A safe hot-melt seamless splicing machine for inkjet cloth

A technology of seamless splicing machine and inkjet cloth, which is applied in the field of inkjet cloth hot-melt seamless splicing machine, can solve the problems of time-consuming and material, difficult to guarantee bonding strength, etc., and achieve the effect of improving safety and strong splicing firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

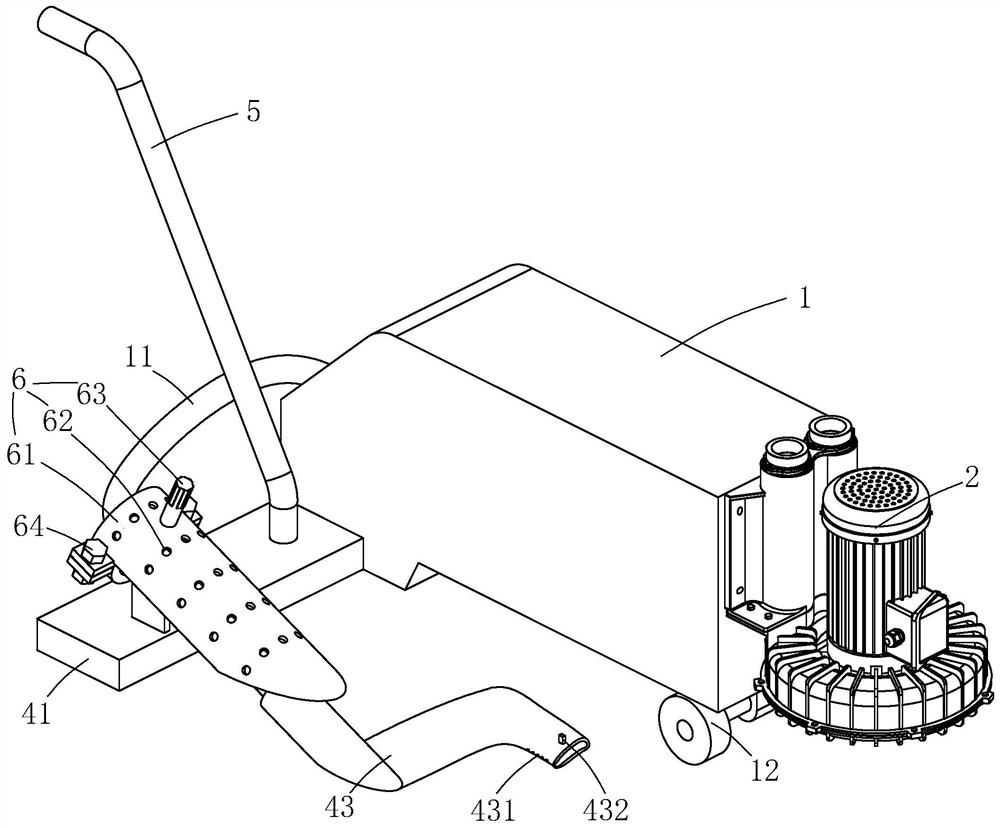

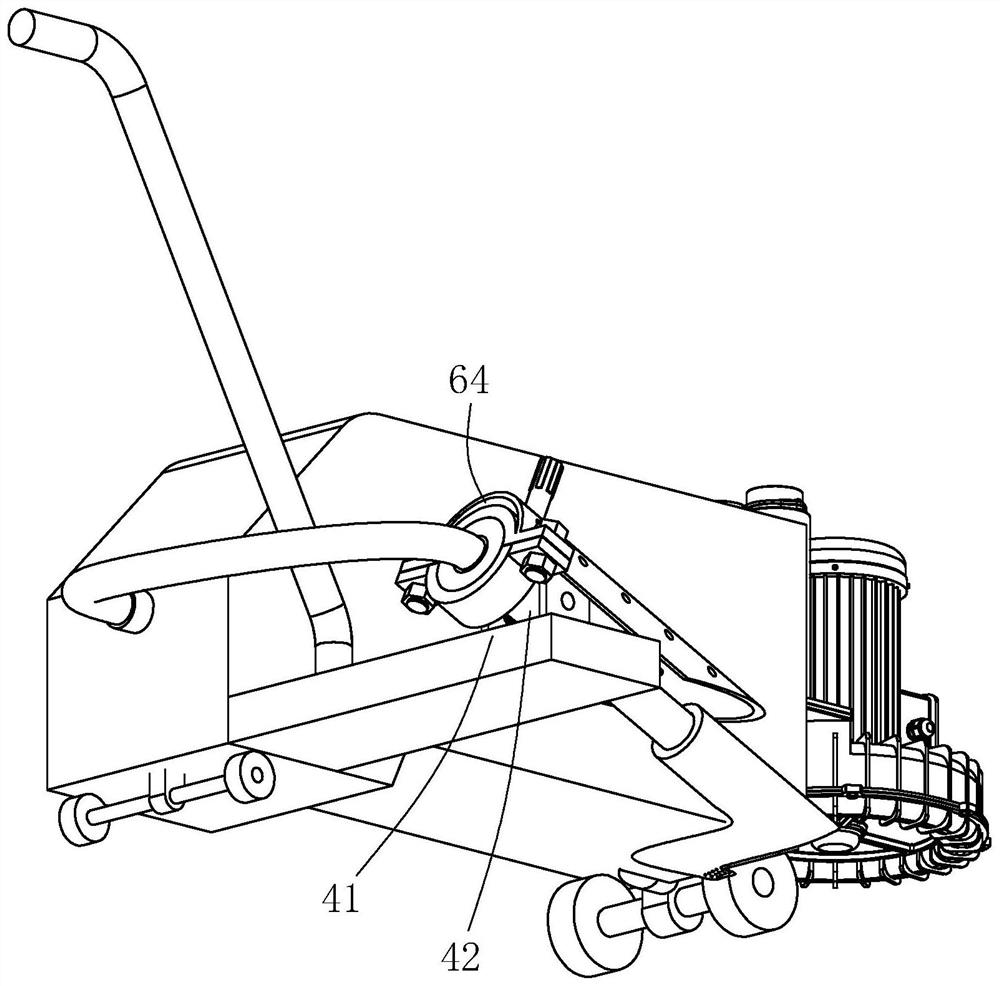

[0039] refer to figure 1 , which is a safe heat-melt seamless splicing machine for inkjet cloth disclosed in the present invention, includes a cuboid-shaped chassis 1 , an air pump 2 , a heating component 3 and a heat-pressing