EVA sockliner and preparation process thereof

A technology of insoles and tangerines, applied in the field of EVA insoles and its preparation technology, to achieve good antibacterial and disinfection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

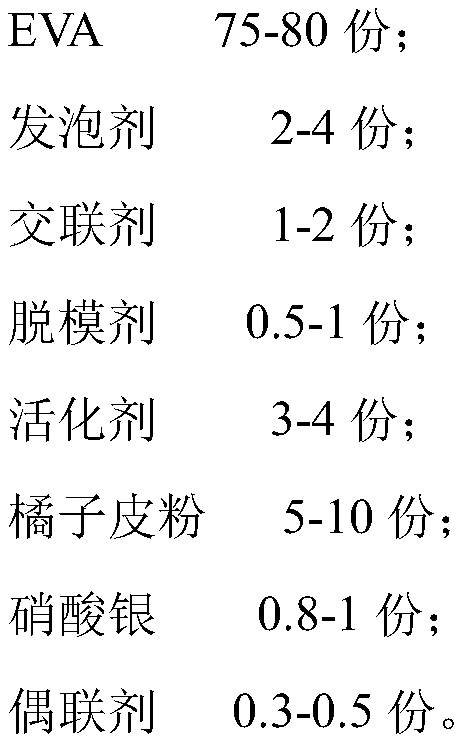

[0051] An EVA insole, calculated in parts by weight, and its raw material components are shown in Table 1.

