Shearing box for testing anisotropy of rock sample structural surface and using method thereof

A rock sample, anisotropic technology, applied in the direction of applying stable shear force to test material strength, measuring device, strength characteristics, etc., can solve the problem that the shear strength anisotropy characteristics of rock structural planes cannot be obtained, and cannot be obtained Problems such as rock mass and difficult operation, to achieve the effect of enriching the research of anisotropic shear test, enriching the anisotropy of shear strength, and facilitating the detection of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

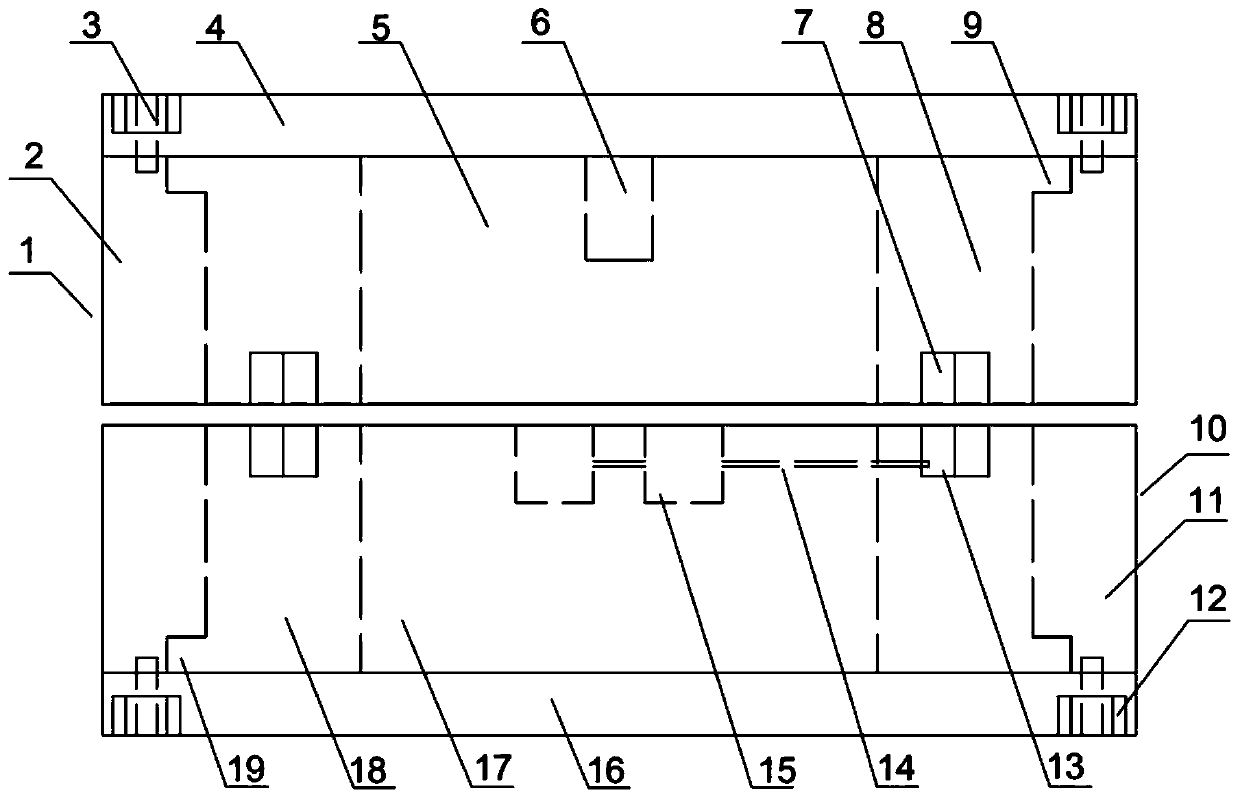

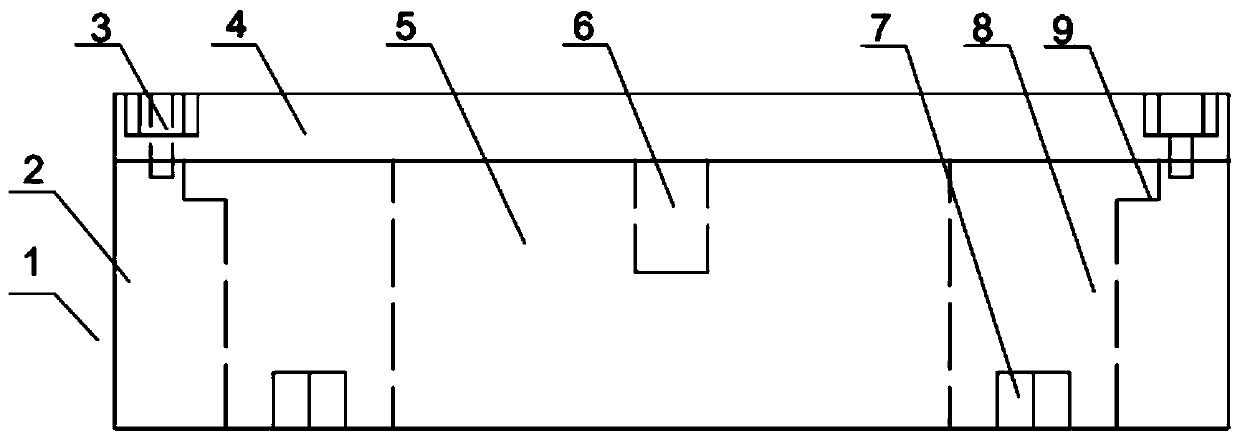

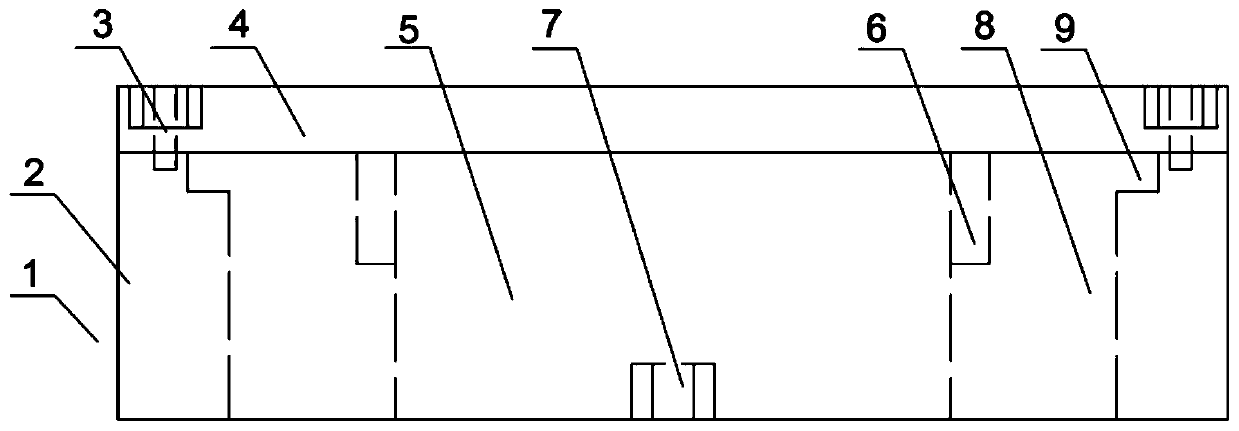

[0062] An anisotropic shear cell for testing specimens of rock discontinuities such as figure 1 , Fig. 2, Fig. 3, Fig. 4, shown in Fig. 5, shearing box comprises upper shearing box 1, lower shearing box 10 and rotating body. The upper shear box 1 is composed of a top plate 4, an upper fixed frame 2, and four first fastening bolts 3, as shown in Figures 2 and 3; the lower shear box 10 is composed of a bottom plate 16, a lower fixed frame 11, and four first fastening bolts 3 Composed of two fastening bolts 12, as shown in Figure 4 and Figure 5; the four first fastening bolts 3 of the top plate are connected with the upper fixing frame 2 through bolt holes, and the four second fastening bolts 12 of the bottom plate are passed through the bolt holes It is connected with the lower fixing frame 11 by bolts, as shown in Fig. 3 and Fig. 5 .

[0063] Such as figure 1 , FIG. 2 , FIG. 3 , FIG. 4 , and FIG. 5 , the rotating body includes an upper rotating body 8 and a lower rotating bod...

Embodiment 2

[0076] A shear cell for testing the anisotropy of the structural plane of a rock sample and a method for using the same.

