Bridge abutment construction method

A construction method and abutment technology, applied to excavation, bridges, bridge parts, etc., can solve the problems of large construction site, large excavation height, loose slope, etc., achieve small construction site, avoid reduction of bearing capacity, reduce cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

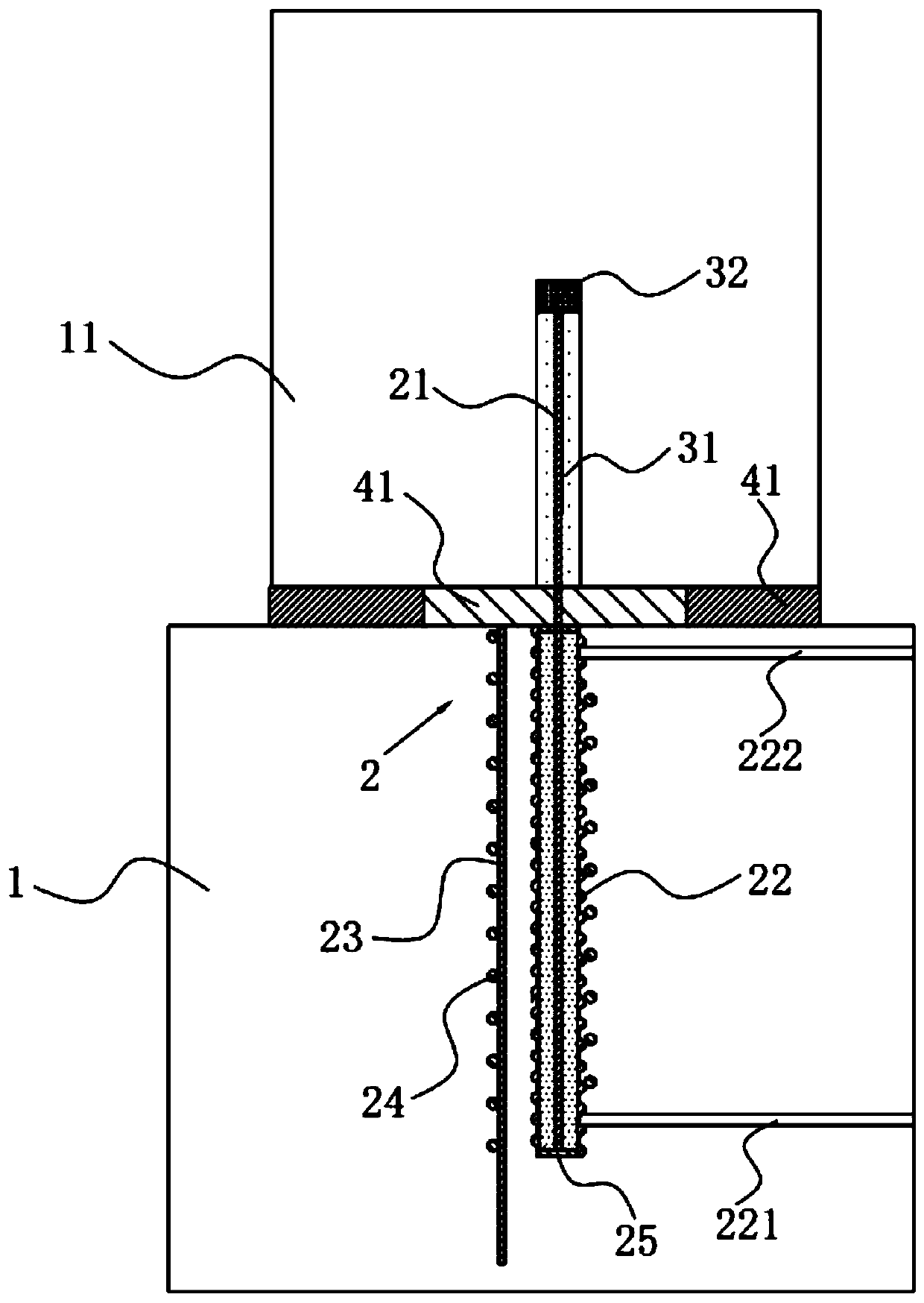

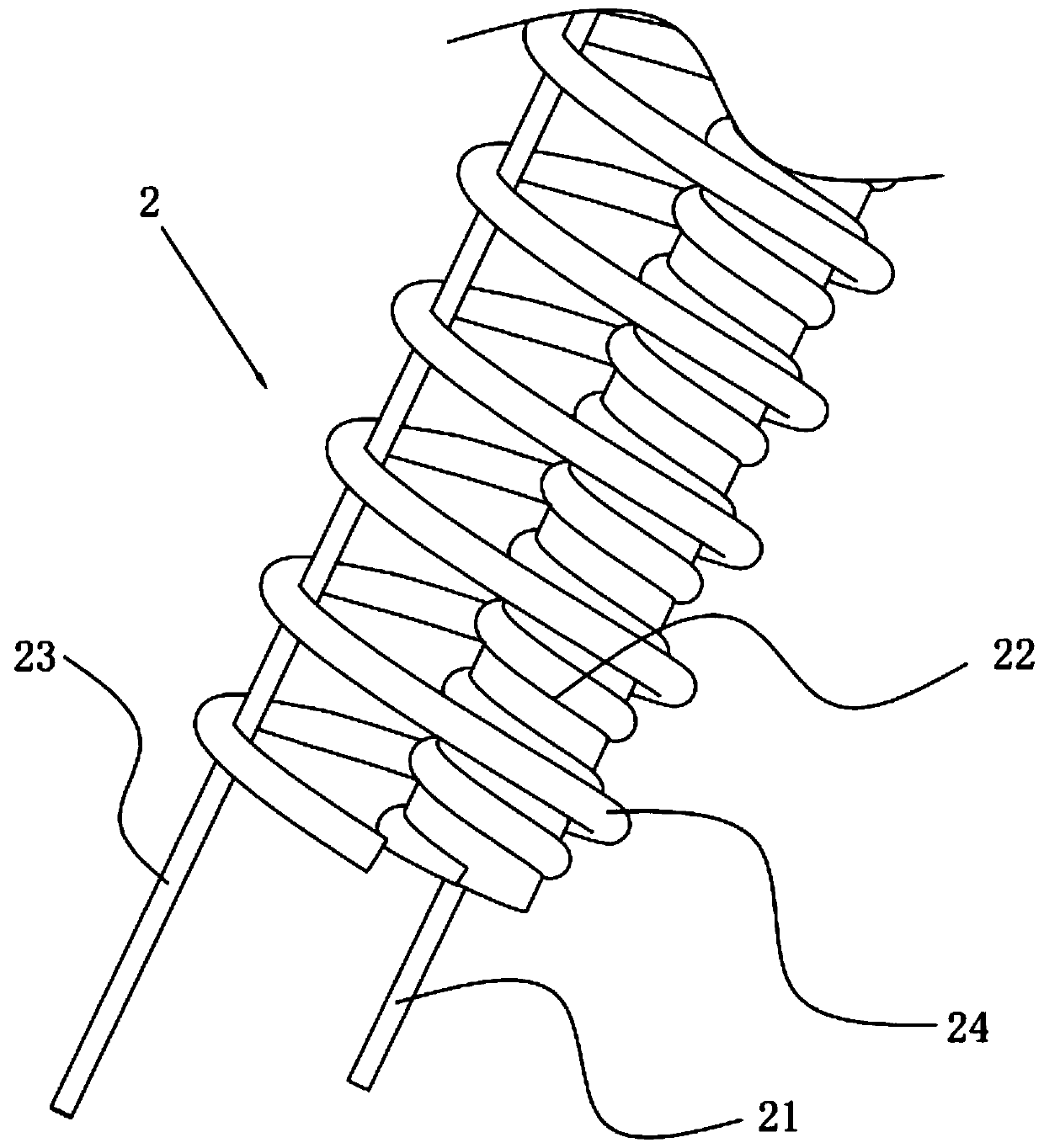

[0040] An abutment structure such as figure 1 As shown, including platform 1 , there is platform body 11 above platform 1 , platform body 11 is rotatably connected with platform 1 through connector 2 , specifically, platform body 11 is located on the top surface of platform 1 . In order to reduce the constraint displacement caused by the temperature load, reduce the lateral (along the width direction of the platform 1) and lateral (along the length direction of the platform 1) displacement of the platform 1, and reduce the influence of the instantaneous displacement of the platform body 11 on the platform 1, the platform The connection between the body 11 and the cap 1 is designed to be rotatable and hinged, so that the influence of the superstructure (that is, the platform body 11) on the pile foundation (that is, the cap 1) can be transferred, part of the rotational kinetic energy can be released, and large damage to the pile foundation can be avoided. Lateral displacement a...

Embodiment 2

[0049] A kind of bridge abutment construction method, at first artificially removes the dangerous stone on the side slope outside the tunnel, temporarily supports the side slope (back pressure, filling joints and anchor spray support), cleans up the loose body of the side slope outside the tunnel, and opens the foundation trench Excavation (excavation to the bottom of the cap), construction of excavated piles, construction of the cap, construction of the platform body, permanent support of the slope (grid beam anchor cable).

[0050] The specific construction method is:

[0051] S1. First, clean up the dangerous stones on the slope outside the tunnel, and then seal them with plain spray C25 concrete. The thickness of the spray is 8cm;

[0052] S2. Bolt and shotcrete support is carried out on the outer side slope of the tunnel from top to bottom. The anchor rod adopts φ22mm mortar bolt. Net, the grid spacing of the steel mesh is 20cm×20cm, connect the steel mesh to the mortar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com