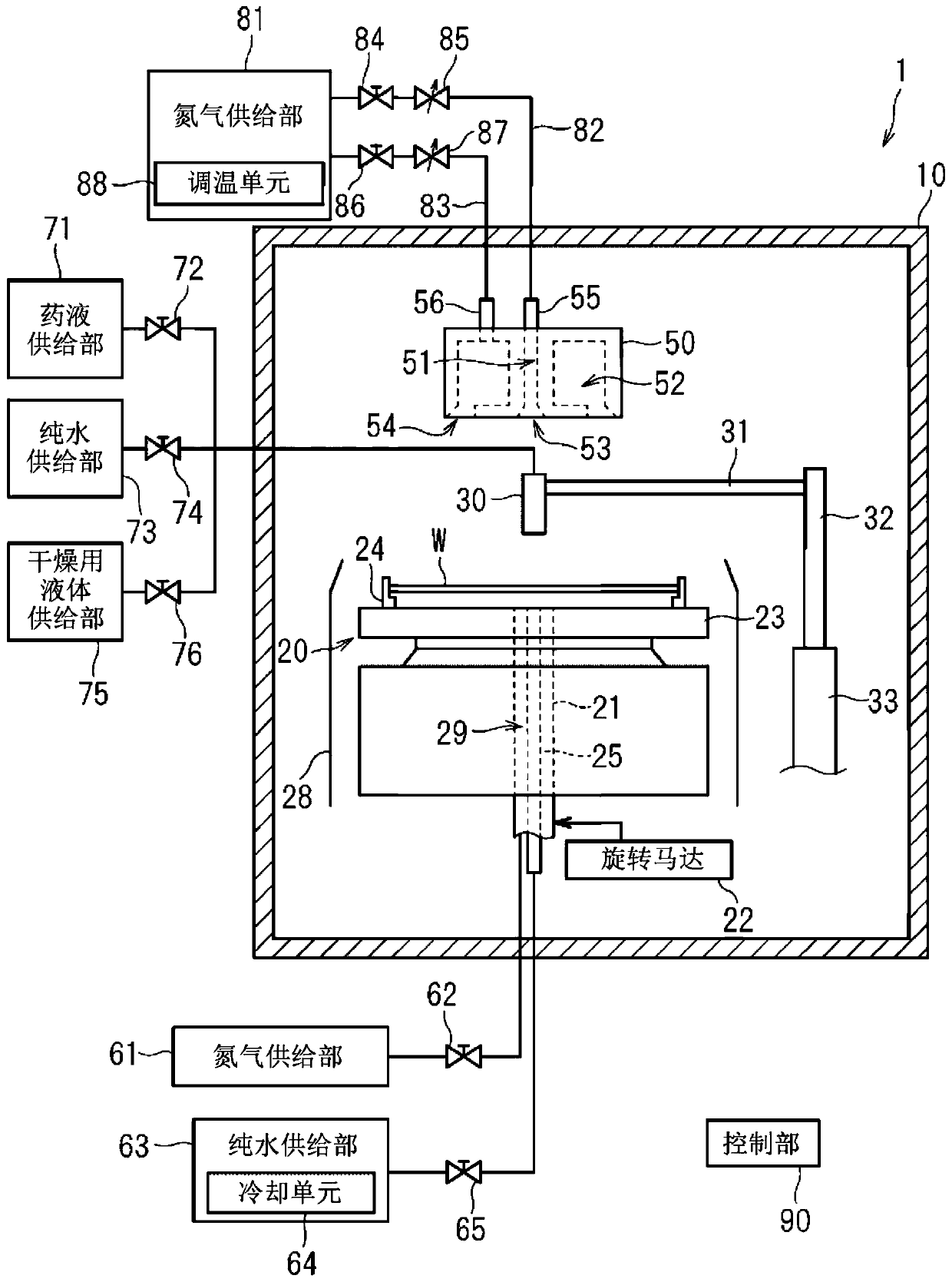

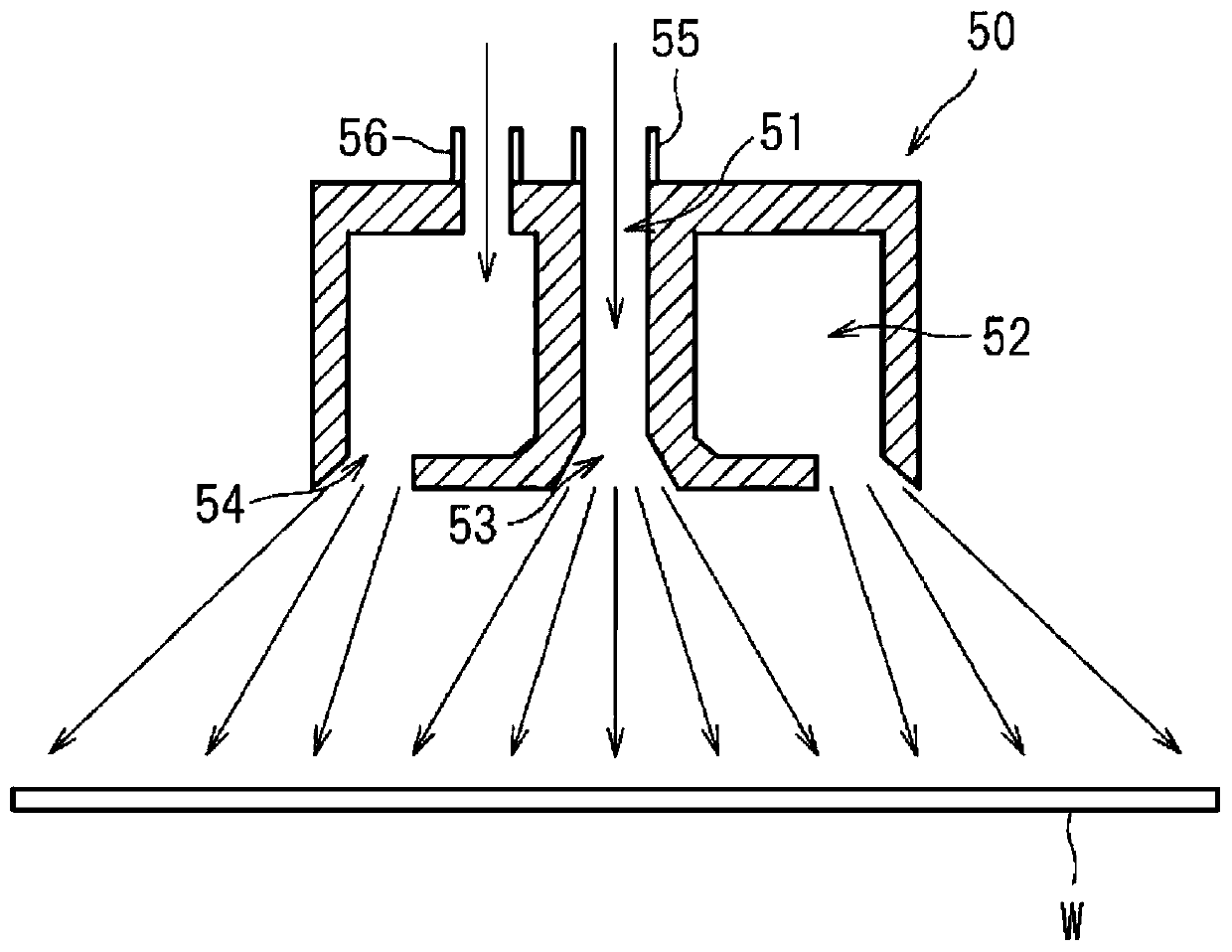

[0037] figure 1 It is a figure which shows the whole main part structure of the substrate drying apparatus of this invention. The substrate drying apparatus 1 is an apparatus for performing various liquid treatments on the front surface of a disk-shaped substrate W such as a semiconductor wafer, and drying the liquid adhering to the front surface of the substrate W after the liquid treatment by removing the liquid. The size of the substrate W to be processed is not particularly limited, but is, for example, φ300 mm or φ450 mm (in this embodiment, φ300 mm). Furthermore, in figure 1 In the subsequent drawings, the size and number of each part are exaggerated or simplified as necessary for easy understanding.

[0038] The substrate drying apparatus 1 includes a chamber 10 having a processing space inside which accommodates the substrate W and perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com