Production process of back piece of backpack

A production process, technology of backpacks, applied in the field of backpacks, can solve problems such as sweat can not be evaporated in time, lack of air permeability, bacterial growth, etc., to reduce bacterial growth, improve sweating ability, and prevent skin problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

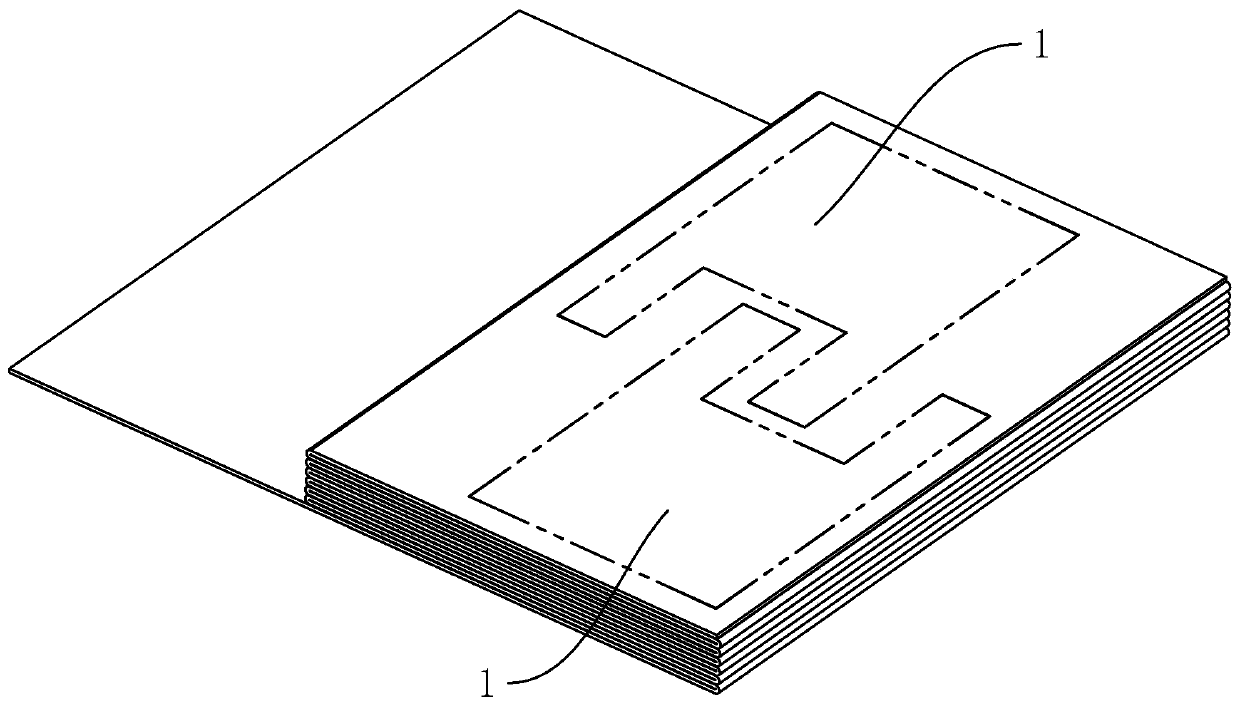

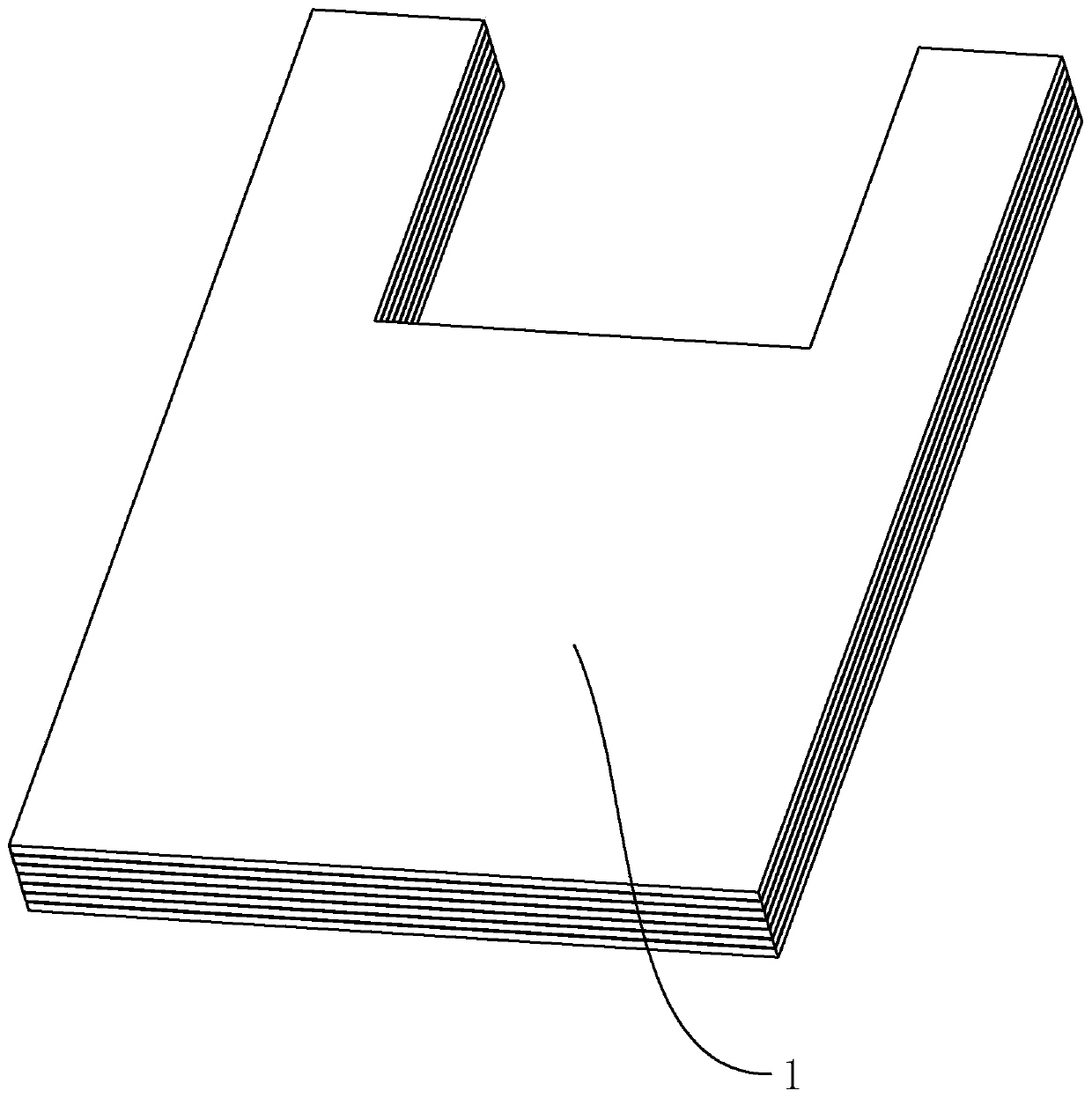

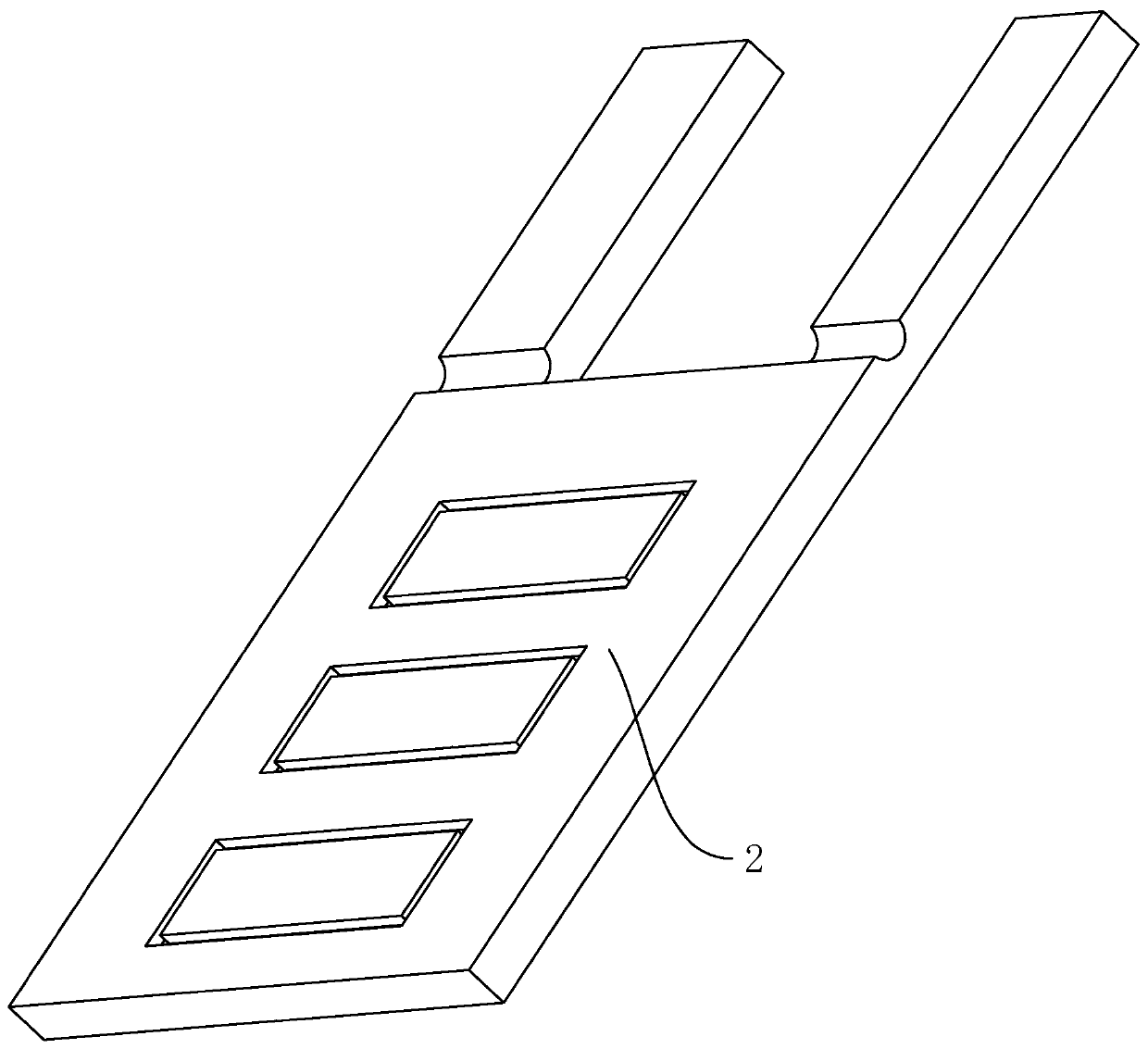

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] A production process for the back panel of a backpack, comprising the following steps: step S1, carding DuPont sorona fibers into a thin net state through a roller carding machine, and sending them to a web laminating machine for standby, mixing oyster fibers with a roller carding machine and hot-melting short The fiber is carded into a thin net state, sent to the web-laying machine and laid on the top of the sorona fiber, and the fiber web with a grammage of 10-40 grams per square meter is obtained from the web-laying, and the fiber web is finally wound up; DuPont sorona fiber is used as the basic material Lay the net to prepare the fiber web, so as to make use of its excellent stretchability and recovery ability to ensure the elasticity of the fiber web, and then meet the elastic requirements of the backpack back panel 4, add hot-melt short fibers, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com