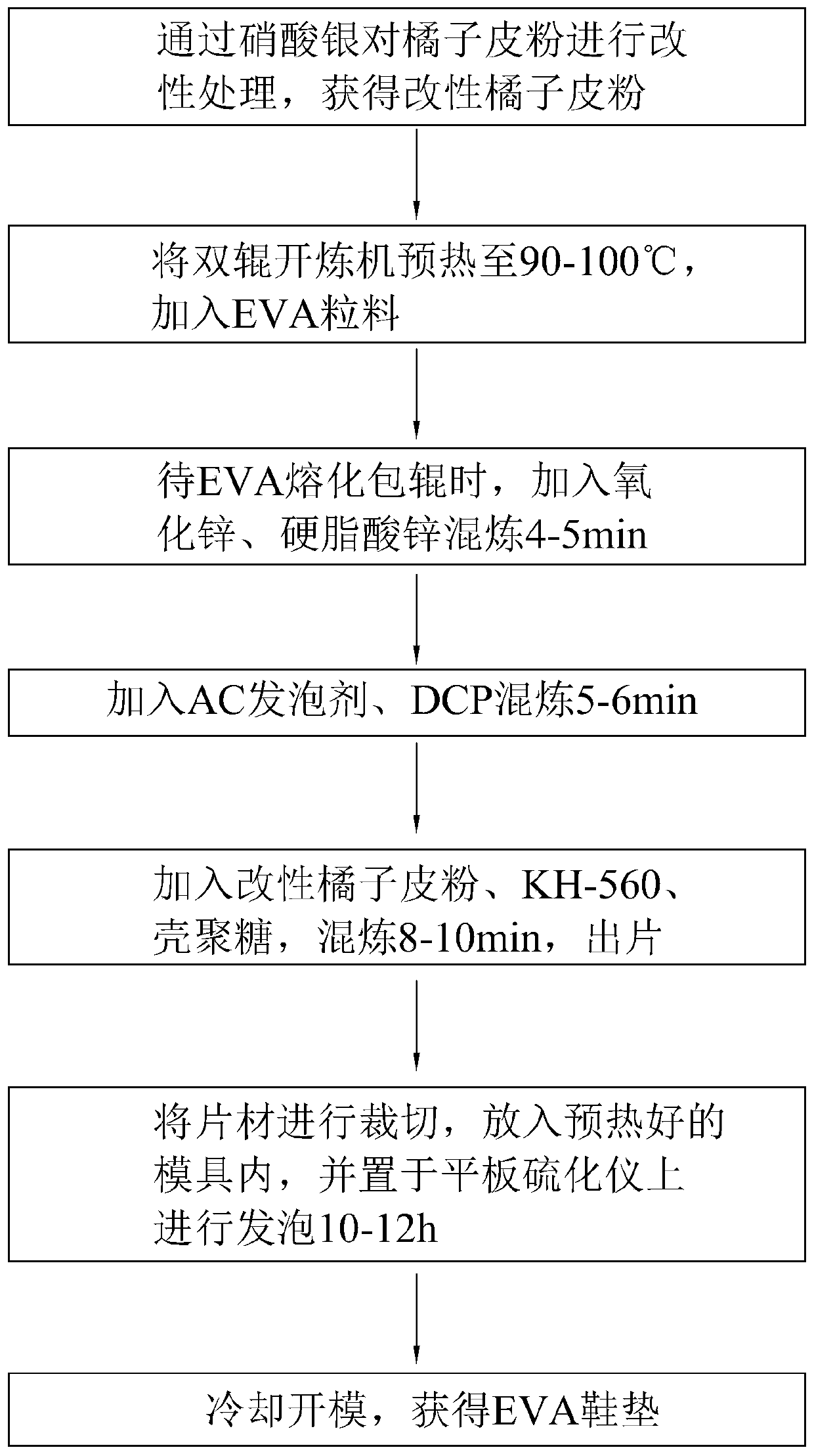

[0052] Such as figure 1 As shown, the preparation method of the EVA insole includes the following steps:

[0053] S1: Take fresh orange peels and wash them, dry them in the sun and dry them in a blast drying oven, crush them with a grinder and pass through a 45-mesh sieve to obtain orange peel powder, mix the grapefruit peel powder and silver nitrate with water and mix well , Put it into a blast drying box and dry to obtain modified orange peel powder;

[0054] S2, preheat the double-roll mill to 90-100°C, and add EVA pellets;

[0055] S3, when the EVA is melted, add zinc oxide and zinc stearate and mix for 4-5 minutes;

[0056] S4, add AC blowing agent and DCP and mix for 5-6min;

[0057] S5, add modified orange peel powder, KH-560, chitosan, mix for 8-10 minutes, and then produce slices;

[0058] S6, cut the sheet, put it into a preheated mold, and place it on a flat vulcanizer,...

Embodiment 2

[0061] An EVA insole, calculated in parts by weight, and its raw material components are shown in Table 1.

[0062] The preparation method of the EVA insole includes the following steps:

[0063] S1: Take fresh orange peels and wash them, dry them in the sun and dry them in a blast drying oven, crush them with a grinder and pass through a 45-mesh sieve to obtain orange peel powder, mix the grapefruit peel powder and silver nitrate with water and mix well , Put it into a blast drying box and dry to obtain modified orange peel powder;

[0064] S2, preheat the double-roll mill to 90-100°C, and add EVA pellets;

[0065] S3, when the EVA is melted, add zinc oxide and zinc stearate and mix for 4-5 minutes;

[0066] S4, add AC blowing agent and DCP and mix for 5-6min;

[0067] S5, add modified orange peel powder, KH-560, chitosan, mix for 8-10 minutes, and then produce slices;

[0068] S6, cut the sheet, put it into a preheated mold, and place it on a flat vulcanizer, and foam for 10-12h under ...

Embodiment 3

[0071] An EVA insole, calculated in parts by weight, and its raw material components are shown in Table 1.

[0072] The preparation method of the EVA insole includes the following steps:

[0073] S1: Take fresh orange peels and wash them, dry them in the sun and dry them in a blast drying oven, crush them with a grinder and pass through a 45-mesh sieve to obtain orange peel powder, mix the grapefruit peel powder and silver nitrate with water and mix well , Put it into a blast drying box and dry to obtain modified orange peel powder;

[0074] S2, preheat the double-roll mill to 90-100°C, and add EVA pellets;

[0075] S3, when the EVA is melted, add zinc oxide and zinc stearate and mix for 4-5 minutes;

[0076] S4, add AC blowing agent and DCP and mix for 5-6min;

[0077] S5, add modified orange peel powder, KH-560, chitosan, mix for 8-10 minutes, and then produce slices;

[0078] S6: Cut the sheet, put it in a preheated mold, and place it on a flat vulcanizer, and foam for 10-12h under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com