Safe cold and hot water faucet

A technology for hot and cold water and faucet, applied in the field of faucets, can solve the problems of low control accuracy, scalding of hot and cold water faucets, inability to clean faucets and faucets, etc., and achieves the effects of accurate output ratio, safe use, and prevention of scalding accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

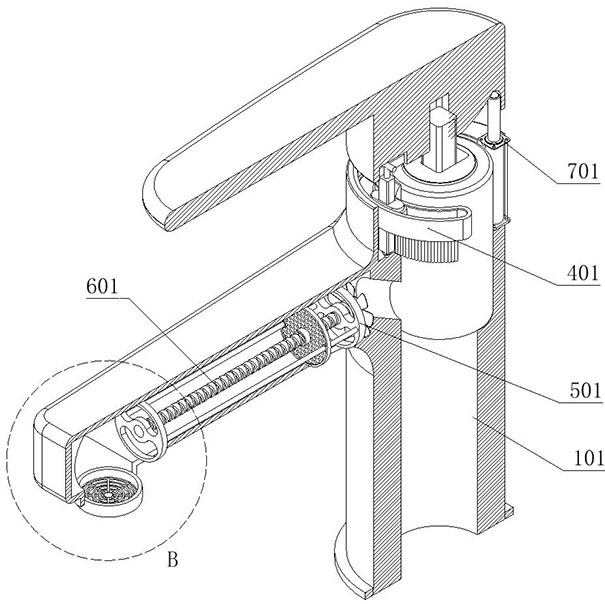

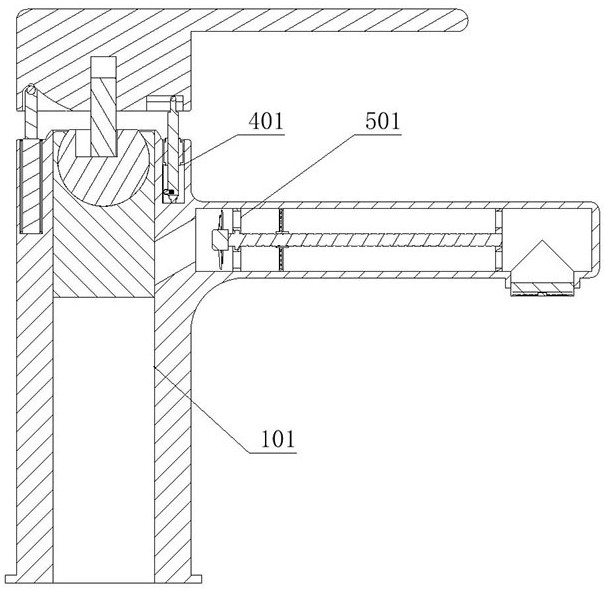

[0077] as attached figure 1 to attach Figure 12 Shown:

[0078] The present invention provides a safe hot and cold water faucet, which includes a main body device 1;

[0079] A sealing ring 8 is installed on the bottom of the main device 1; a control device 2 is installed on the main device 1; a water passage device 3 is fixedly connected to the main device 1, and a support device 5 is fixedly connected inside the water passage device 3; There is a driving part 6; an adjustment control part 4 is installed on the main device 1; the control device 2 includes: a control handle 201, which is provided with a valve body installation hole 205; a centering chute 202, which is set on On the rear side of the control handle 201, the centering chute 202 is a concave arc-shaped structure; the positioning hole 203 is set in the middle of the centering chute 202; the homing device 7 is fixedly connected to the main device 1 superior.

[0080] as attached Figure 4 , attached Figure 5...

Embodiment 2

[0083] as attached Figure 8 , attached Figure 9 As shown, the adjustment control part 4 includes: an arc track 401, which is fixedly connected to the top of the control installation groove 103; There is a rectangular through hole on the top; the adjustment control part 4 also includes: a lifting trigger rod 403, which is slidably set in the rectangular through hole of the moving slider 402; a linkage rod 404, which is a "T" shaped structure, And the linkage rod 404 is fixedly connected to the lifting trigger rod 403; the top of the linkage rod 404 is slidably connected to the adjustment chute 204; the wave plate 405, the wave plate 405 is fixedly connected to the bottom of the arc track 401; the controller 406, the controller 406 is fixed Connected to the lower part of the lifting trigger lever 403; trigger switch 407, the trigger switch 407 is fixedly connected to the bottom of the lifting trigger lever 403; the adjustment control part 4 also includes: an adjustment spring...

Embodiment 3

[0085] On the basis of Embodiment 1, this embodiment provides another structural form of positioning ball 702 to solve the problem of serious wear and tear of positioning ball 702 after long-term use. The homing device 7 includes: electric telescopic rod 701, which is fixed Connected to the main pipe 101; the positioning ball 702, the positioning ball 702 is set on the shaft end of the electric telescopic rod 701; by installing a rubber pad on the surface of the positioning ball 702 or directly replacing the positioning ball 702 with a high-hardness rubber ball, the positioning is reduced. The wear of the ball 702 improves the service life of the positioning ball 702 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com