Method for sequentially drying walnuts through drum-type constant-temperature infrared rays and hot air

A hot air drying and drum-type technology, which is applied in the direction of non-progressive dryers, biomass drying, drying solid materials, etc., to achieve the effect of shortening the drying time, simple equipment, and efficient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

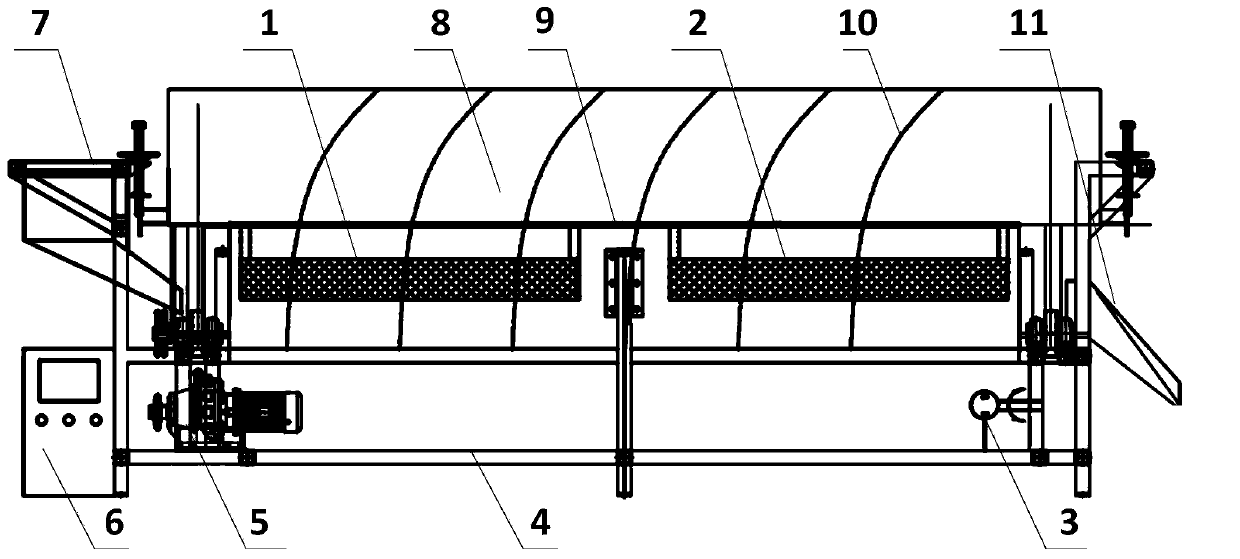

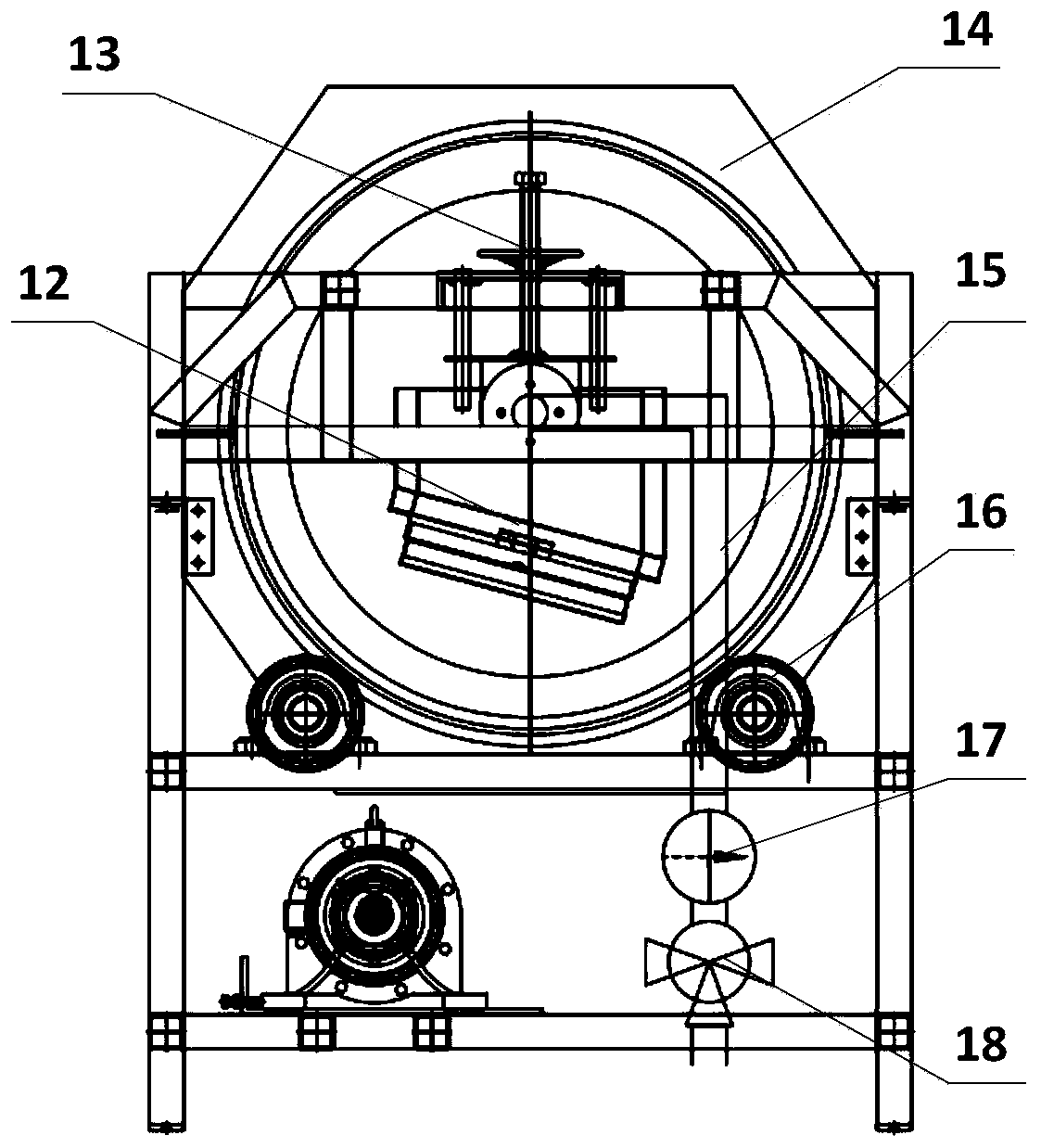

[0027] Embodiment 1: drum type constant temperature infrared pre-drying

[0028] The drum type constant temperature infrared pre-drying method of fresh walnuts is carried out according to the following steps:

[0029] (1) Remove the outer layer of green skin from the picked fresh walnuts, rinse them with clean water, and drain the surface moisture;

[0030] (2) Adjust the infrared radiation distance to 25cm. Adjust the infrared radiation temperature of catalytic infrared generators 1 and 2 to 450 °C. Adjust the rotation speed of the drum to 35Hz. Then pour the fresh walnuts into the feeding hopper, stop the infrared pre-drying after the walnuts come out of the discharge port, and obtain the infrared pre-dried walnuts;

[0031] (3) Determination of moisture content decline rate, chromaticity change value and shell opening rate of samples: take 20 walnuts and record the initial dry basis moisture content WC of samples respectively 0 and surface chromaticity ΔE 0 , and then ...

