Preparation method of moisture absorption and quick drying fabric

A hygroscopic and quick-drying fabric technology, applied in the field of fibers, can solve the problems of unsustainable overall hydrophobic effect, limited efficiency, and large moisture migration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for preparing a moisture-absorbing and quick-drying fabric, the steps are as follows:

[0050] (1) Preparation of PET-PA6 copolymer:

[0051] After mixing PET with a number average molecular weight of 2000 and PA6 with a number average molecular weight of 2000 at a mass ratio of 1:1, polycondensation reaction was carried out for 40 minutes at a temperature of 273 °C and a vacuum of 45.2 Pa to obtain a PET-PA6 copolymer thing;

[0052] (2) Preparation of shaped fibers:

[0053] According to the FDY process, after distributing PET melt (intrinsic viscosity 0.6dL / g) and PA6 melt (intrinsic viscosity 2.4dL / g) with a mass ratio of 55:45, from the spinneret holes on the same spinneret After the FDY filament is obtained by extrusion, relaxation heat treatment is carried out to obtain the shaped fiber; wherein, the PET melt and the PA6 melt each contain 5wt% of the PET-PA6 copolymer melt;

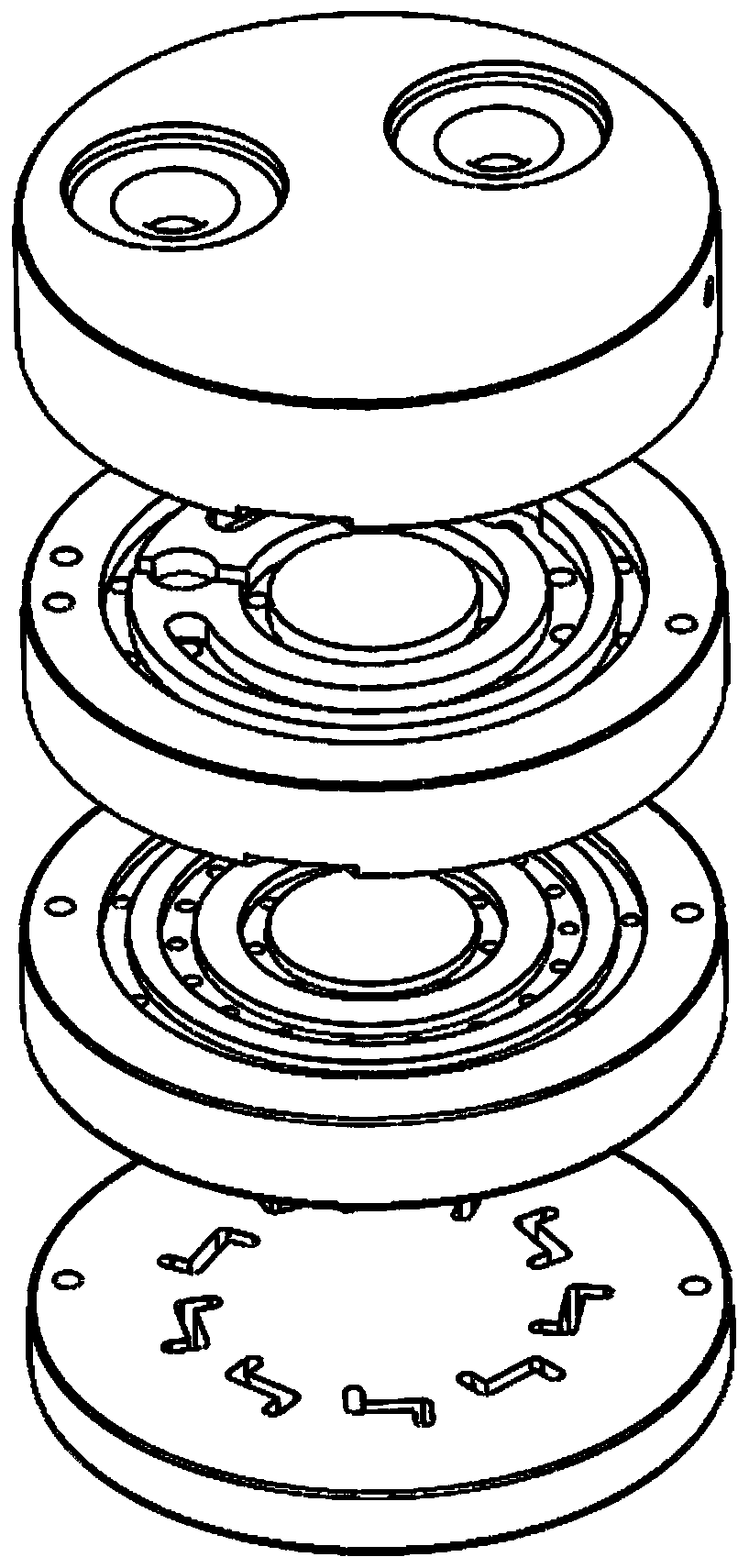

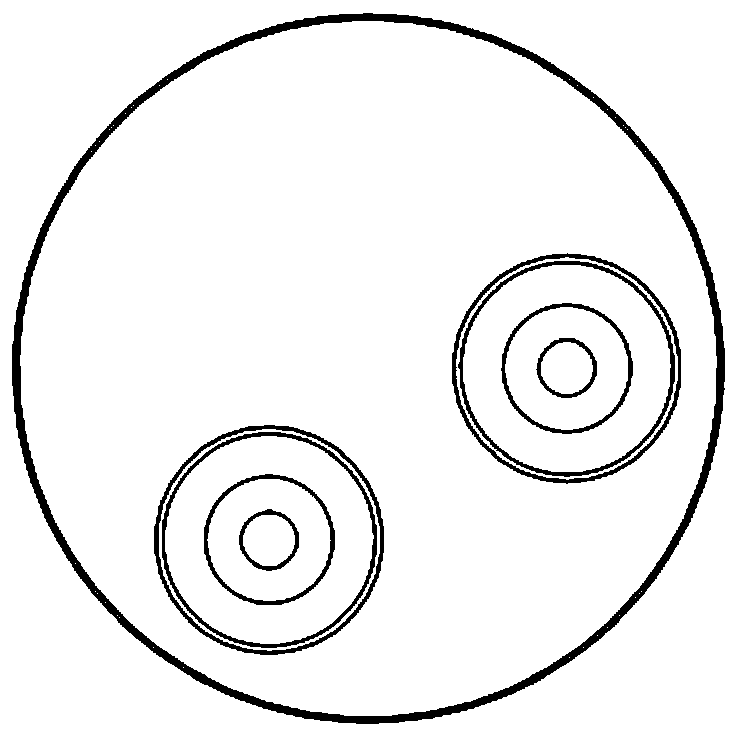

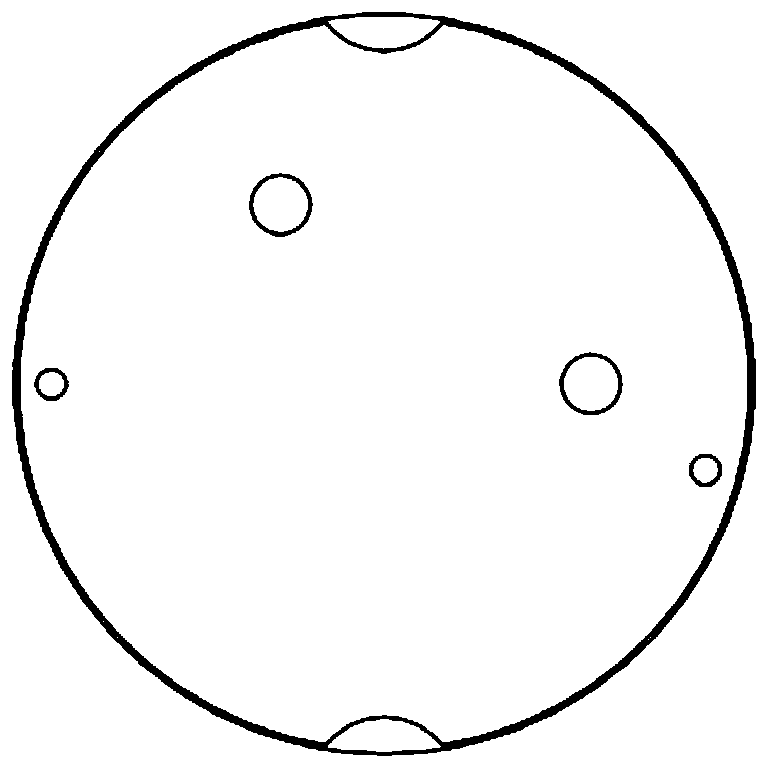

[0054] Such as Figure 8 As shown, the spinneret hole on the spinneret plat...

Embodiment 2

[0066] A method for preparing a moisture-absorbing and quick-drying fabric, the steps are as follows:

[0067] (1) Preparation of PET-PA6 copolymer:

[0068] After mixing PET with a number-average molecular weight of 3000 and PA6 with a number-average molecular weight of 2000 at a mass ratio of 1:1, the polycondensation reaction was carried out at a temperature of 274°C and a vacuum of 45.5Pa for 44 minutes to obtain a PET-PA6 copolymer thing;

