Platform bidding machine for radio frequency coal quality online monitoring and detection calibration device

A coal quality and radio frequency technology, applied in the direction of cooperative operation devices, automatic test and analysis mark record carriers, computer components, etc., can solve the problems of poor environment in the coal conveyor belt, and achieve long-term continuous operation, The effect of reducing the steps of replacing the silo and controlling the quantity of bids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The platform bidding machine and detection and calibration device for radio frequency coal quality online monitoring involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0030]

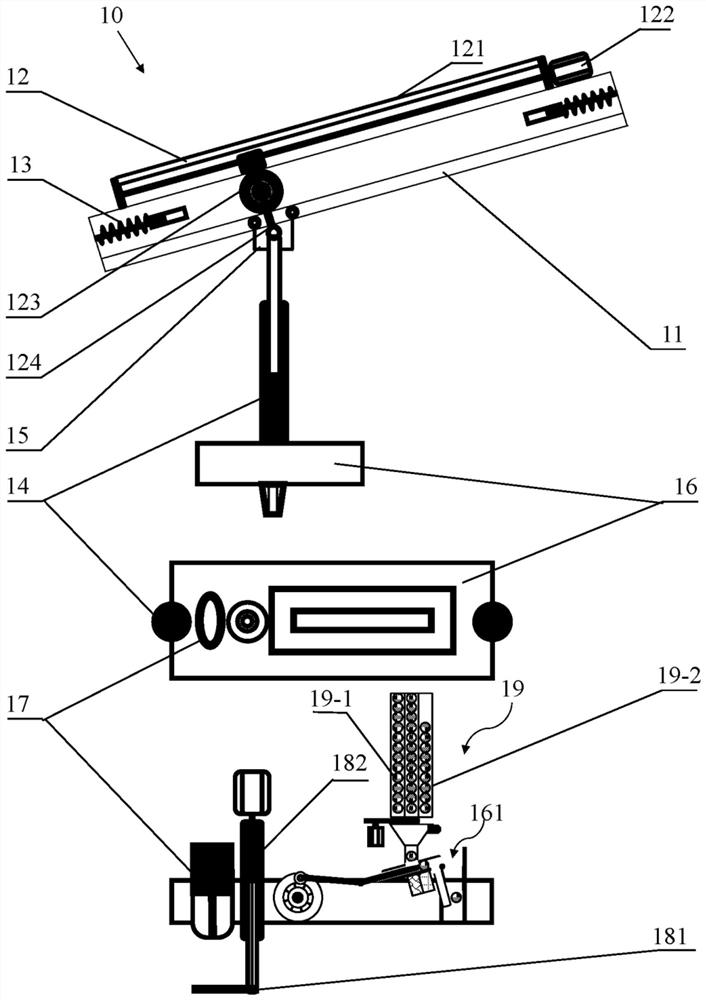

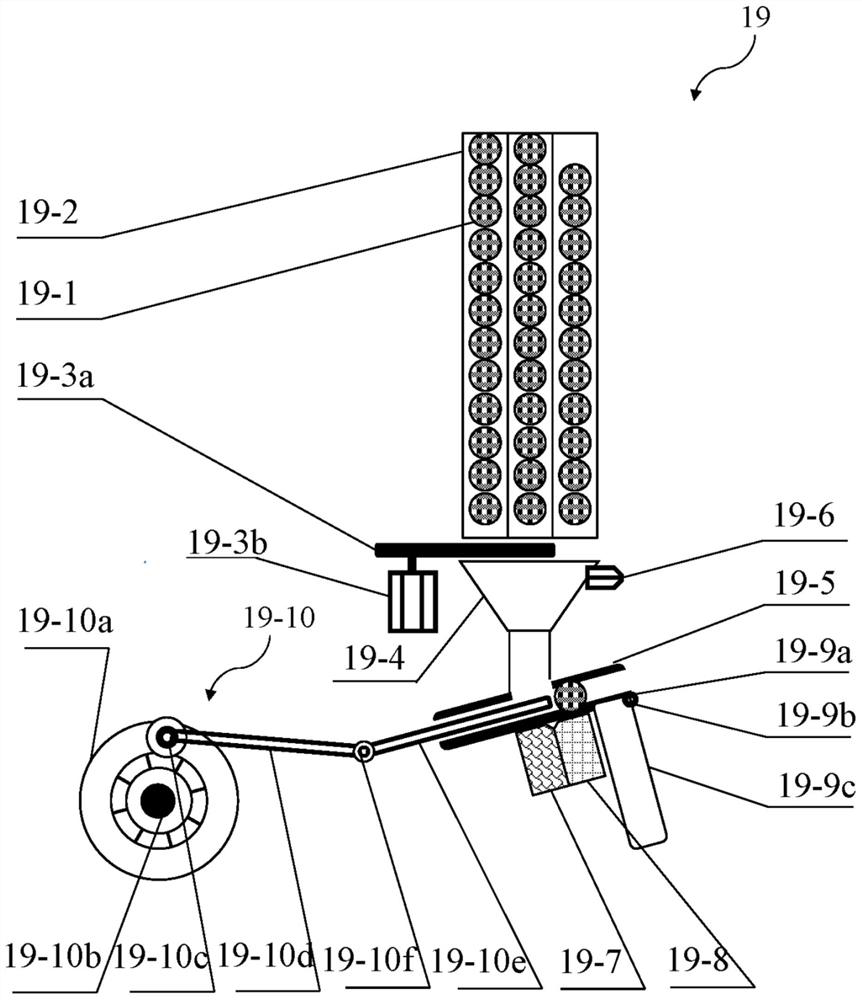

