A kind of medium and high carbon steel 75cr hot-rolled pickling plate and its production method

A hot-rolled pickling and production method technology, which is applied in the field of steel rolling, can solve the problems affecting the yield of pickled plate products, etc., and achieve the effects of no quality defects, reduced silicon content, and reduced production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

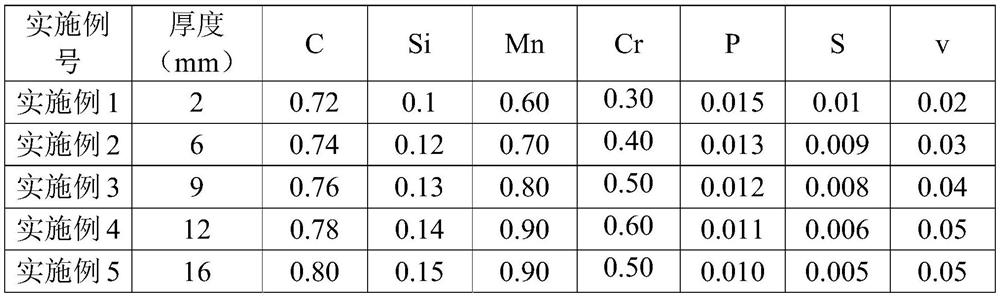

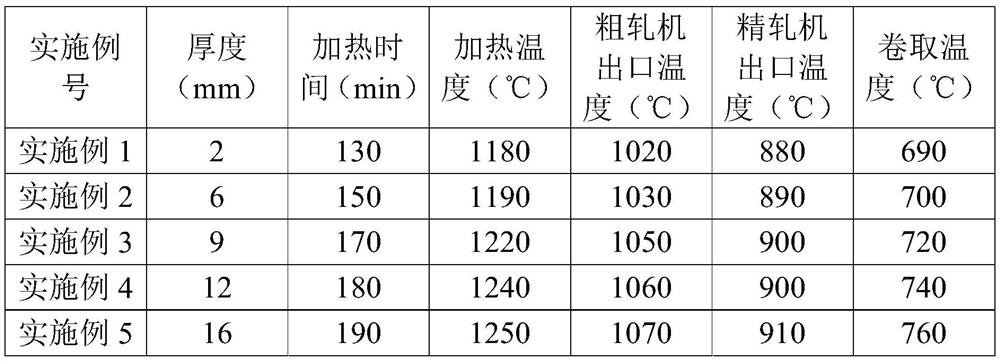

Embodiment 1

[0041] A medium-high carbon steel 75Cr hot-rolled pickling plate, according to weight percentage, its composition includes: C: 0.72%, Si: 0.10%, Mn: 0.60%, Cr: 0.3%, P: 0.015%, S: 0.010%, V: 0.02%, the rest is iron and unavoidable impurities; prepare a qualified slab with the above composition and go through 150 tons of converter vanadium extraction, 150 tons of converter smelting, LF refining, and slab continuous casting; place the slab in Heating in a heating furnace, wherein the temperature of the slab entering the heating furnace is ≥400°C, the heating temperature of the slab in the heating furnace is 1180°C, and the heating time is 130 minutes, and then the slab is taken out of the heating furnace and subjected to high-pressure water Phosphorus removal, the outlet temperature is 1020°C after 5 rough rolling passes in the rough rolling mill, and the exit temperature is 880°C after passing through the hot coil box, and then 7 passes through the finish rolling mill. After dis...

Embodiment 2

[0043] A medium-high carbon steel 75Cr hot-rolled pickling plate, according to weight percentage, its composition includes: C: 0.74%, Si: 0.12%, Mn: 0.70%, Cr: 0.4%, P: 0.013%, S: 0.009%, V: 0.03%, the rest is iron and unavoidable impurities; prepare a qualified slab with the above composition and go through 150 tons of converter vanadium extraction, 150 tons of converter smelting, LF refining, and slab continuous casting; place the slab in Heating in a heating furnace, wherein the temperature of the slab entering the heating furnace is ≥400°C, the heating time of the slab in the heating furnace is 150 minutes, and the heating temperature is 1190°C, and then the slab is taken out of the heating furnace and subjected to high-pressure water Phosphorus removal, the outlet temperature is 1030°C after 5 rough rolling passes through the rough rolling mill, and the exit temperature is 890°C after passing through the hot coil box, and then 7 passes through the finish rolling mill. Afte...

Embodiment 3

[0045] A medium-high carbon steel 75Cr hot-rolled pickling plate, according to weight percentage, its composition includes: C: 0.76%, Si: 0.13%, Mn: 0.80%, Cr: 0.5%, P: 0.012%, S: 0.008%, V: 0.04%, the rest is iron and unavoidable impurities; prepare a qualified slab with the above composition and go through 150 tons of converter vanadium extraction, 150 tons of converter smelting, LF refining, and slab continuous casting; place the slab in Heating in a heating furnace, wherein the temperature of the slab entering the heating furnace is ≥400°C, the heating time of the slab in the heating furnace is 170 minutes, and the heating temperature is 1220°C, and then the slab is taken out of the heating furnace and subjected to high-pressure water Phosphorus removal, the outlet temperature is 1050°C after 5 rough rolling passes through the rough rolling mill, and the exit temperature is 900°C after passing through the hot coil box, and then 7 passes through the finish rolling mill. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com