[0069] (2) Preparation of shaped fibers:

[0070] According to the FDY process, after distributing PET melt (intrinsic viscosity 0.65dL / g) and PA6 melt (intrinsic viscosity 2.41dL / g) with a mass ratio of 65:35, from the spinneret holes on the same spinneret After the FDY filament is obtained by extrusion, relaxation heat treatment is carried out to obtain the shaped fiber; wherein, the PET melt and the PA6 melt each contain 5wt% of the PET-PA6 copolymer melt;

[0071] The spinneret hole is shaped spinneret hole, The shape is com...

Embodiment 3

[0083] A method for preparing a moisture-absorbing and quick-drying fabric, the steps are as follows:

[0084] (1) Preparation of PET-PA6 copolymer:

[0085] After mixing PET with a number-average molecular weight of 2800 and PA6 with a number-average molecular weight of 2300 at a mass ratio of 1:1, the polycondensation reaction was carried out at a temperature of 277°C and a vacuum of 46.1Pa for 54 minutes to obtain a PET-PA6 copolymer thing;

[0086] (2) Preparation of shaped fibers:

[0087] According to the FDY process, after distributing PET melt (intrinsic viscosity 0.65dL / g) and PA6 melt (intrinsic viscosity 2.46dL / g) with a mass ratio of 55:45, from the spinneret holes on the same spinneret After the FDY filament is obtained by extrusion, relaxation heat treatment is carried out to obtain the shaped fiber; wherein, the PET melt and the PA6 melt each contain 5wt% of the PET-PA6 copolymer melt;

[0088] The spinneret hole is shaped spinneret hole, The shape is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com