Preparation method and application of biomass carbon/Ga2O3 composite material

A composite material, biomass carbon technology, applied in the field of electrochemical power supply, can solve the problems of low conductivity, poor electrochemical reaction kinetics, unsatisfactory cycle performance, etc., and achieves low cost, wide biomass sources, and good cycle. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

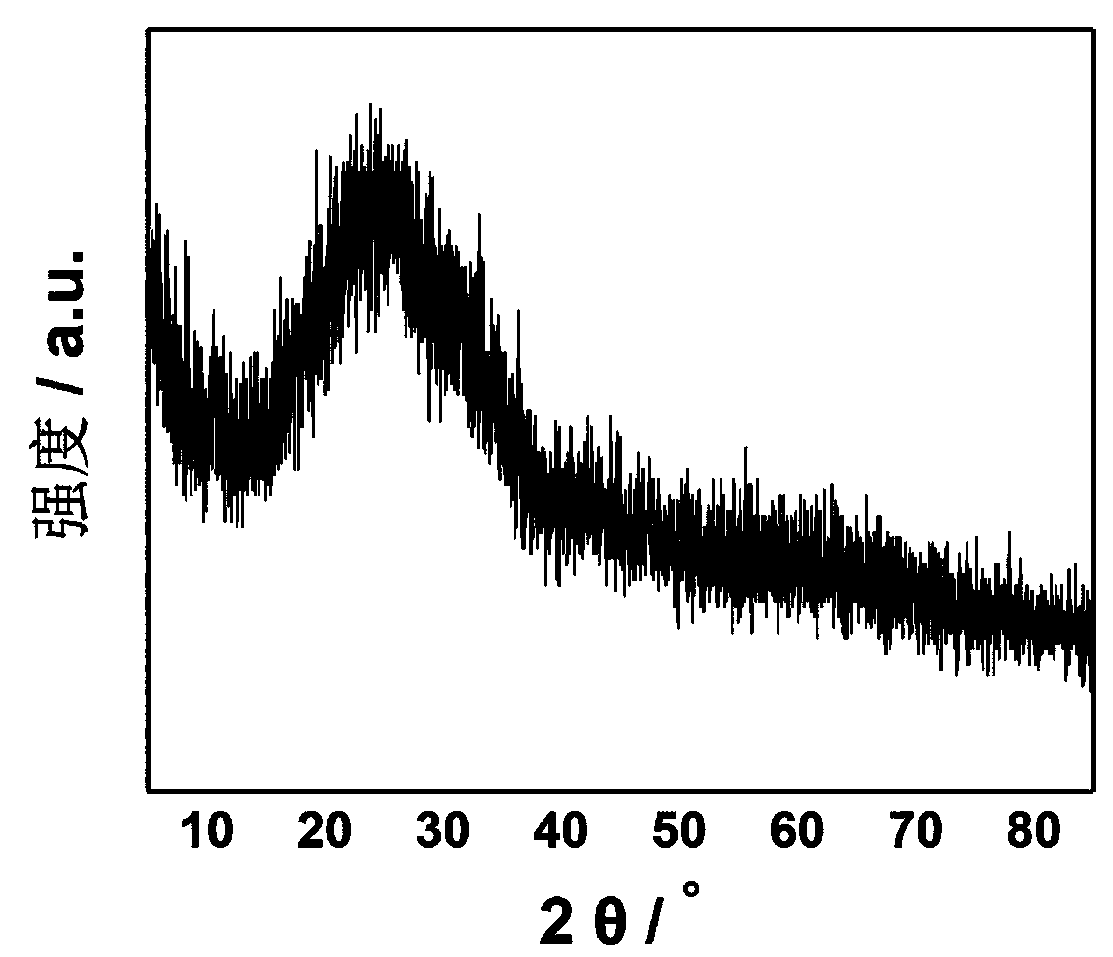

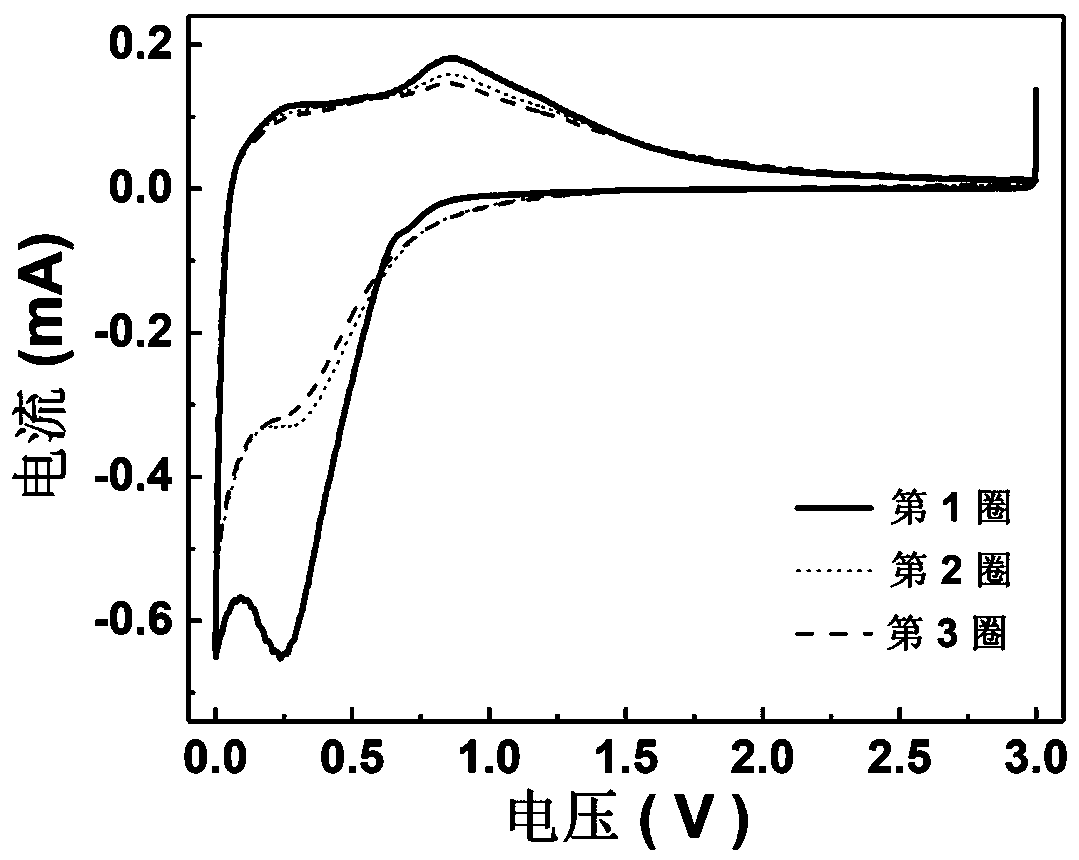

[0026] Cattail ears (such as figure 1 ) in sodium hydroxide solution for 2 hours, then cleaned with deionized water, and then transferred to a blast drying oven at 80°C for drying; take 2mL of nitric acid and add 8mL of deionized water, stir well and add 1mmolGa(NO 3 ) 3 ·xH 2 0, then add 1.2g of treated cattail ears to the solution, ultrasonically treat it for 2h, and then transfer it to 80°C blast drying oven for drying; after the material is dried, it is placed in N 2 In the environment, at a heating rate of 3°C / min, calcined at 500°C for 5h to obtain biomass carbon / Ga 2 o 3 composite material. The prepared samples were analyzed by XRD patterns as follows: figure 2 As shown, there is a broad diffraction peak at 25°, corresponding to amorphous C, due to Ga 2 o 3 Poor crystallinity, no Ga in the picture 2 o 3 Diffraction peaks. like image 3 For the prepared biomass carbon / Ga 2 o 3 Cyclic voltammetry curves of the composite lithium-ion battery negative electrode...

Embodiment 2

[0029] Cattail ears (such as figure 1 ) in sodium hydroxide solution for 2 hours, then cleaned with deionized water, and then transferred to a blast drying oven at 80°C for drying; take 2mL of nitric acid and add 8mL of deionized water, stir well and add 1mmolGa(NO 3 ) 3 ·xH 2 0, then add 1.2g of treated cattail ears to the solution, ultrasonically treat it for 2h, and then transfer it to 80°C blast drying oven for drying; after the material is dried, it is placed in N 2 In the environment, at a heating rate of 3°C / min, calcined at 600°C for 5h to obtain biomass carbon / Ga 2 o 3 composite material.

[0030] The material obtained in Example 2 was made into a battery according to the method in Example 1. like Figure 6 As shown, the first charge and discharge specific capacities are 482.7 and 966.6mAh g respectively -1 , there is an obvious charging and discharging platform, and after 50 cycles, the charging and discharging capacities are 437.7 and 439.6mAh g respectively ...

Embodiment 3

[0032] Cattail ears (such as figure 1 ) in sodium hydroxide solution for 2 hours, then cleaned with deionized water, and then transferred to a blast drying oven at 80°C for drying; take 2mL of nitric acid and add 8mL of deionized water, stir well and add 1mmolGa(NO 3 ) 3 ·xH 2 0, then add 1.2g of treated cattail ears to the solution, ultrasonically treat it for 2h, and then transfer it to 80°C blast drying oven for drying; after the material is dried, it is placed in N 2 In the environment, at a heating rate of 3°C / min, calcined at 700°C for 5h to obtain biomass carbon / Ga 2 o 3 composite material.

[0033] The material obtained in Example 3 was made into a battery according to the method in Example 1. like Figure 7 As shown, the first charge and discharge specific capacities are 497.4 and 991.0mAh g respectively -1 , with obvious charge and discharge platforms, after 50 cycles, the charge and discharge capacities are 447.6 and 448.7mAh g respectively -1 , showing good...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com