[0077] In this embodiment, refer to figure 1 , Fig. 2, Fig. 3, Fig. 4, and Fig. 5, the test square sample a × b × h = 100mm × 100mm × 100mm, at this time, the upper half cavity 5 and the lower half cavity 17 are directly used as placing shear samples chamber, such as figure 1 As shown, the method of use includes the following steps:

[0078] (1) Use an Allen wrench to loosen the four second fastening bolts 12, insert the Allen wrench into the lower hexagon bolt hole 13, rotate the lower dial 23 to align with the lower scale pointer 22, and tighten the four second fastening bolts 12, Put the lower half of the rock sample into the lower half cavity 17;

[0079] (2) Loosen the first fastening bolt 3, turn the upper shear box 1 upside down and insert the upper hexagonal wrench into the upper hexagonal bolt hole 7, rotate the upper dial 21 to align with the ...

Embodiment 3

[0082] A shear cell for testing the anisotropy of the structural plane of a rock sample and a method for using the same.

[0083] Present embodiment, as Fig. 7, Fig. 8, Figure 9 As shown, to test a smaller square sample a×b×h=75mm×75mm×75mm, it is necessary to clamp the upper size adjustment frame 24 in the upper rotating body 8, and the lower rotating body 18 to clamp the lower size adjustment frame 28, wherein, The upper size adjustment frame 24 is made up of the first size rectangular gap 25, the upper boss 26 and the upper size adjustment frame groove, and the lower size adjustment frame 18 is composed of the second size rectangular gap 30, the lower boss 29 and the lower size adjustment frame groove Composition, use allen wrench to loosen four first fastening bolts 3, open top plate 4 and put the upper boss 26 of upper size adjustment frame 24 into the first rectangular gap 6, the first size rectangular gap 25 and the upper size adjustment frame concave The groove const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com