Adjustable flange and smoke dust instrument applying compatibility of adjustable flange

A technology for adjusting flanges and smoke and dust meters. It is used in instruments, scientific instruments, measuring devices, etc. It can solve the problems of distortion, lack of dust data, and difficulty in reducing procurement costs, and achieve the effects of reducing storage costs, improving quality, and quick replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

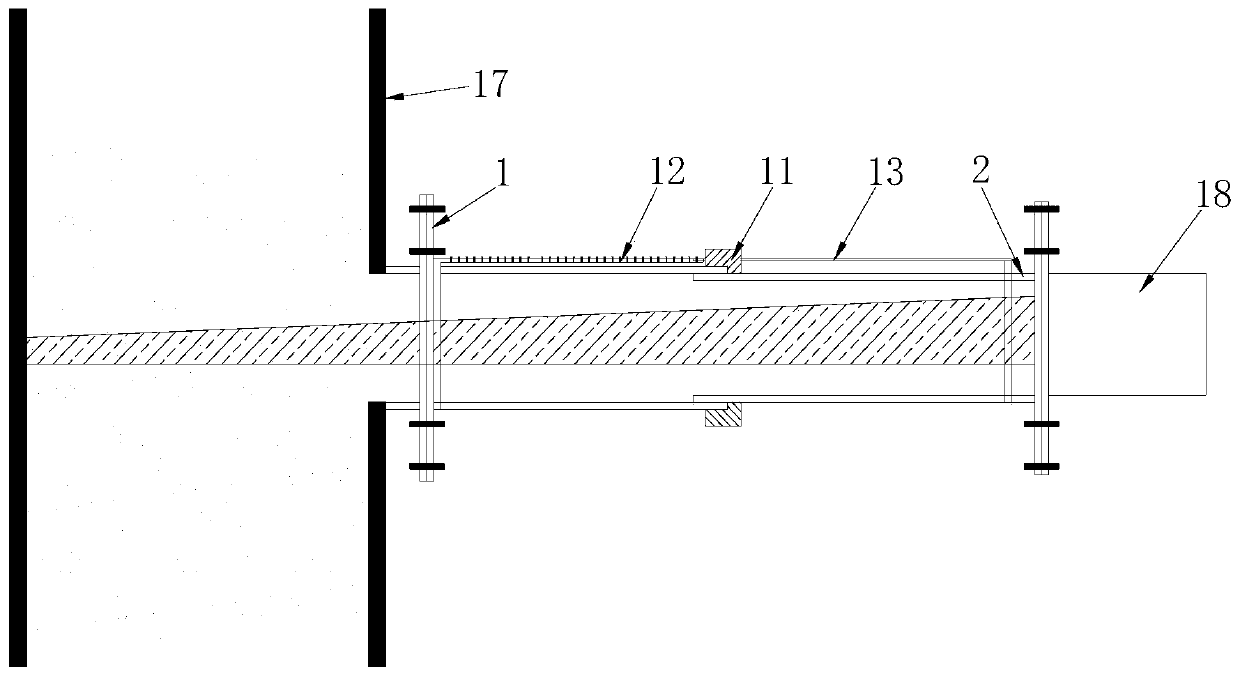

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

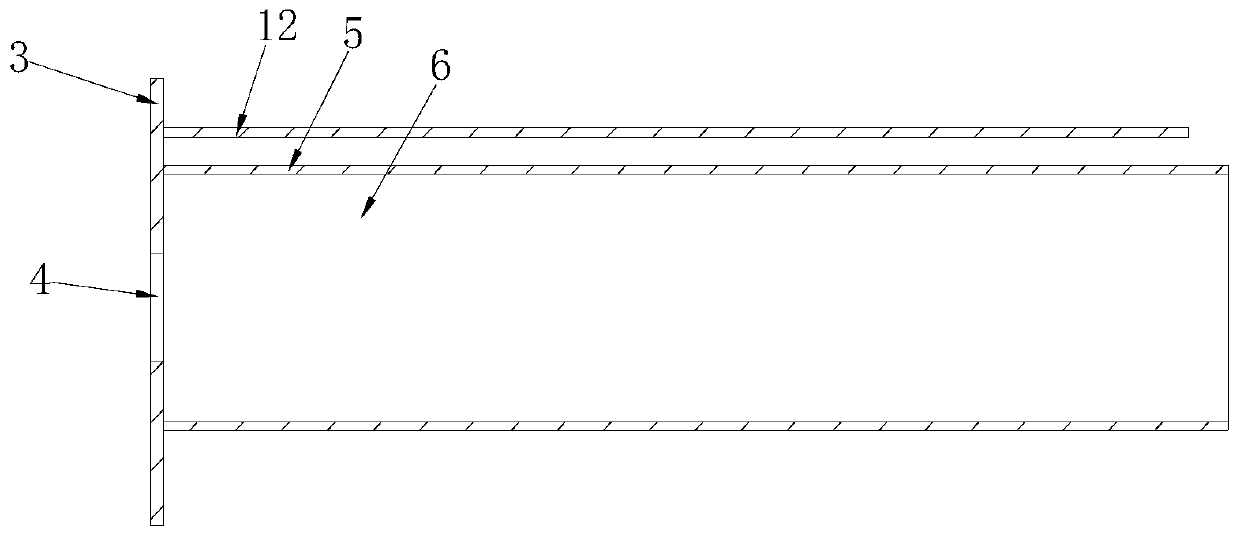

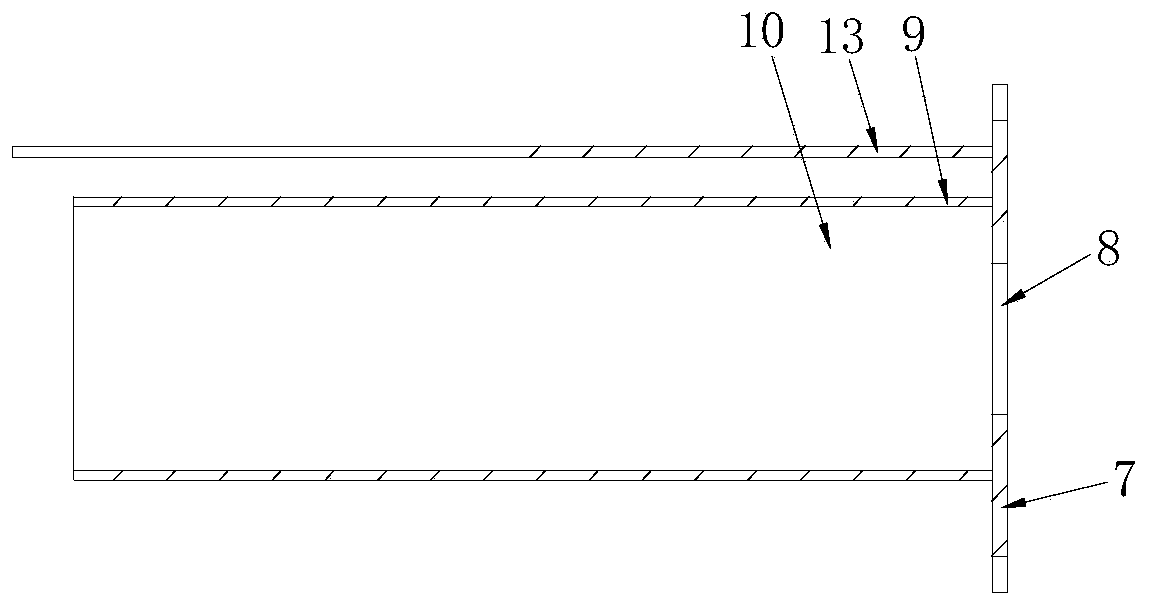

[0027] like Figure 1~5 The adjustable flange shown includes the first flange 1 that can be connected to the flue 17 and the second flange 2 that can be connected to the smoke meter 18, based on the high-temperature acidic or high-temperature alkaline working conditions on site , the first flange part 1 and the second flange part 2 can be made of corrosion-resistant stainless steel, wherein,

[0028] The first flange 1 is provided with a first connecting portion 3 that can be connected to the flue 17, and the first connecting portion 3 is provided with a first optical path hole 4 that can be connected to the flue 17. The first connection The part 3 is provided with a first extension part 5 extending toward the second flange part 2 along the axial direction of the first optical path hole 4, and the first extension part 5 is provided with a first passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com