Test device and application method for supporting force of fluid-filled lining structure in simulated tunnel surrounding rock subsidence process

A testing device and fluid technology, applied in measuring devices, using repetitive force/pulse force to test the strength of materials, and using stable tension/pressure to test the strength of materials, etc. Problems such as the stress characteristics of the surrounding rock intrusion of the lining support structure to achieve the effect of uniform stress and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

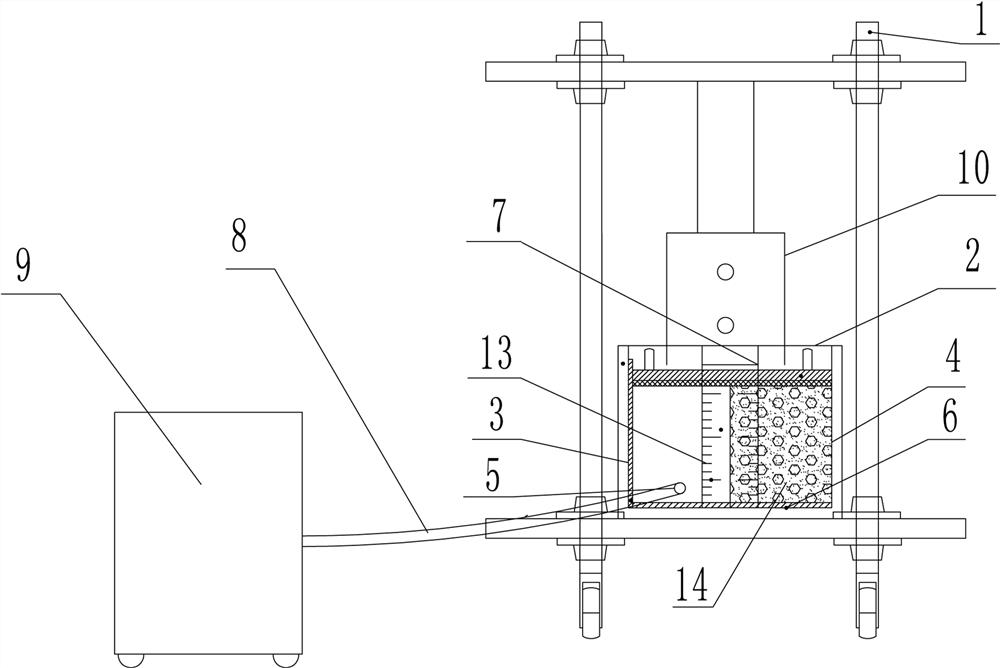

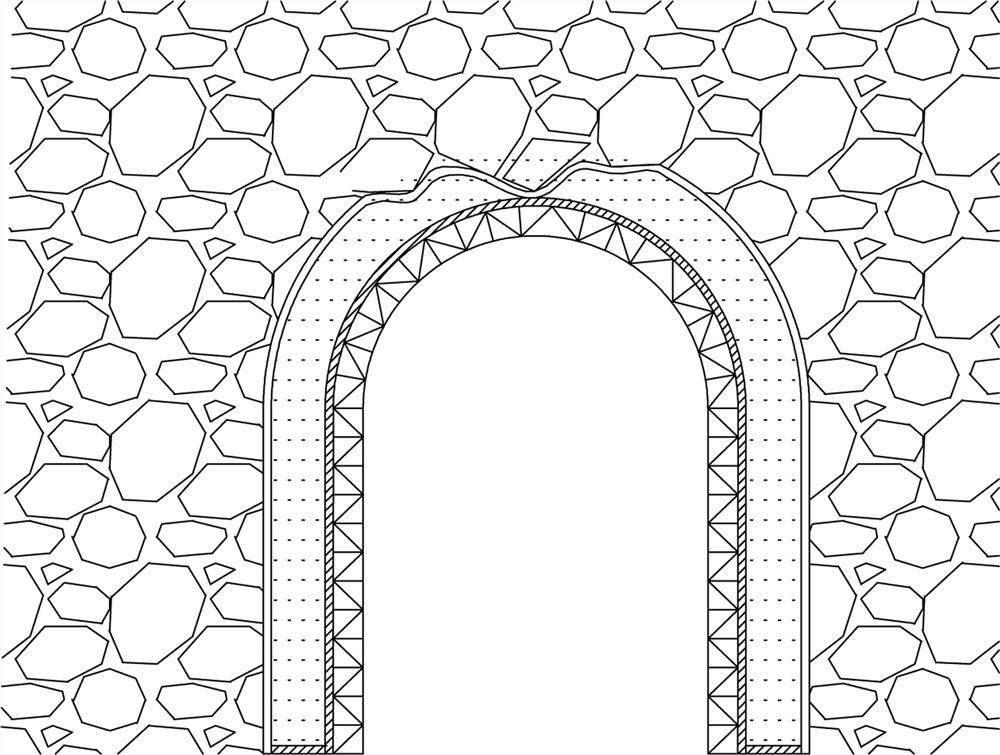

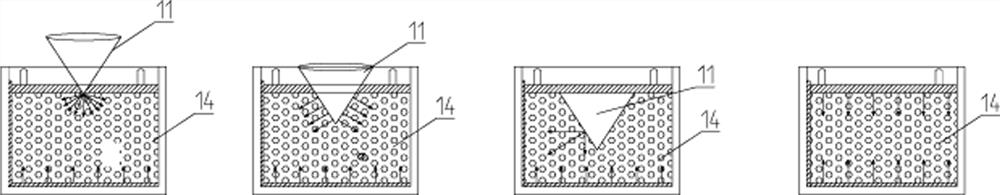

[0037] Such as Figure 1-Figure 5 As shown, a test device for supporting force of fluid-filled lining structures in the process of simulating the tunnel surrounding rock subsidence, it includes a frame 1, the bottom plate of the frame 1 is connected with a visible side limit box 2, and the side surface of the visible side limit box 2 is provided with The fixed end 3 and the pressure relief port 5; the side panel of the visible lateral limit box 2 is tempered glass 4, and the surface of the tempered glass 4 is provided with a scale 13; the bottom and the side wall of the visible lateral limit box 2 are provided with a columnar pressure sensor 76; the frame 1. A jack is connected under the top plate, and a columnar pressure sensor is arranged directly under the jack. By adopting the above-mentioned device, the problems of simulation distortion and inconvenient simulation operation are effectively solved, so that the force deformation of the tunnel surrounding rock can be truly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com