A kind of preparation method of hot and humid comfortable fabric

A comfortable and fabric technology, applied in the field of preparation of heat-moisture comfortable fabrics, can solve the problems of increased friction of cellulose fibers, easy to fail, limited efficiency, etc., and achieve the effects of simple process, excellent comprehensive performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

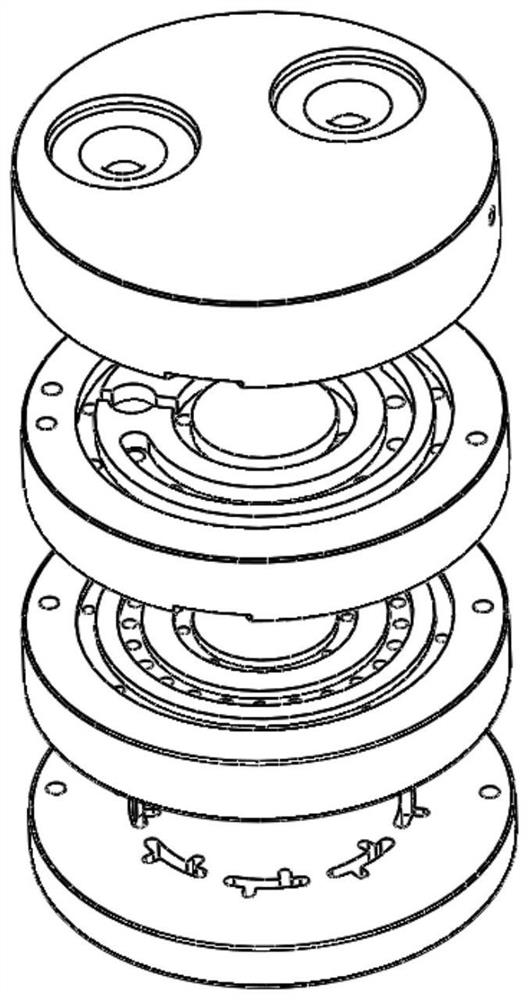

Image

Examples

Embodiment 1

[0048] A preparation method of a heat-moisture comfortable fabric, the steps are as follows:

[0049] (1) Preparation of PET-PA6 copolymer:

[0050] After mixing PET with a number-average molecular weight of 2,000 and PA6 with a number-average molecular weight of 2,000 in a mass ratio of 1:1, the polycondensation reaction was carried out for 40 minutes at a temperature of 273° C. and a vacuum degree of 46.9 Pa;

[0051] (2) Preparation of special-shaped fibers:

[0052] According to the FDY process, the mass ratio of 55:45 PET melt (intrinsic viscosity of 0.58dL / g) and PA6 melt (intrinsic viscosity of 2.3dL / g) was dispensed from the spinneret holes on the same spinneret. After extruding the FDY filaments, relaxation heat treatment is performed to obtain special-shaped fibers; wherein, the PET melt and the PA6 melt each contain 5wt% of the PET-PA6 copolymer melt;

