Cable life prediction method based on leakage current difference coefficient

A technology of leakage current testing and leakage current, applied in the direction of measuring current/voltage, measuring only current, measuring electricity, etc., can solve problems such as threatening the safe operation of the power grid, accelerating cable insulation aging, air gap, etc., and avoiding cable insulation breakdown The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with flowchart, the present invention will be further described:

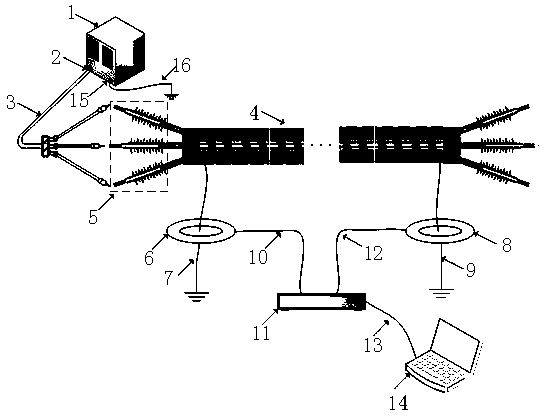

[0043] according to figure 1 Cable leakage current test platform wiring diagram, the specific calculation steps of the present invention are as follows:

[0044] Step 1: Build a cable leakage current test platform

[0045] Connect the No. 1 port 2 of the high-frequency voltage source (1) to the terminal 5 of the test cable 4 through the high-voltage test line 3, put the No. 1 high-frequency current transformer 6 into the No. 1 grounding wire 7 of the test cable 4, and connect the 2 No. 2 high-frequency current transformer 8 is inserted into No. 2 ground wire 9 of test cable 4, No. 1 high-frequency current transformer 6 is connected to data collector 11 through No. 1 signal transmission line 10, No. 2 high-frequency current transformer 8 Connect the data collector 11 with the No. 2 signal transmission line 12, connect the data collector 11 with the upper computer 14 through the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com