Preparation method of knitted fabric

A technology of knitted fabric and special-shaped fiber, which is applied in the field of fiber, can solve the problems of increased friction of cellulose fiber, poor wearing experience, and inability to arrive quickly, and achieve the effect of improving the ability to export moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A kind of preparation method of knitted cloth, its steps are as follows:

[0049] (1) The preparation process of shaped fiber is as follows:

[0050] According to the FDY process, using the composite spinning assembly located in the assembly spinning box, PET melt (intrinsic viscosity is 0.58dL / g) and PTT melt (intrinsic viscosity is 1.19dL / g) with a mass ratio of 40:60 ) after distribution, after extruding from the spinneret holes on the same spinneret to obtain FDY filaments, perform a relaxation heat treatment at a temperature of 112°C for 24 minutes to obtain special-shaped fibers;

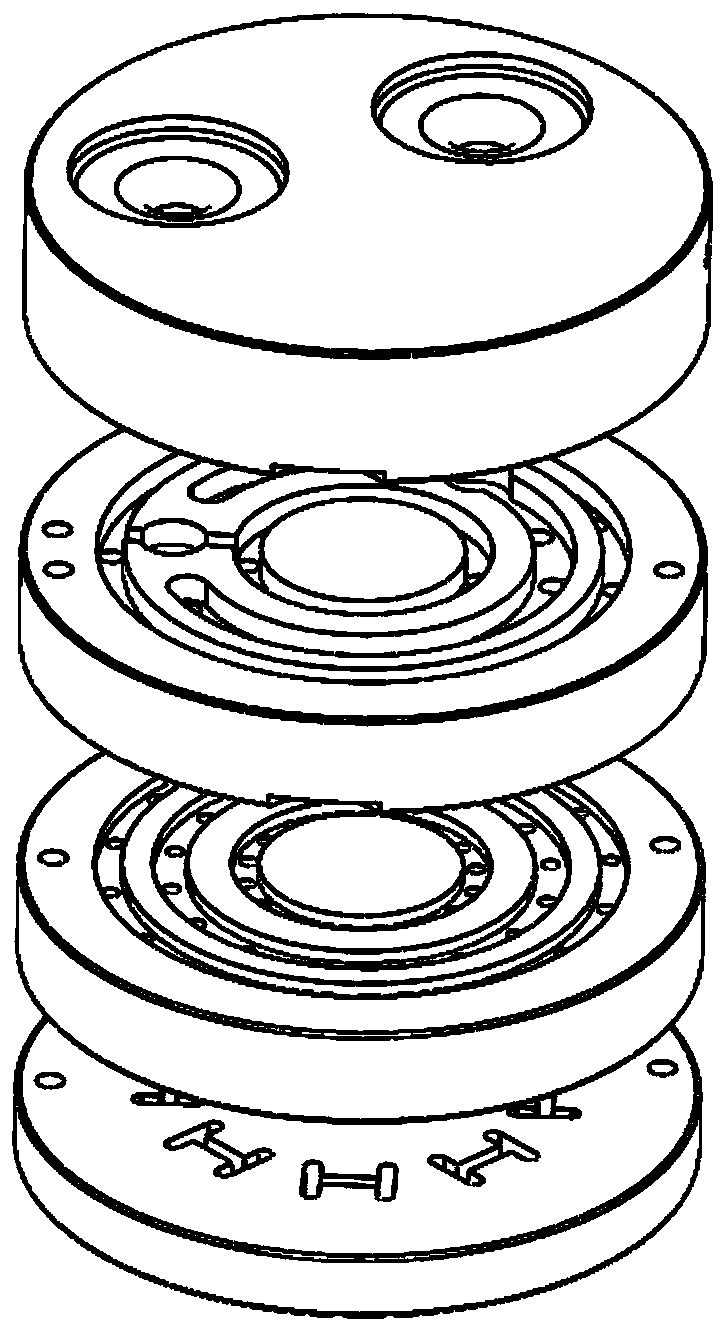

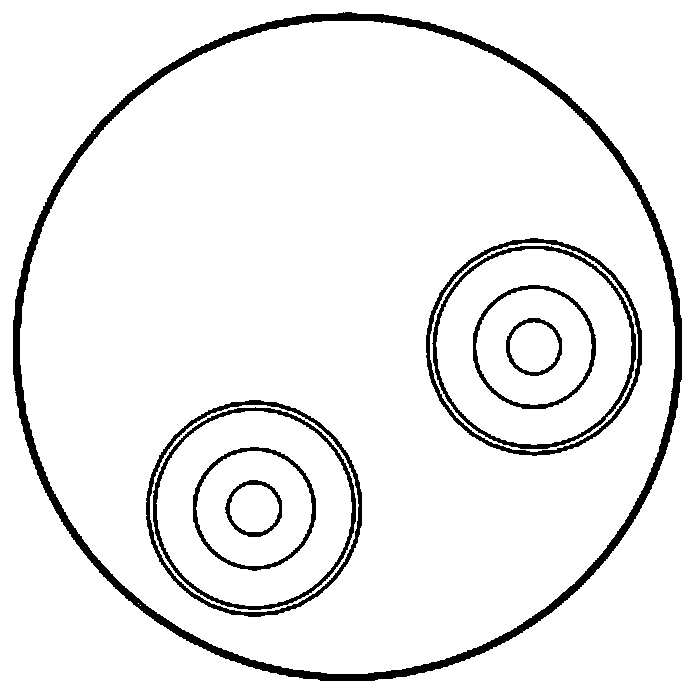

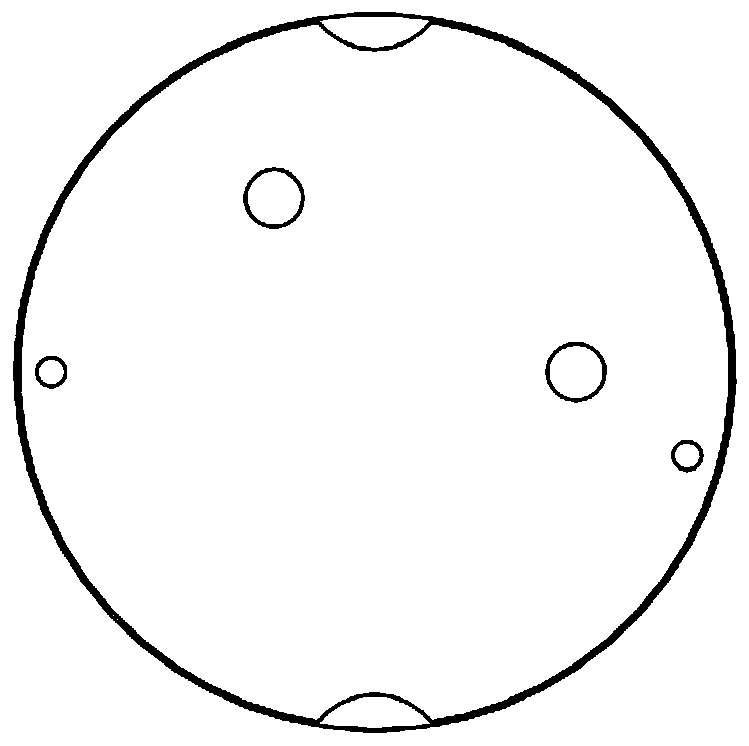

[0051] Such as Figure 1-7 As shown, the composite spinning assembly includes the first distribution plate, the second distribution plate, the third distribution plate and the spinneret that fit closely from top to bottom; the first distribution plate is provided with a flow for the PTT melt to flow through Channel A1 and flow channel B1 for PET melt to flow through; the second distri...

Embodiment 2

[0059] A kind of preparation method of knitted cloth, its steps are as follows:

[0060] (1) The preparation process of shaped fiber is as follows:

[0061] According to the FDY process, using the composite spinning assembly located in the assembly spinning box, PET melt (intrinsic viscosity is 0.58dL / g) and PTT melt (intrinsic viscosity is 1.18dL / g) with a mass ratio of 45:55 ) after distribution, after extruding from the spinneret holes on the same spinneret to obtain FDY filaments, perform relaxation heat treatment at a temperature of 91°C for 26 minutes to obtain special-shaped fibers;

[0062] The composite spinning assembly includes the first distribution plate, the second distribution plate, the third distribution plate and the spinneret that fit closely from top to bottom; the first distribution plate is provided with flow channels A1 and Flow channel B1 for PET melt to flow through; the second distribution plate is provided with outer ring groove O2, middle ring groo...

Embodiment 3

[0070] A kind of preparation method of knitted cloth, its steps are as follows:

[0071] (1) The preparation process of shaped fiber is as follows:

[0072] According to the FDY process, using the composite spinning assembly located in the assembly spinning box, PET melt (intrinsic viscosity is 0.55dL / g) and PTT melt (intrinsic viscosity is 1.1dL / g) with a mass ratio of 45:55 ) after distribution, after extruding from the spinneret holes on the same spinneret to obtain FDY filaments, perform relaxation heat treatment at a temperature of 90°C for 30 minutes to obtain special-shaped fibers;

[0073] The composite spinning assembly includes the first distribution plate, the second distribution plate, the third distribution plate and the spinneret that fit closely from top to bottom; the first distribution plate is provided with flow channels A1 and Flow channel B1 for PET melt to flow through; the second distribution plate is provided with outer ring groove O2, middle ring groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com