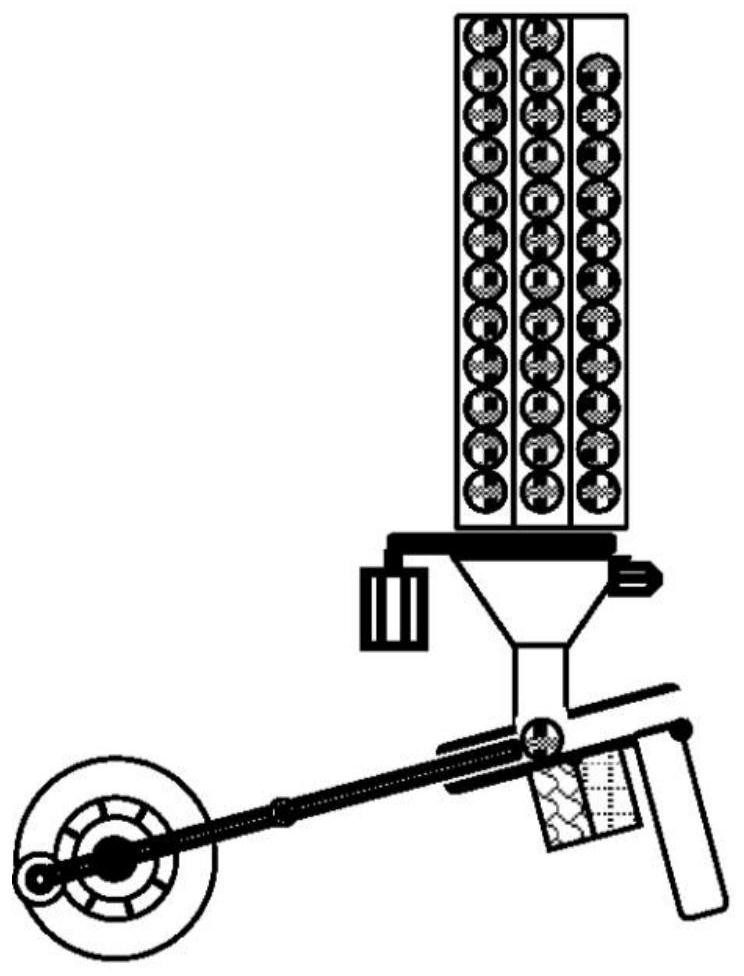

[0031] Such as figure 1 As shown, the coal quality detection and calibration device 10 includes a linear slide rail 11, a moving part 12, a protection part 13, a connecting column 14, a vertical limit part 15, an anti-collision platform 16, a height regulator, a detection probe 17, and a flattening part 18 , platform bidding machine 19 and controller.

[0032] Linear slide rail 11 is arranged on the coal conveyer belt top, and inclination is identical with coal conveyer belt.

[0033] The moving part 12 reciprocates along the linear slide rail 11, and the moving speed along the coal conveying direction is consistent with that of the coal conveying belt. The moving part 12 includes a displacement slide 121 , a stepping motor 122 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com