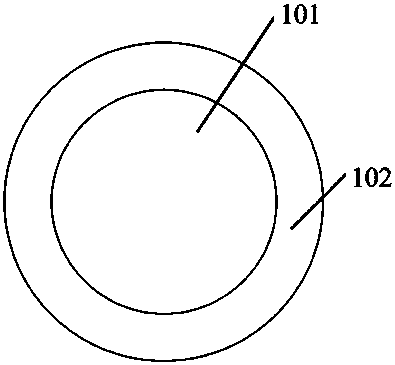

Edge-closed quantum dot enhanced film and preparation method thereof

A technology of quantum dot enhanced film and quantum dot film, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of whitening of the edge of quantum dot film, loss of orange-yellow color, and inability to improve the effect and other issues, to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

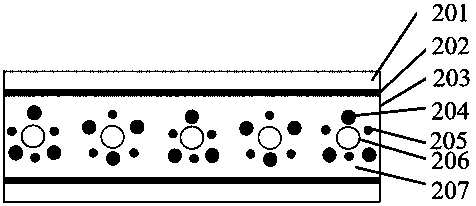

[0046] (1) Preparation of quantum dot film

[0047] Green and red CdSe quantum dots with an average particle size of 3nm and 7nm dissolved in toluene with a mass fraction of 1% were mixed with the matrix resin polyacrylic acid resin and the scattering particles SiO 2 , the photoinitiator 1173 and the diluent acetic acid are mixed together by slit coating and bonded together with the PET base film 201 with the barrier layer 202 , and then subjected to 390nm UV light. At this time, the intermediate glue layer is cured into the quantum dot layer 203 under UV light to form a multi-layer structure with a total thickness of 350 μm, and the thickness of the quantum dot layer is 100 μm.

[0048] (2) Cutting of quantum dot film

[0049] According to the required size, the quantum dot film is cut into the required pattern and punched on the sheet as required.

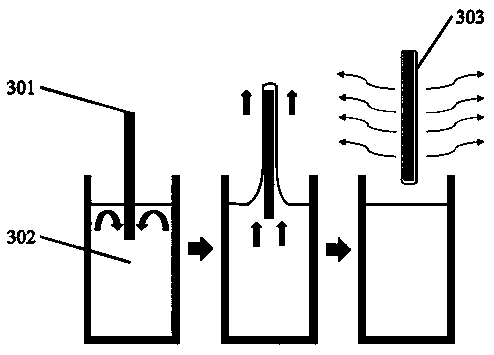

[0050] (3) Wet coating encapsulation of quantum dot film

[0051] After the quantum dot film roll is cut and punched for pos...

Embodiment 2

[0053] Preparation of quantum dot film: the green and red CdSe quantum dots with an average particle size of 3 nm and 7 nm dissolved in n-hexane with a mass fraction of 1% and matrix resin polyacrylic acid resin, scattering particles CaO 2 , the thermal initiator and the diluent toluene are mixed together by slit coating and bonded together with the PET base film 201 with the barrier layer 202 , and then subjected to 390nm UV light. At this time, the intermediate glue layer is cured into the quantum dot layer 203 under UV light to form a multi-layer structure with a total thickness of 350 μm, and the thickness of the quantum dot layer is 100 μm.

Embodiment 3

[0055] Preparation of quantum dot film: the green and red CdSe quantum dots with an average particle size of 3 nm and 7 nm dissolved in isobornyl acrylate with a mass fraction of 1% were mixed with matrix resin polyacrylic acid resin, mercapto resin, and scattering particles TiO 2 , the photoinitiator 1173 and the diluent ethyl acetate are mixed together and bonded together with the PET base film 201 with the barrier layer 202 by slit coating. The total thickness of the barrier layer 202 and the PET base film 201 is 50 μm, and then passes through UV light and 80°C high temperature oven. At this time, the intermediate glue layer is cured into the quantum dot layer 203 under UV light and high temperature to form a multi-layer structure with a total thickness of 200 μm, wherein the thickness of the quantum dot layer is 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com