Special ejector for picanol air jet loom

A technology of air-jet looms and jets, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of yarn inlet position wear, fast yarn rebound speed, affecting service life, etc., to prevent serious wear and tear. The effect of good wear resistance and prolonging the overall service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

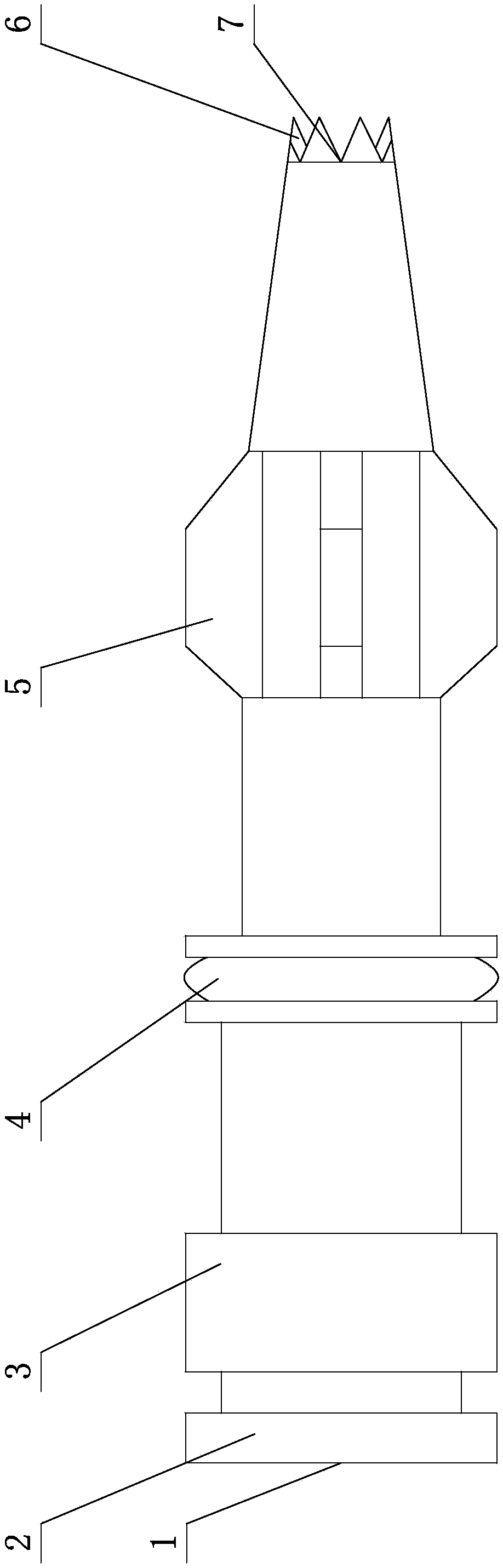

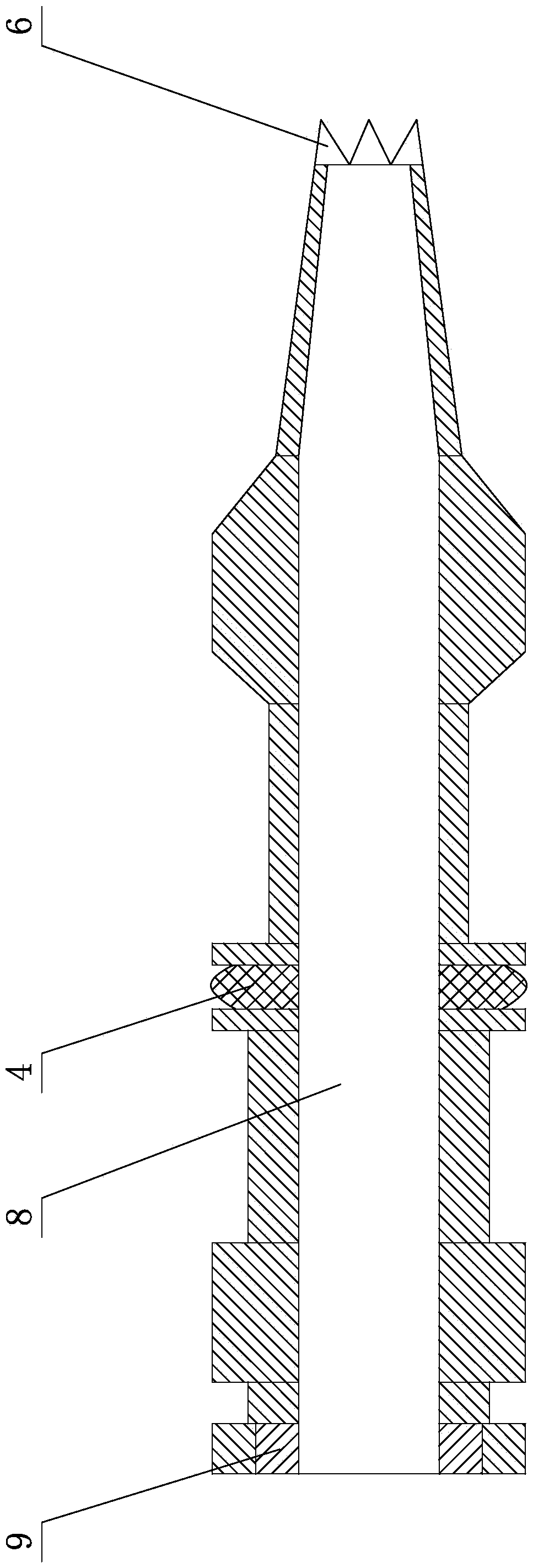

[0016] Such as figure 1 with figure 2 , the special injector for picanol air-jet loom of the present invention comprises injector body 2, and the central position of injector body 2 along the axial direction is provided with weft insertion channel 8, and one end of weft insertion channel 8 is yarn inlet 1, and another One end is the yarn outlet 7, the weft insertion channel 8 at one end of the yarn inlet 1 is provided with a ceramic ring 9, the ceramic ring 9 is provided with a through hole, and the outer wall of the ceramic ring 9 is fixed to the weft insertion channel 8 wall; the yarn outlet 7 is at one end The end of the injector body 2 is provided with an annular sawtooth nozzle 6. The annular sawtooth nozzle 6 includes a number of serrations uniformly arranged along the circumference.

[0017] In this example:

[0018] An annular sealing ring 4 is provided in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com