component 4 . The four corners of the bottom of the cabinet 1 are fixedly connected with four guide wheels 12, the air pump 2 is fixed on one end of the cabinet 1, and the other end of the cabinet 1 is fixedly connected with a push handle 5, so that the staff can push the cabinet 1 forward.

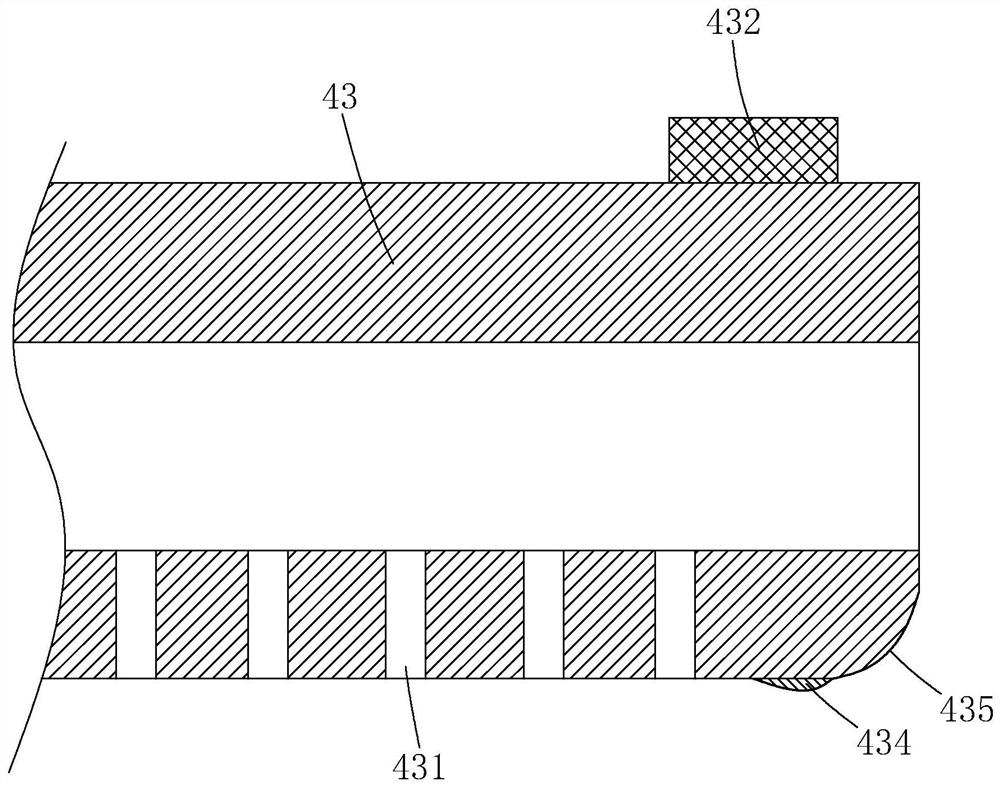

[0040] Specifically, the heating assembly 3 includes a heating chamber fixed in the cabinet 1, an electric heating network, an air inlet pipe, and an air outlet pipe. The cabinet 1 is fixed with an outlet pipe 11 communicating with the heating chamber. Connected, the other end is communicated with the air outlet end of the air pump 2, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com