Device for detecting inner wall defects of cylinder

A technology for detecting pillars and defects, applied in telescopes, optics, instruments, etc., can solve problems such as low efficiency, speckle, and large manpower, and achieve the effects of improving automation, increasing light brightness, and strong adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

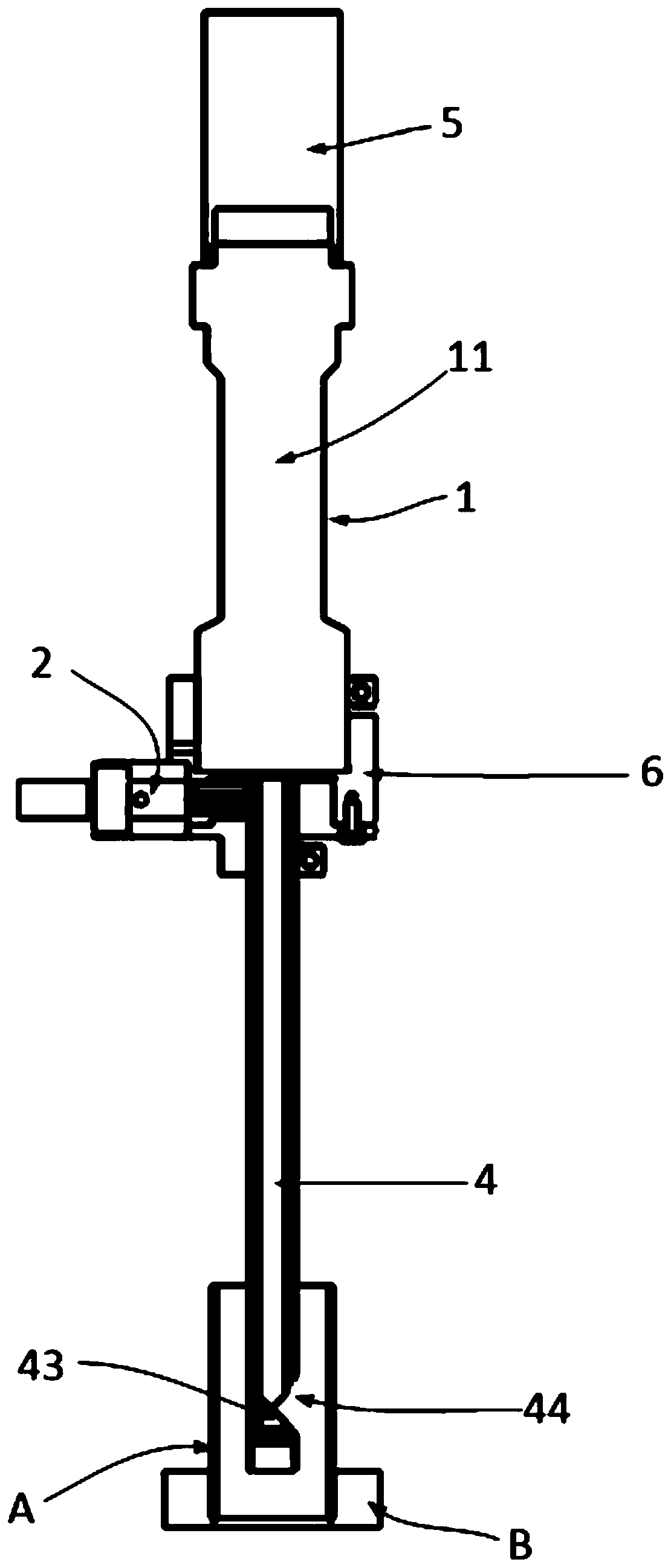

[0049] This embodiment provides a device for detecting defects on the inner wall of a column, such as Figure 1-3 shown, including:

[0050] The lens 1 has a channel 11 inside to allow light to pass through;

[0051] light source 2;

[0052] Probe tube 4, one end is connected to one end of described lens 1, and the inside of the other end is provided with light deflection assembly 43, and described probe tube 4 is provided with opening 44 at the place that aligns with described light deflection assembly 43; The light outside the tube 4 can enter the inside through the opening 44 and pass through the light deflecting assembly 43 and then transmit along the axial direction of the channel 11;

[0053] An optical fiber 3, the optical fiber 3 is arranged in the probe tube 4, one end is connected to the light source 2, and the other end is exposed from the edge of the opening 44 of the probe tube 4, so that the light emitted by the light source 2 can travel along the The optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com