A vertical processing machine tool

A processing machine tool and vertical technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of spindle rotation and other problems, and achieve the effect of ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

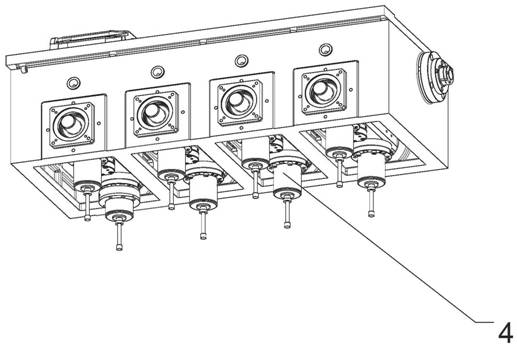

[0022] like Figure 3-5 As shown in the figure, a vertical processing machine tool includes a bed 5 and a Z-axis slide table 1. Two upright columns 2 are fixedly connected to the bed body. The upright column 2 is provided with a Z-axis slide rail 3, and both ends of the Z-axis slide table 1 are connected to The Z-axis slide rails 3 are slidably connected, and a main shaft 4 is arranged in the middle of the Z-axis slide table 1 , and the main shaft 4 is located below the Z-axis slide table 1 . The column 2 is fixedly connected with the bed 5, the relative movement of the workpiece and the main shaft 4 in the horizontal direction is realized by the relative movement of the worktable and the main shaft 4, and the relative movement of the workpiece and the main shaft 4 in the vertical direction is achieved by the movement of the Z-axis slide table 1 Realization, when the Z-axis slide table 1 moves, there is horizontal movement in addition to the vertical movement, and the worktabl...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that the angle between the Z-axis slide rail 3 and the horizontal plane is 30°, the Z-axis slide rail 3 is located on the top surface of the column 2, and the angle between the top surface of the column 2 and the horizontal plane is 30° °. The Z-axis slide rail 3 is perpendicular to the Y-axis slide rail 8 . When the Z-axis slide table 1 moves along the Z-axis slide rail 3 , the X-axis slide table 7 needs to be moved along the X-axis slide rail 9 to eliminate the influence.

Embodiment 3

[0029] The difference between this embodiment and Embodiment 1 is that the angle between the Z-axis slide rail 3 and the horizontal plane is 60°, the Z-axis slide rail 3 is located on the top surface of the column 2, and the angle between the top surface of the column 2 and the horizontal plane is 50° °. At this time, there is a certain angle between the orthographic projection of the Z-axis slide rail 3 on the top surface of the bed 5 and the Y-axis slide rail 8 and the X-axis slide rail 9 . When the Z-axis slide 1 moves along the Z-axis slide 3, the X-axis slide 7 needs to move along the X-axis slide 9, and the Y-axis slide 6 moves along the Y-axis slide 8 to eliminate the Z-axis slide 1 from moving Impact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com