Natural creamer with high tolerance to acidity and minerals in beverage

A technology of creamer and protein, applied in the field of creamer of food products such as coffee and tea, to achieve smooth texture, no odor, excellent whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] The following examples illustrate various embodiments of the present disclosure by way of illustration and not limitation.

[0098] The liquid creamer was prepared as follows. The method passes through the method flowchart ( Figure 5 a) Demo.

[0099] A dry blend of sugar, sodium bicarbonate, high acyl gellan gum, guar gum, yellow pea protein, sea salt, natural flavors was prepared by combining 27,000 g of sucrose with 300 g of sodium bicarbonate, 100 g of high acyl gellan Gum, 100g guar gum, 500g pea protein, 100g sea salt, 111g natural flavoring. The dry blend was added to 50 kg of hot water (approximately 75°C) under high agitation.

[0100] Next, and after 5 minutes of mixing under continuous high agitation, 4.5 kg of almond pulp was added to the tank over 5 minutes under high agitation.

[0101] Next, and after 5 minutes of mixing under continuous high agitation, 3.0 kg of coconut oil was added to the tank over 5 minutes under high agitation. Additional water...

Embodiment 2

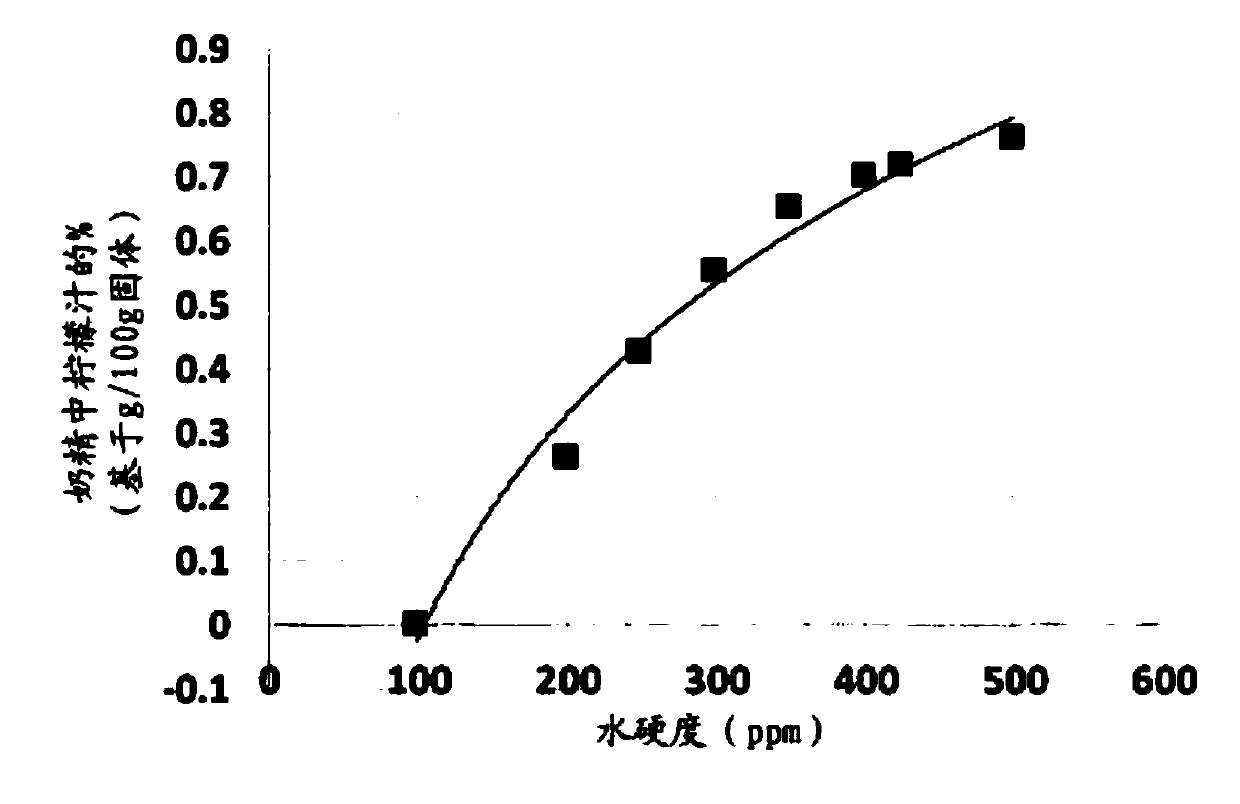

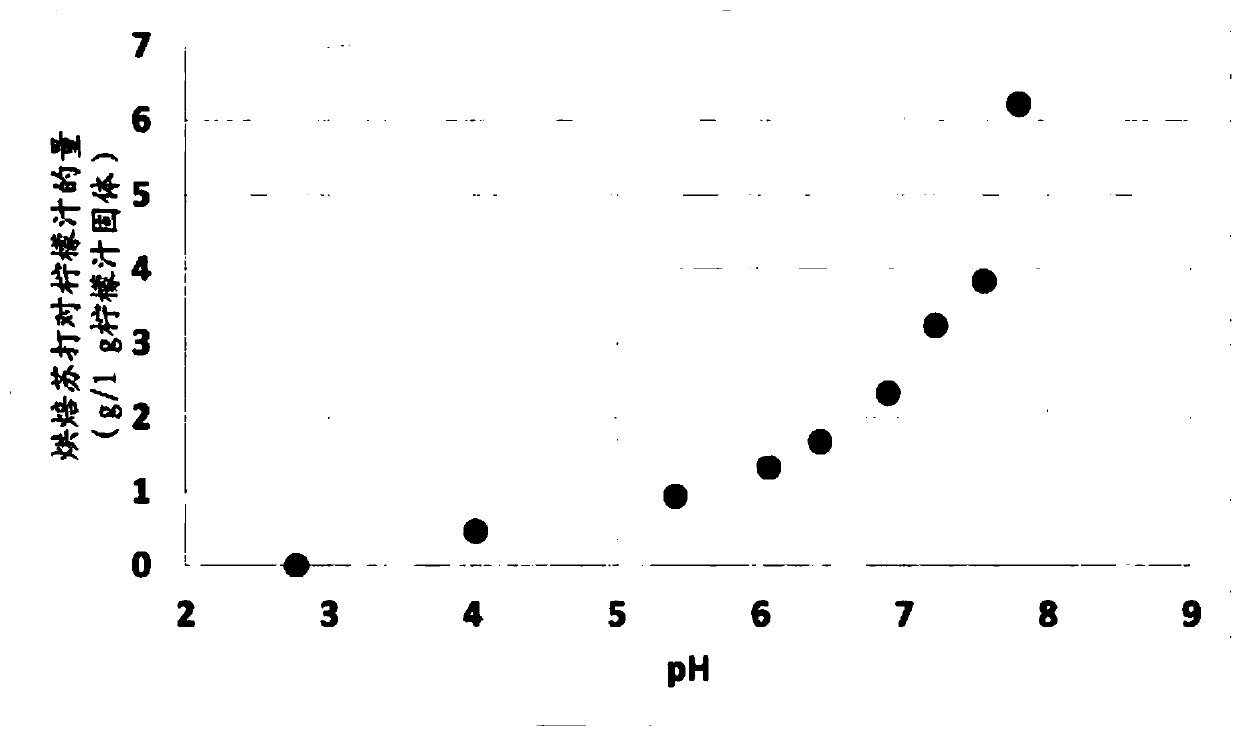

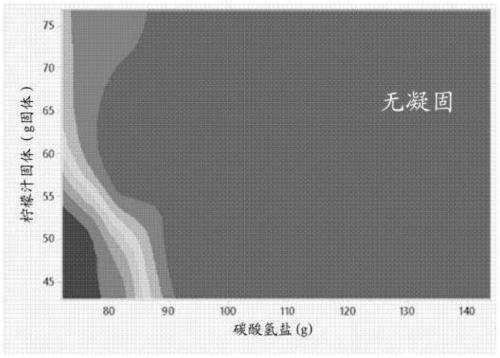

[0107] A liquid creamer was prepared as in Example 1 but using 800g of baking soda and 1.2kg of lemon juice concentrate 400GPL. Baking soda was added to 50 kg of hot water (approximately 75° C.) under high agitation within 5 minutes before dispersing the dry mix as cited in Example 1, and then lemon