Preparation method of pen point of mark pen

A nib and mark technology, applied in the fiber field, can solve the problems of poor writing experience of marker pens and the inability to use high-end marker products, and achieve the effect of taking into account performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

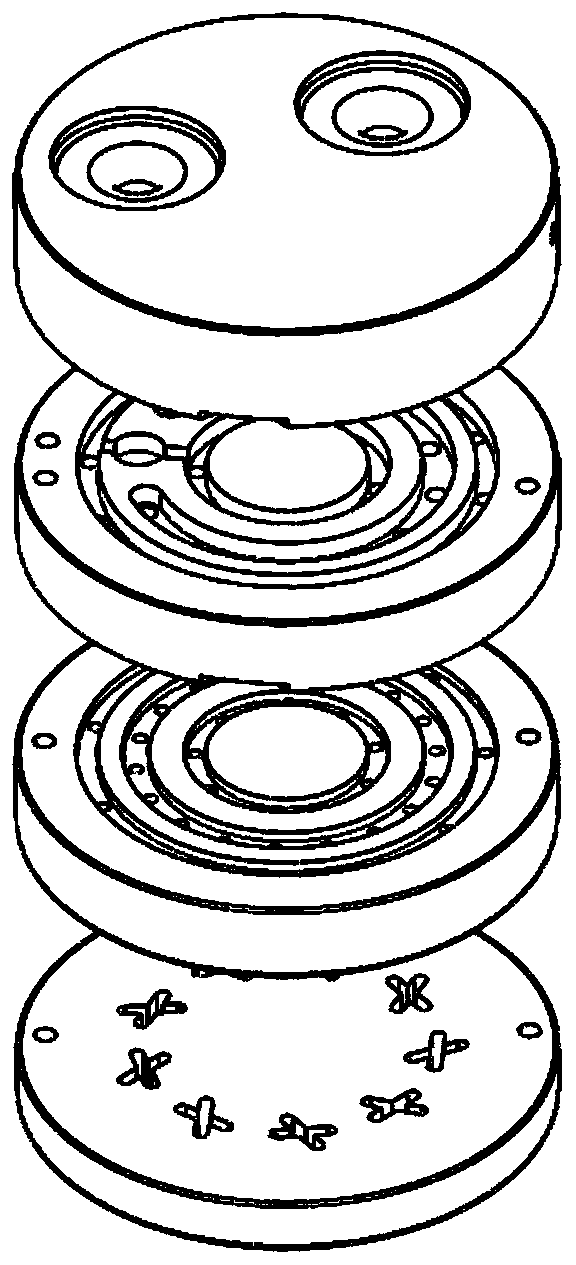

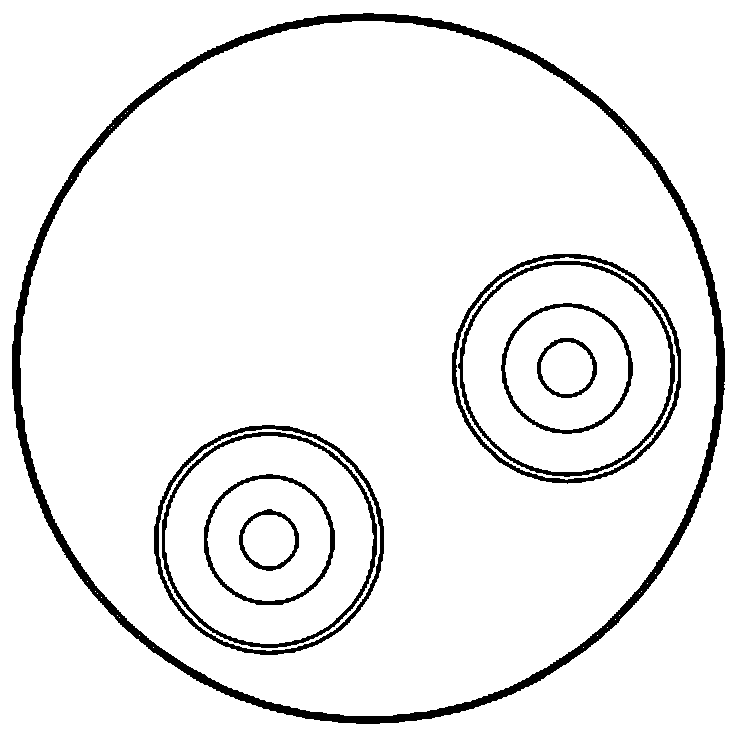

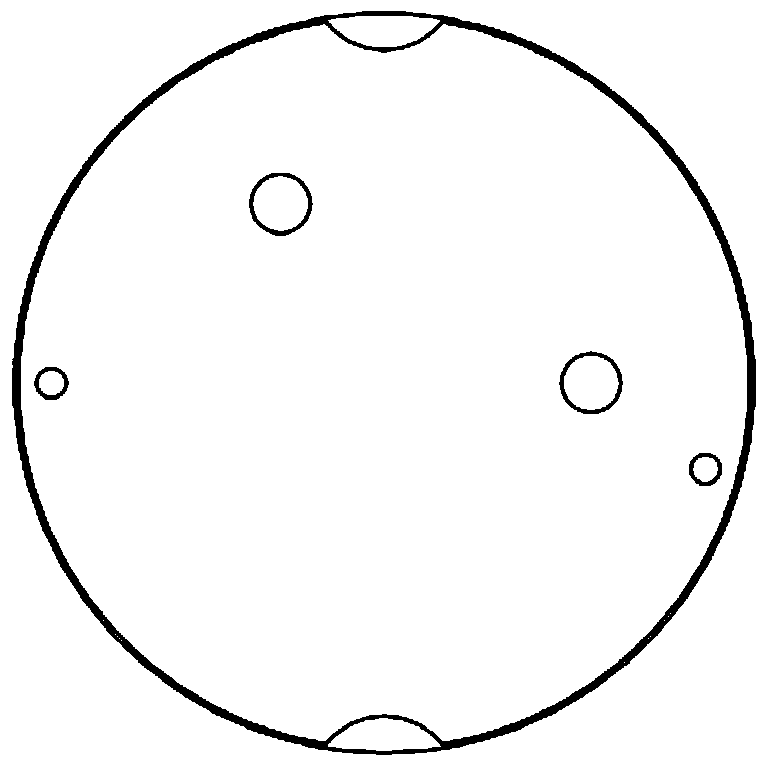

Image

Examples

Embodiment 1

[0055] A preparation method for a marker tip, the steps are as follows:

[0056] (1) the nib of 1.3dtex is washed and dried with polyamide fiber to monofilament fineness;

[0057] Wherein, the preparation process of the polyamide fiber for the nib is as follows:

[0058] According to the FDY process, the high viscosity PA6 melt (intrinsic viscosity is 2.59dL / g) and the low viscosity PA6 melt (intrinsic viscosity is 2.26dL / g) with a mass ratio of 45:55 are distributed, and then from the same spinneret After the spinneret holes are extruded to obtain FDY filaments, relaxation heat treatment is carried out to obtain polyamide fibers for pen heads;

[0059] The spinneret holes on the spinneret are shaped spinneret hole, The shape is composed of a horizontal line and the oblique line I and II connected with it; the angle between the oblique line I and the horizontal line is 43°, and the angle between the oblique line II and the horizontal line is 65°; oblique line I, oblique l...

Embodiment 2

[0071] A preparation method for a marker tip, the steps are as follows:

[0072] (1) the nib of 1dtex is washed and dried with polyamide fiber to monofilament fineness;

[0073] Wherein, the preparation process of the polyamide fiber for the nib is as follows:

