Preparation method of palatable flavor enzymolysis fermentation wet feed for feed

A flavor enzyme, wet feed technology, applied in the field of feed, enzyme preparations and microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

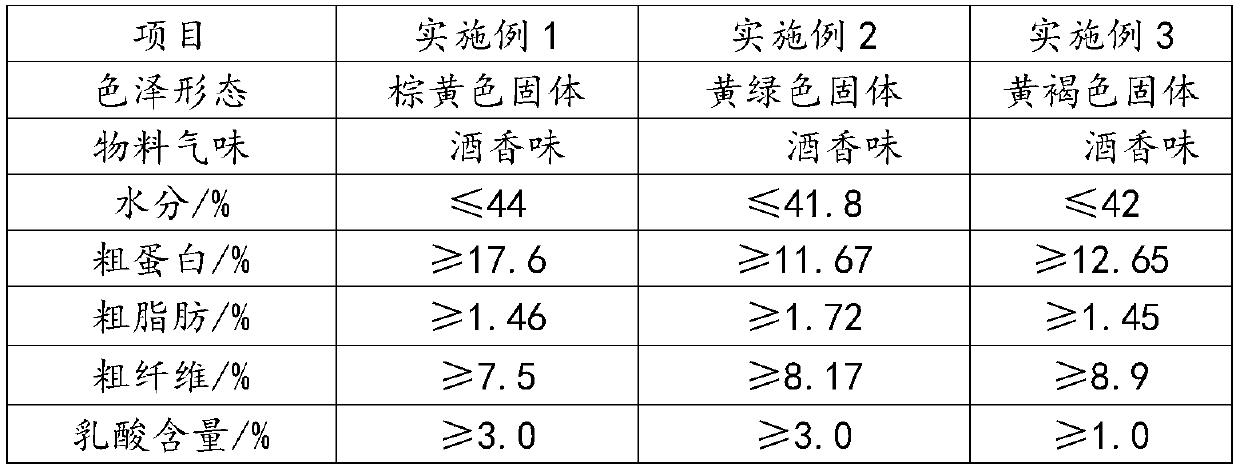

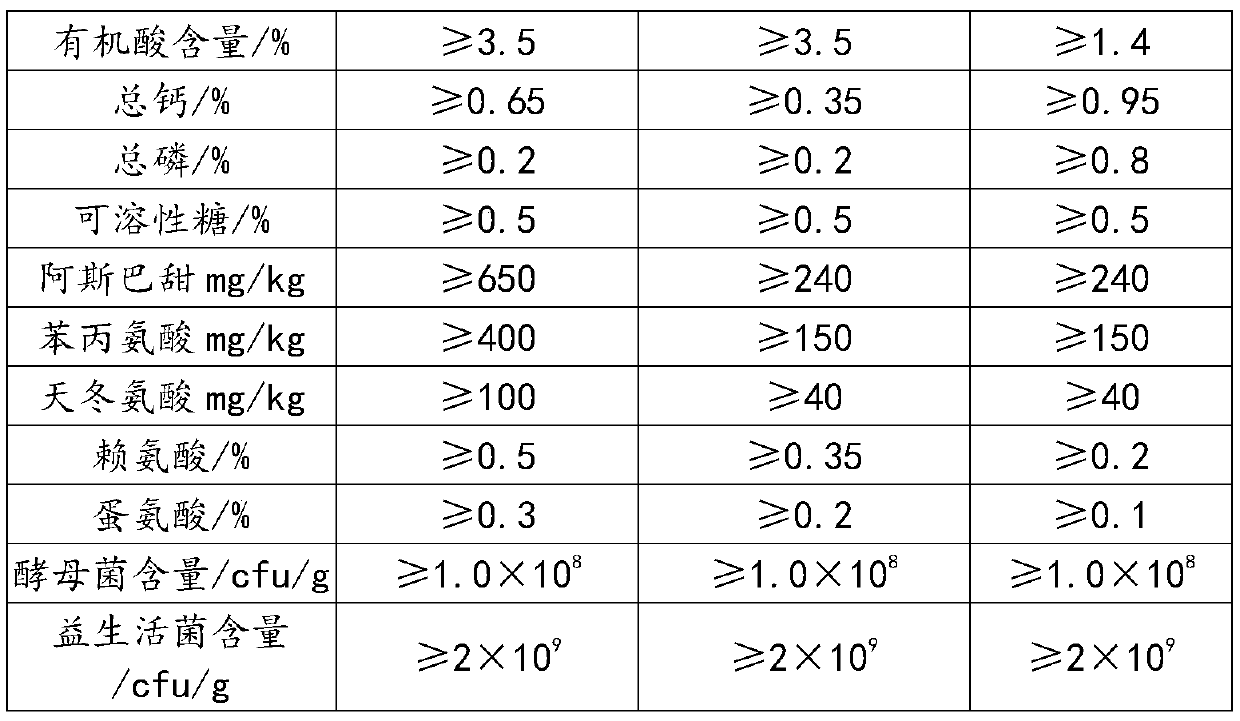

Examples

Embodiment 1

[0147] Step 1: Preparation of lactic acid bacteria seed solution

[0148] Add 3000g of glucose, 1000g of dry corn steep powder, 500g of beef extract, 1000g of yeast extract, 500g of sodium chloride, 200g of potassium dihydrogen phosphate, 60g of magnesium sulfate, and 25g of manganese sulfate into the seed tank. After being sterilized in minutes, cool to the culture temperature, insert the strains of lactic acid bacteria in shake flasks, and perform anaerobic culture for 24 hours to obtain 60 kg of Lactobacillus plantarum bacterial liquid, 10 kg of Lactococcus bacterial liquid, and 30 kg of Lactobacillus thermophilic bacterial liquid.

[0149] Step 2: Yeast seed liquid preparation:

[0150] Add 50g of yeast extract, 100g of peptone, 100g of glucose and 25g of sodium chloride to the seed tank, add water to make up to 5L, adjust the pH to 6.9-7.1, sterilize at 121°C for 30 minutes, cool to the culture temperature, and insert yeast Bacteria strains were cultured aerobically for ...

Embodiment 2

[0166] Step 1: Preparation of lactic acid bacteria seed solution

[0167] Add 4200g of glucose, 1400g of dry corn steep powder, 700g of beef extract, 1400g of yeast extract, 700g of sodium chloride, 280g of potassium dihydrogen phosphate, 84g of magnesium sulfate, and 35g of manganese sulfate into the seed tank. Cool to culture temperature after