juice concentrate 400 GPL was added and mixed for 5 minutes. minute. The method passes through the method flowchart ( Figure 5 b) Demonstration. The physicochemical stability and organoleptic properties of the creamer and coffee beverages with added liquid creamer were judged by trained panelists. No phase separation (creaming, deoiling, marbling, etc.), gelation, and almost no viscosity change was observed during storage. It was surprisingly found that liquid creamer does not coagulate or flocculate when added to 100% Arabica coffee (e.g., 100% medium roast Colombian coffee) brewed with water hardness above 240ppm, as Figure 6 Shown in B.

Embodiment 3

[0109] A dry blend of sugar, sodium bicarbonate, high acyl gellan gum, and yellow pea protein was prepared by mixing together 27,000 g sucrose with 250 g sodium bicarbonate, 90 g high acyl gellan gum, and 500 g pea protein. The dry blend was added to 50 kg of hot water (approximately 75°C) under high agitation.

[0110] Next, and after 5 minutes of mixing under continuous high agitation, 17 kg of coconut (in the form of cream) was added to the tank under high agitation. After 5 minutes, 3.0 kg of coconut oil was added and mixed for 5 minutes. Additional water was added to adjust the total to 100 kg.

[0111] The liquid creamer was pre-homogenized at 130 / 30, pre-heated, UHT-treated at 136°C for 12 seconds, homogenized at 130 / 30 bar and cooled. Liquid creamer is aseptically filled into bottles. The resulting liquid creamer can be aseptically filled into any sterile container such as eg jars, jugs or bags. Liquid creamers were stored at 4°C for 5 months.

[0112] The physico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com