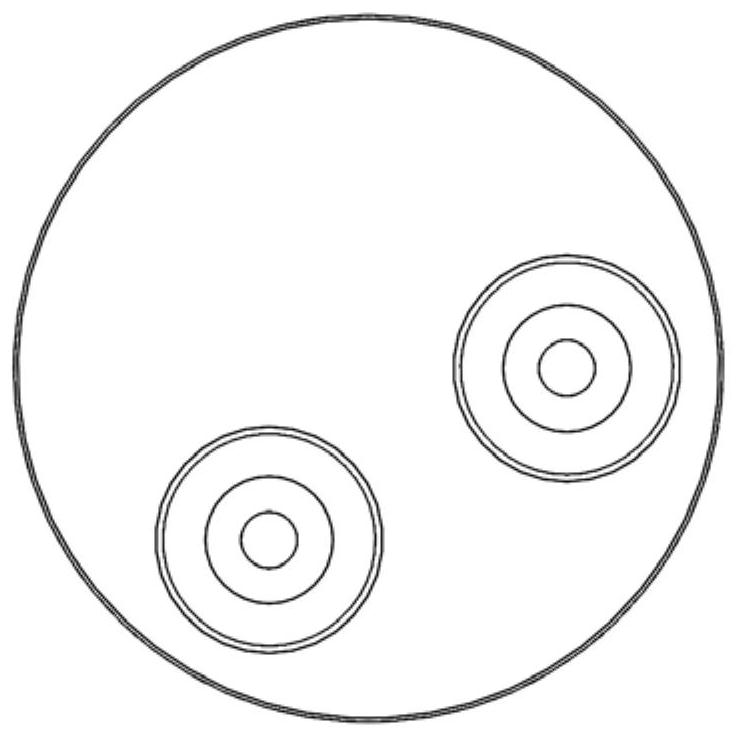

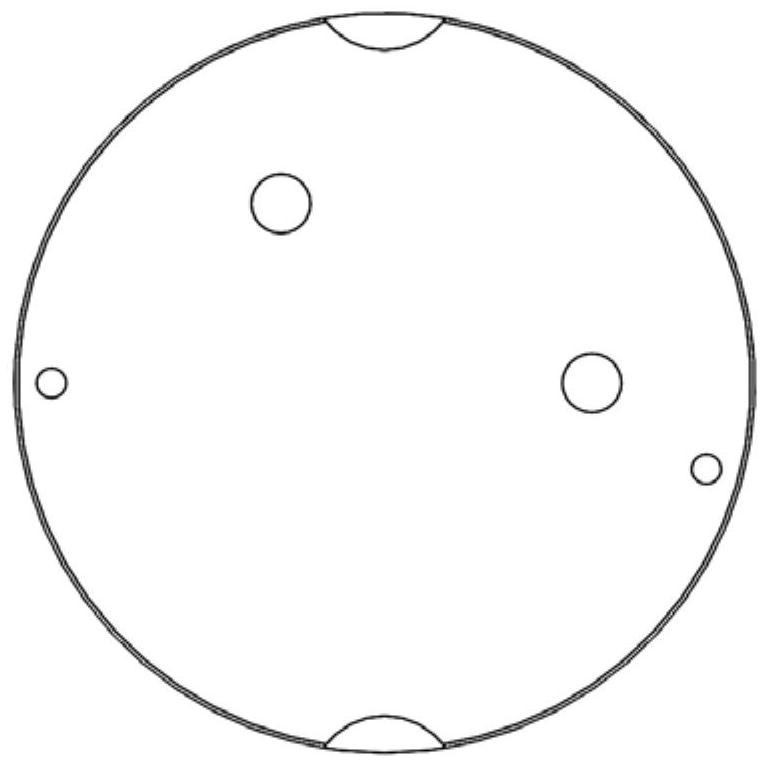

[0053] like Figure 8 As shown, the spinneret holes on the spinneret are shaped spinneret, The shape is com...

Embodiment 2

[0065] A preparation method of a heat-moisture comfortable fabric, the steps are as follows:

[0066] (1) Preparation of PET-PA6 copolymer:

[0067] After mixing PET with a number-average molecular weight of 2,600 and PA6 with a number-average molecular weight of 3,000 in a mass ratio of 1:1, the polycondensation reaction was carried out for 42 minutes at a temperature of 273 ° C and a vacuum of 47 Pa;

[0068] (2) Preparation of special-shaped fibers:

[0069] According to the FDY process, the mass ratio of 55:45 PET melt (intrinsic viscosity of 0.59dL / g) and PA6 melt (intrinsic viscosity of 2.4dL / g) was dispensed from the spinneret holes on the same spinneret. After extruding the FDY filaments, relaxation heat treatment is performed to obtain special-shaped fibers; wherein, the PET melt and the PA6 melt each contain 5wt% of the PET-PA6 copolymer melt;

[0070] The spinneret is shaped spinneret, The shape is composed of a horizontal line and vertical lines I and II vert...

Embodiment 3

[0082] A preparation method of a heat-moisture comfortable fabric, the steps are as follows:

[0083] (1) Preparation of PET-PA6 copolymer:

[0084] After mixing PET with a number-average molecular weight of 2200 and PA6 with a number-average molecular weight of 3000 at a mass ratio of 1:1, the polycondensation reaction was carried out for 51 min under the conditions of a temperature of 277° C. and a vacuum degree of 47.9 Pa;

[0085] (2) Preparation of special-shaped fibers:

[0086] According to the FDY process, PET melt (intrinsic viscosity: 0.62dL / g) and PA6 melt (intrinsic viscosity: 2.31dL / g) in a mass ratio of 60:40 were dispensed from the spinneret holes on the same spinneret. After extruding the FDY filaments, relaxation heat treatment is performed to obtain special-shaped fibers; wherein, the PET melt and the PA6 melt each contain 5wt% of the PET-PA6 copolymer melt;

[0087] The spinneret is shaped spinneret, The shape is composed of horizontal lines and vertic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com