PVC sizing material, and preparation method and application thereof

A technology of PVC resin and glue, which is applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc. It can solve the problems of poor comprehensive performance and achieve excellent oil resistance, simple and easy preparation method, and matte surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] The of the present invention provides a method for preparing the PVC compound according to the , the preparation method comprising the step of mixing and granulating the various components of the PVC compound.

[0082] In some specific embodiments of the present invention, the preparation method includes the following steps:

[0083] Mixing the components of the PVC compound to obtain a mixture;

[0084] The mixture is banburyed to obtain block;

[0085] The blocks are granulated to obtain PVC sizing material.

[0086] mix

[0087] The preparation method of the present invention includes the step of mixing various components of the PVC rubber material to obtain a mixture. The embodiment of the mixing step is not particularly limited in the present invention, and may be a common mixing method in the art. For example, high-speed kneaders can be used for mixing.

[0088] In some specific embodiments of the present invention, the mixing includes: mixing heat stabili...

Embodiment

[0111] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention. Those who do not indicate the specific conditions in the examples are carried out according to the conventional conditions or the conditions suggested by the manufacturer. The reagents or instruments used were not indicated by the manufacturer, and they were all commercially available conventional products.

[0112] 1. Experimental materials

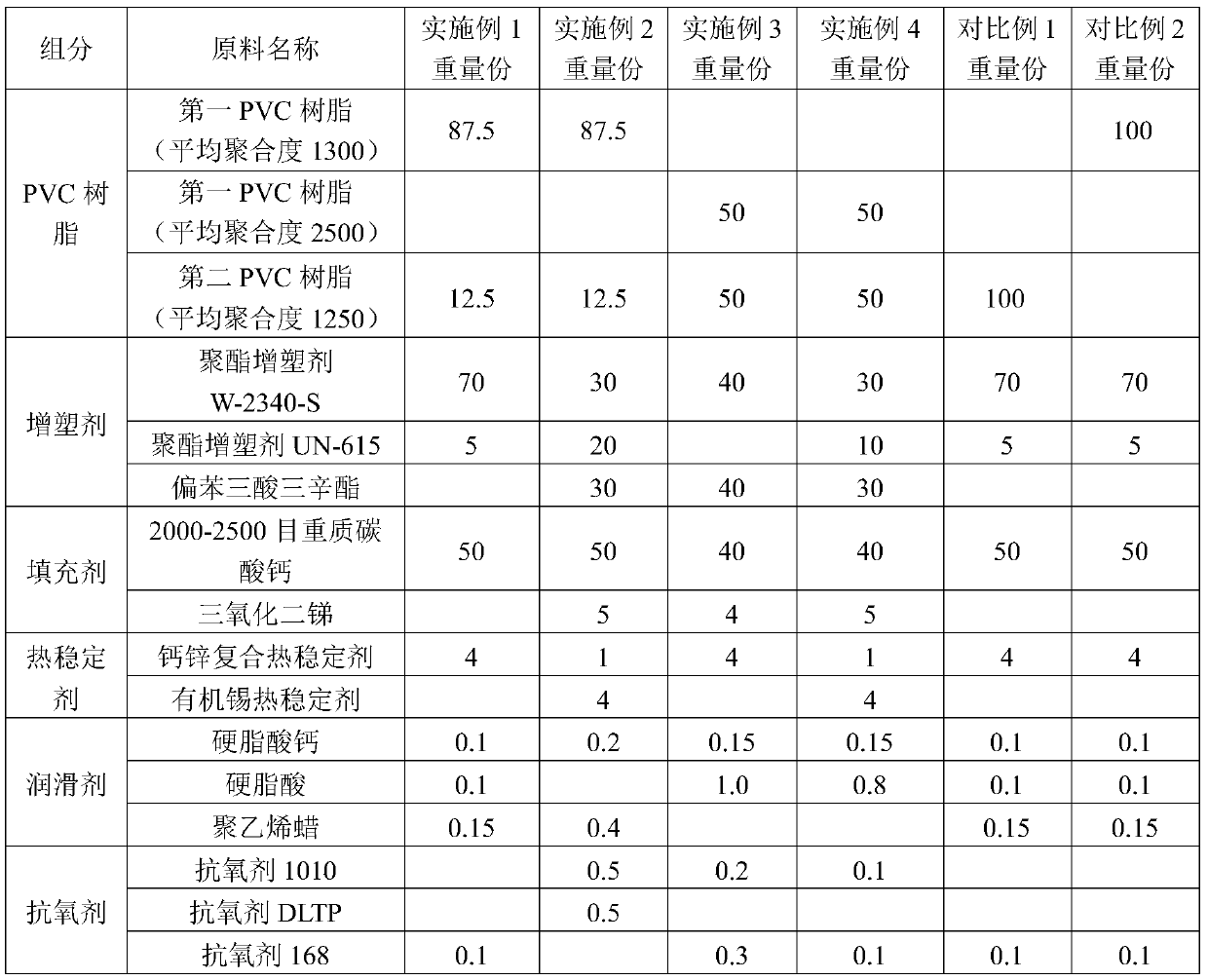

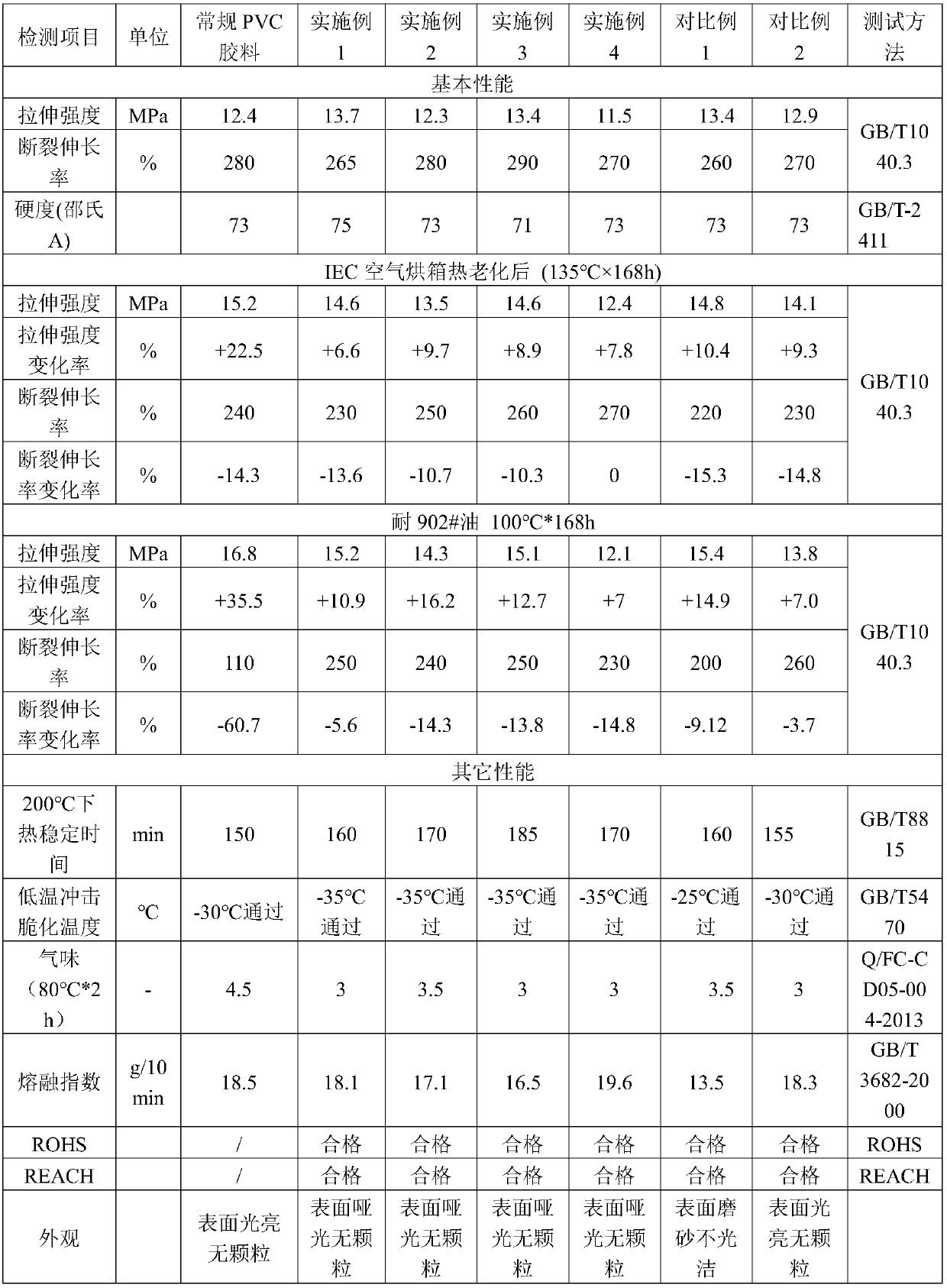

[0113] The composition and proportioning of raw materials are shown in Table 1 below. in,

[0114] The first PVC resin (average degree of polymerization 1300): manufacturer: Ningbo Formosa Plastics Company, model: S-70;

[0115] The first PVC resin (average degree of polymerization 2500) manufacturer: Ningbo Formosa Plastics Compan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com