Intelligent adjusting method for noise of extractor hood

A range hood, intelligent adjustment technology, applied in the direction of removing oil fume, heating method, mechanical equipment, etc., can solve the problem of not being able to truly reflect the operating state of oil fume, unable to realize self-adaptive adjustment, unclear setting position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

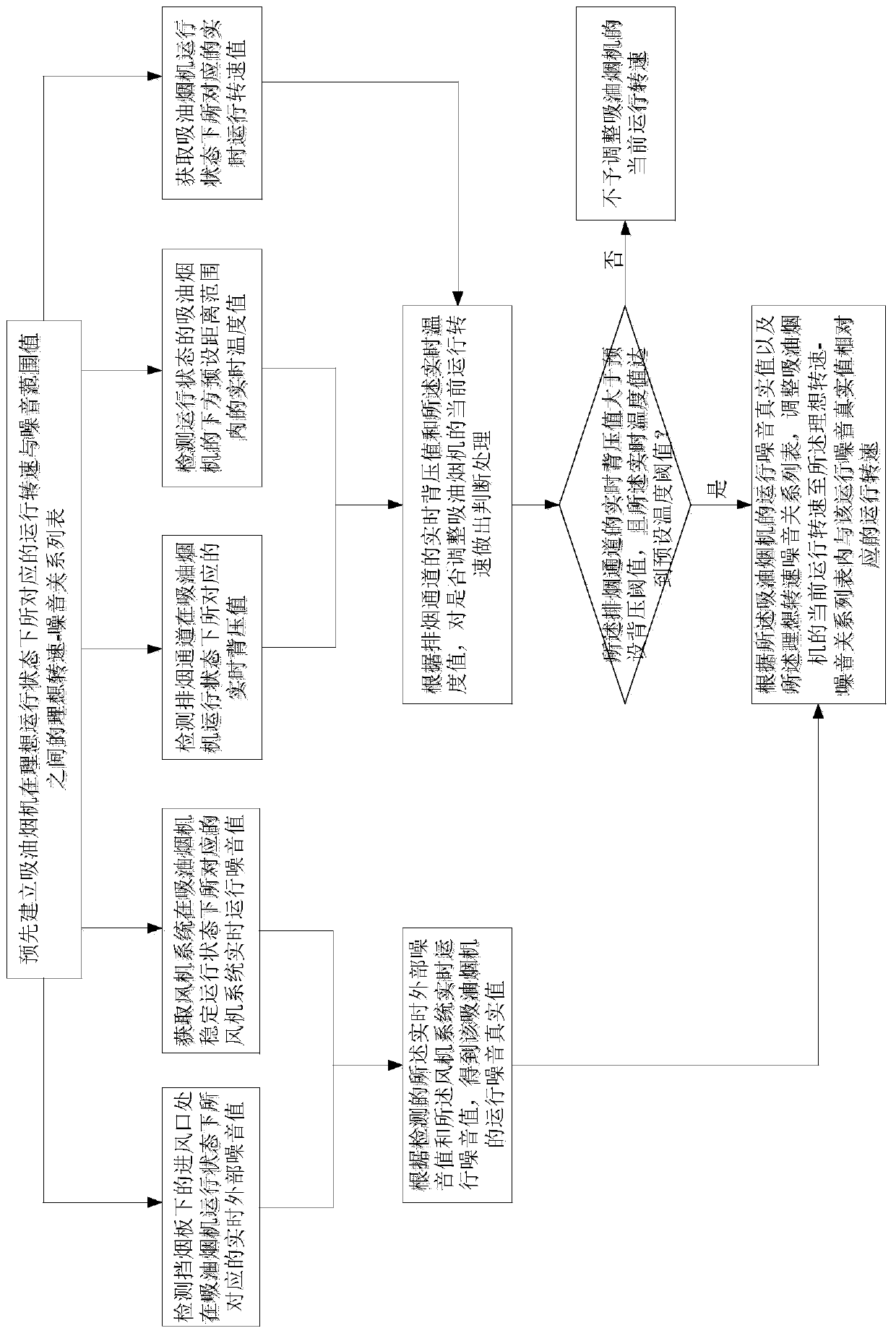

[0049] Such as figure 1 As shown, this embodiment provides an intelligent adjustment method for range hood noise, which specifically includes the following steps 1 to 9:

[0050] Step 1, pre-establish the ideal speed-noise relationship list between the operating speed and noise range value corresponding to the range hood in the ideal operating state; wherein, the operating speed and noise range values in the ideal speed-noise relationship list are one by one Corresponding; the "ideal operating state" mentioned here refers to the operating state of the range hood at its rated power; it is generally believed that the noise generated by the range hood when it is operating at the rated power will not affect the user's experience. Negative Effects;

[0051] For example, assume that in the ideal speed-noise relationship list established, the ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com