[0074] According to the FDY process, the high viscosity PA6 melt (intrinsic viscosity is 2.5dL / g) and the low viscosity PA6 melt (intrinsic viscosity is 2.2dL / g) with a mass ratio of 40:60 are distributed, and then from the same spinneret After the spinneret holes are extruded to obtain FDY filaments, relaxation heat treatment is carried out to obtain polyamide fibers for pen heads;

[0075] The spinneret hole is shaped spinneret hole, The shape is composed of a horizontal line and the oblique line I and II connected with it; the angle between the oblique line I and the horizontal line is 40°, and the angle between the oblique line II and the horizontal line is 60°; oblique line I, oblique line II The ratio to th...

Embodiment 3

[0087] A preparation method for a marker tip, the steps are as follows:

[0088] (1) the nib of 1.3dtex is washed and dried with polyamide fiber to monofilament fineness;

[0089] Wherein, the preparation process of the polyamide fiber for the nib is as follows:

[0090] According to the FDY process, the high-viscosity PA6 melt (intrinsic viscosity is 2.5dL / g) and the low-viscosity PA6 melt (intrinsic viscosity is 2.29dL / g) with a mass ratio of 45:55 are distributed from the same spinneret After the spinneret holes are extruded to obtain FDY filaments, relaxation heat treatment is carried out to obtain polyamide fibers for pen heads;

[0091] The spinneret hole is shaped spinneret hole, The shape is composed of a horizontal line and the oblique line I and II connected with it; the angle between the oblique line I and the horizontal line is 42°, and the angle between the oblique line II and the horizontal line is 61°; oblique line I and oblique line II The ratio to the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com