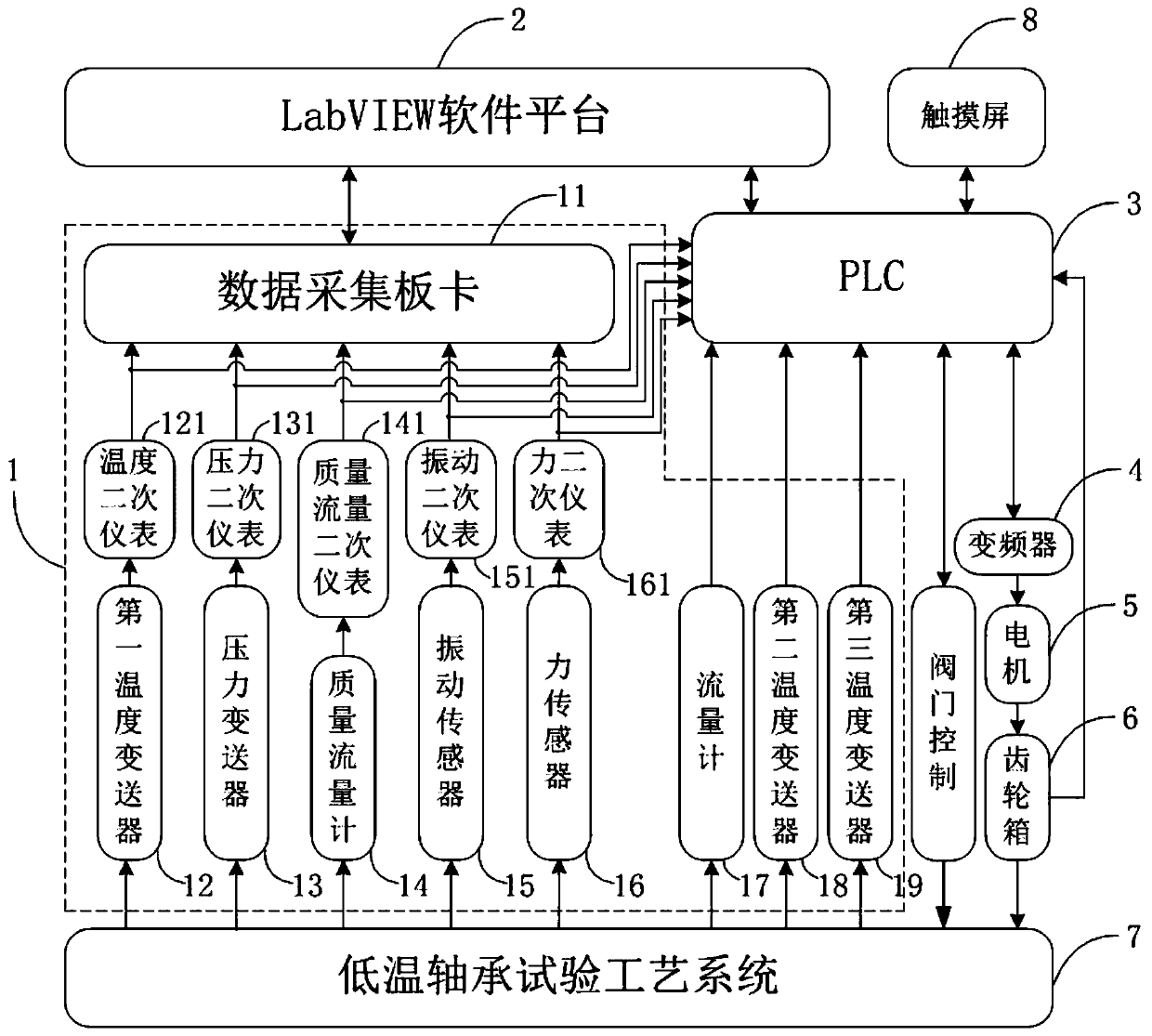

Low-temperature bearing test measurement and control system

A low-temperature bearing, measurement and control system technology, applied in the field of measurement and control, can solve problems such as reducing the accuracy and safety of low-temperature bearing test results, affecting program readability, maintaining program response speed, and outdated software versions, and achieving readability. and maintainability, high measurement accuracy and accuracy, and easy to master effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the purposes, technical solutions and advantages of the embodiments of the present application clearer, the following will clearly illustrate the spirit of the content disclosed in the application with the accompanying drawings and detailed descriptions. After any person skilled in the art understands the embodiments of the content of the application , when it can be changed and modified by the technology taught in the content of the application, it does not depart from the spirit and scope of the content of the application.

[0070] The exemplary embodiments and descriptions of the present application are used to explain the present application, but not to limit the present application. In addition, elements / members with the same or similar numbers used in the drawings and embodiments are used to represent the same or similar parts.

[0071] The terms "first", "second", ... etc. used herein do not specifically refer to a sequence or order, nor are they...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com