Embodiment 2

[0036] The test treatment process is the same as in Example 1, the difference being that the infrared radiation distance is 30 cm, and the specific results are shown in Table 1.

Embodiment 3

[0038] The test treatment process is the same as in Example 1, the difference being that the infrared radiation distance is 35 cm, and the specific results are shown in Table 1.

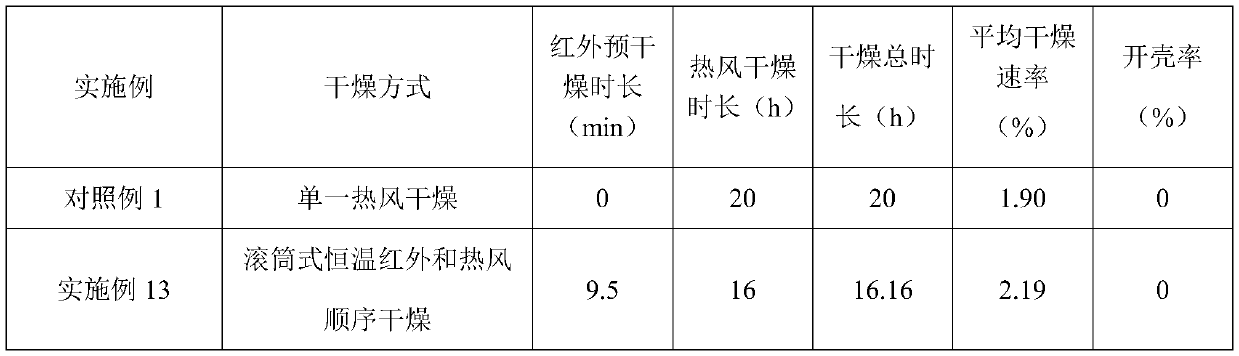

[0039] Table 1 Effects of different infrared radiation distances on moisture content drop rate, chromaticity change value and shell opening rate

[0040] Example Radiation distance (cm) Moisture content drop rate (%) Chromaticity change value Shell opening rate (%) Remark Example 1 25 7.724±1.410 12.427±2.854 0 small area tan Example 2 30 7.267±0.631 8.403±1.561 0 none Example 3 35 7.046±0.881 8.474±2.083 0 none

[0041]It can be found that the moisture content reduction rate of samples of comparative examples 1-3 in Table 1, the moisture content reduction rate on a dry basis of walnuts decreases with the increase of the board distance, and the board distance of 25 cm is better than the board distance of 30 cm and better than the board distance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com