minute sterilization, insert lactic acid bacteria shake flask bacterial classification, anaerobic culture 24 hours, make Lactobacillus plantarum bacterial liquid 50kg, Lactococcus bacterial liquid 50kg, thermophilic Lactobacillus bacterial liquid 40kg.

[0168] Step 2: Yeast seed liquid preparation:

[0169] Add 50g of yeast extract, 100g of peptone, 100g of glucose and 25g of sodium chloride to the seed tank, add water to make up to 5L, adjust the pH to 6.9-7.1, sterilize at 121°C for 30 minutes, cool to the culture temperature, and insert yeast Bacteria strains were cultured aerobically for 24 hours to obtain 4 kg of baker's yeast see...

Embodiment 3

[0185] Step 1: Preparation of lactic acid bacteria seed solution

[0186] Add 1050g of glucose, 350g of dry corn steep powder, 175g of beef extract, 350g of yeast extract, 175g of sodium chloride, 70g of potassium dihydrogen phosphate, 21g of magnesium sulfate, and 8.75g of manganese sulfate into the seed tank. After sterilizing for 30 minutes, cool to the culture temperature, insert lactic acid bacteria strains in shake flasks, and perform anaerobic culture for 24 hours to obtain 20 kg of Lactobacillus plantarum and 15 kg of Lactobacillus thermophiles.

[0187] Step 2: Yeast seed liquid preparation:

[0188] Add 100g of yeast extract, 200g of peptone, 200g of glucose and 50g of sodium chloride to the seed tank, add water to make up to 10L, adjust the pH to 6.9-7.1, sterilize at 121°C for 30 minutes, cool to the culture temperature, and insert yeast Bacteria strains were cultured aerobically for 24 hours to obtain 2 kg of baker's yeast seed liquid and 8 kg of high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com