Injection molding automatic quality testing production line for plastic products

A technology for plastic products and production lines, which is applied in the direction of sorting, etc., to achieve the effect of improving the quality of inspection, fast inspection speed, and simple manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

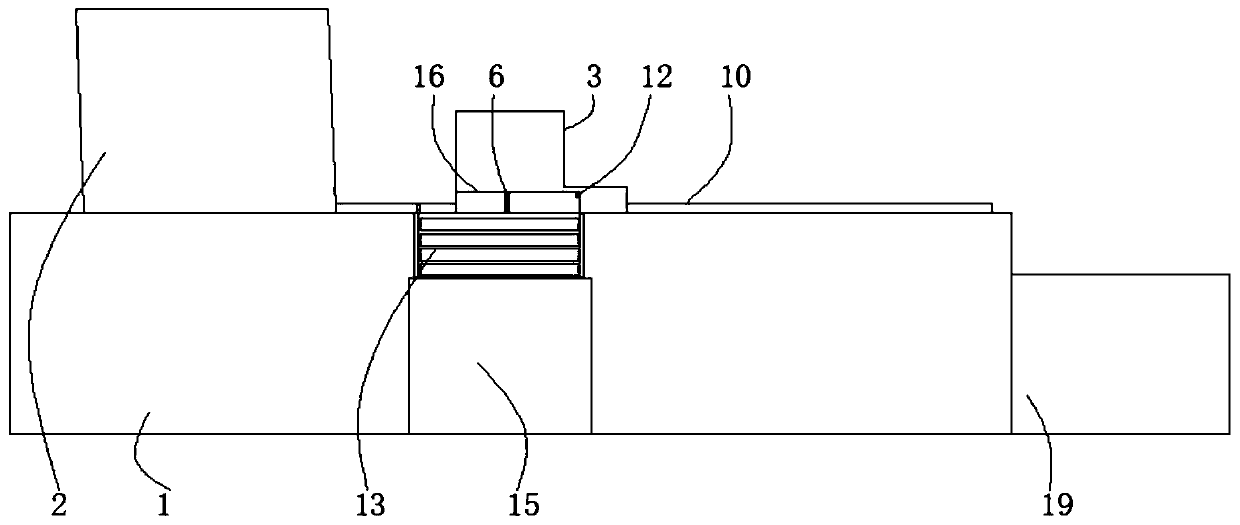

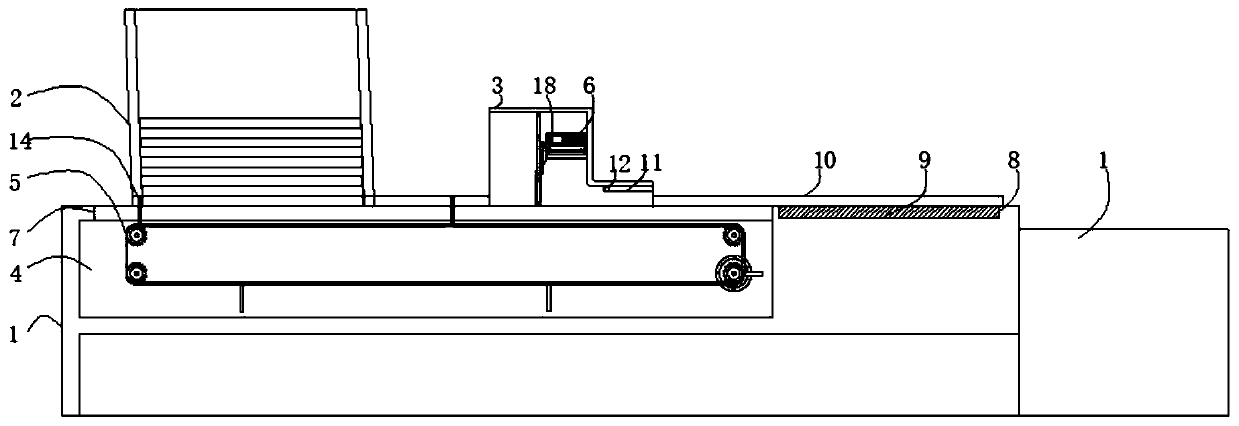

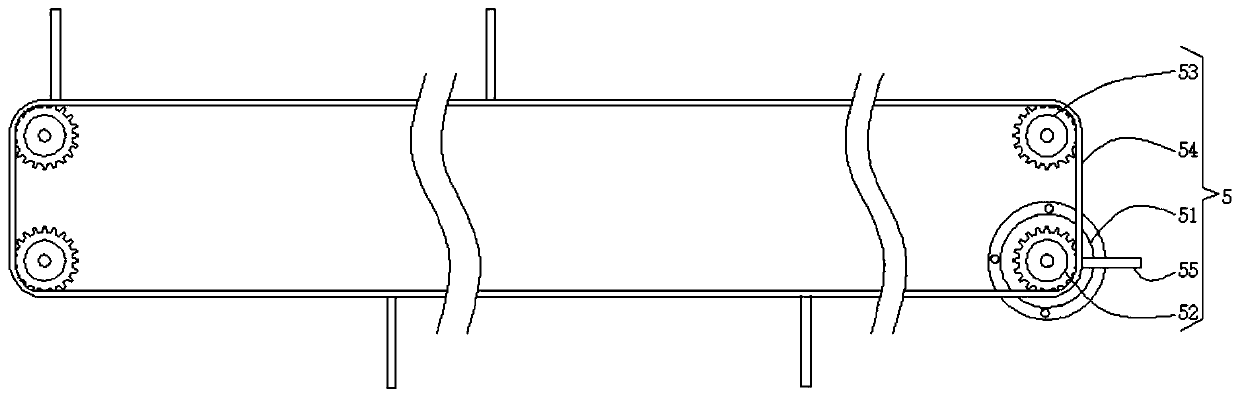

[0029] Please refer to figure 1 , figure 2 , image 3 with Figure 4 ,in, figure 1 A schematic structural diagram of a preferred embodiment of the automatic quality inspection production line for injection molding of plastic products provided by the present invention; figure 2 for figure 1 the sectional view shown; image 3 for figure 1 Schematic diagram of the structure of the feeding assembly shown; Figure 4 for figure 1 Schematic diagram of the structure of the proposed assembly is shown. Automatic quality inspection production line for injection molding of plastic products, including: operation table 1;

[0030] Placement box 2, the placement box 2 is fixed on the left side of the top of the console 1;

[0031] A detection box 3, the detection box 3 is fixed on the top of the console 1 and is located on the right side of the placement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com