Parameter measuring device and method for large cylindrical workpiece

A technology of parameter measurement and measurement method, which is applied to measurement devices, mechanical measurement devices, and optical devices, etc., can solve the problems of measuring instrument manufacturing errors and reduce measurement accuracy, and achieve improved calculation accuracy, stable speed control, and high calculation accuracy. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following, with reference to the drawings, through the description of the embodiments, the specific implementation of the present invention such as the shape and structure of the various components involved, the mutual position and connection relationship between the various parts, the function and working principle of each part, and the manufacturing process And the operation and use method, etc., are described in further detail to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical scheme of the present invention.

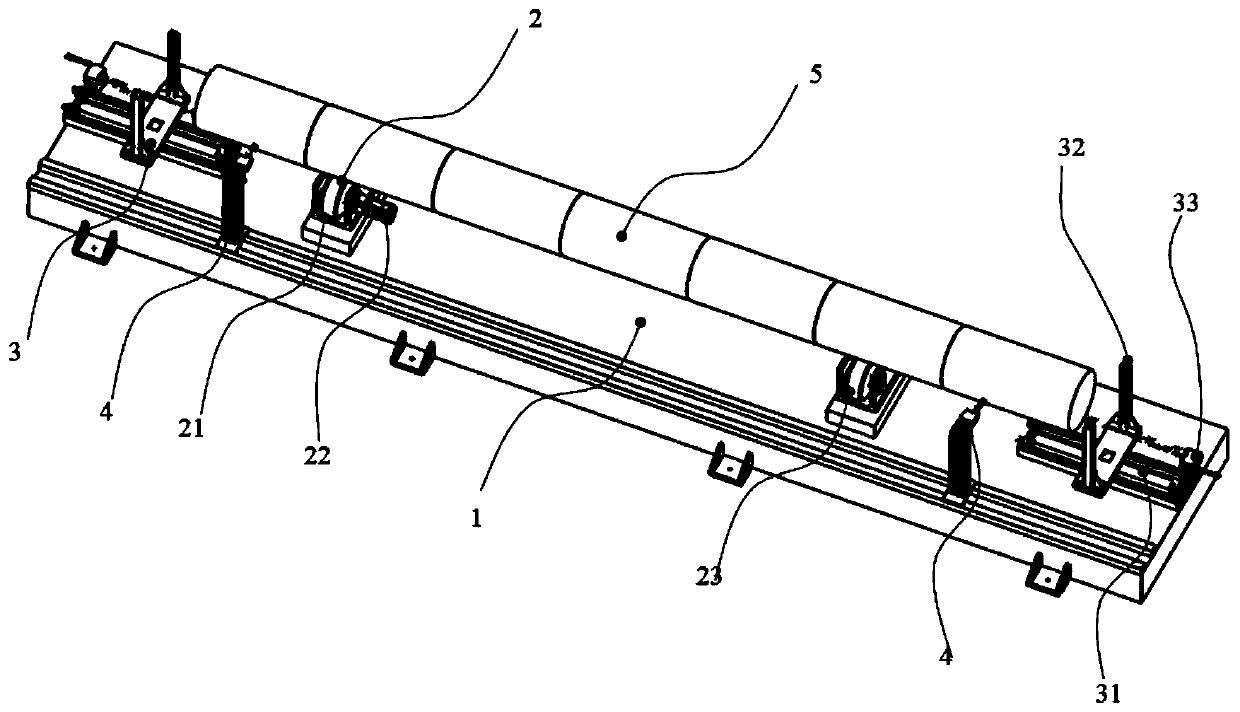

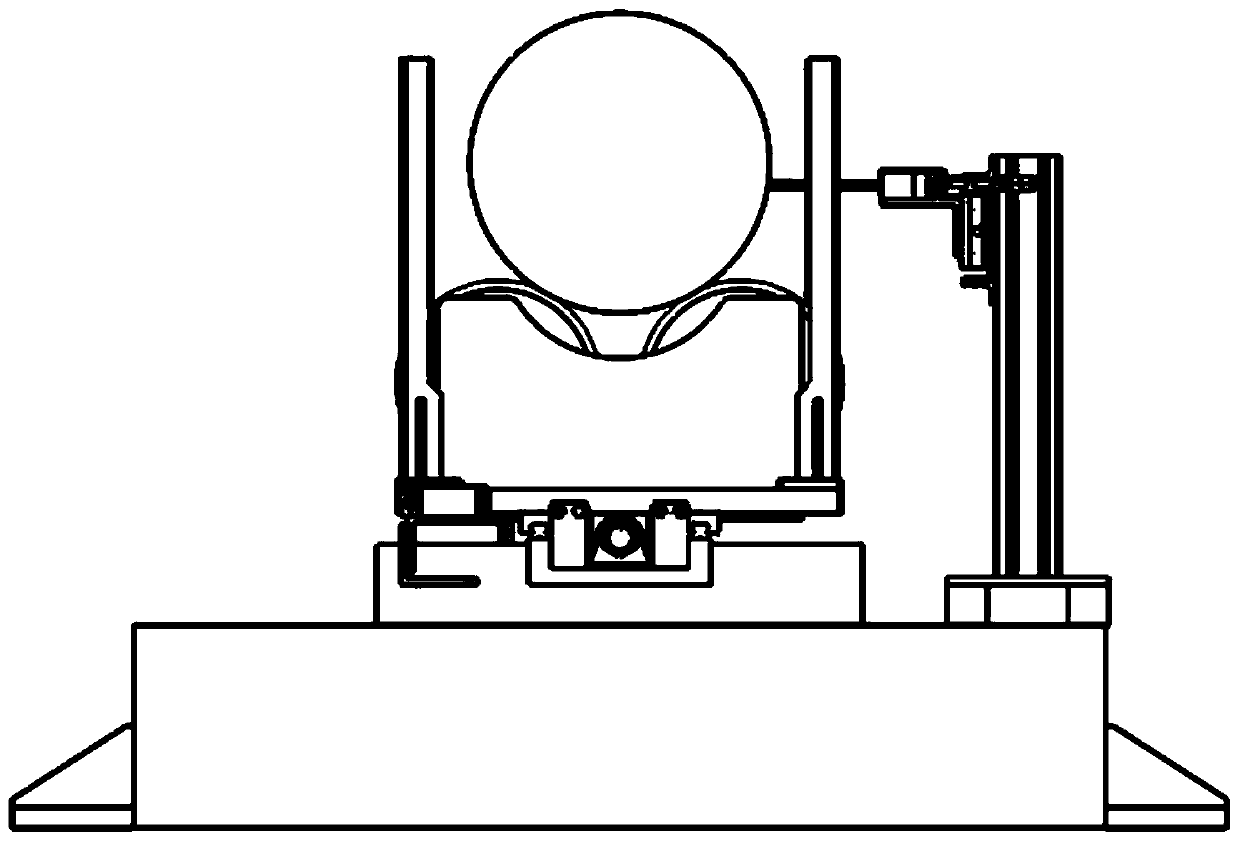

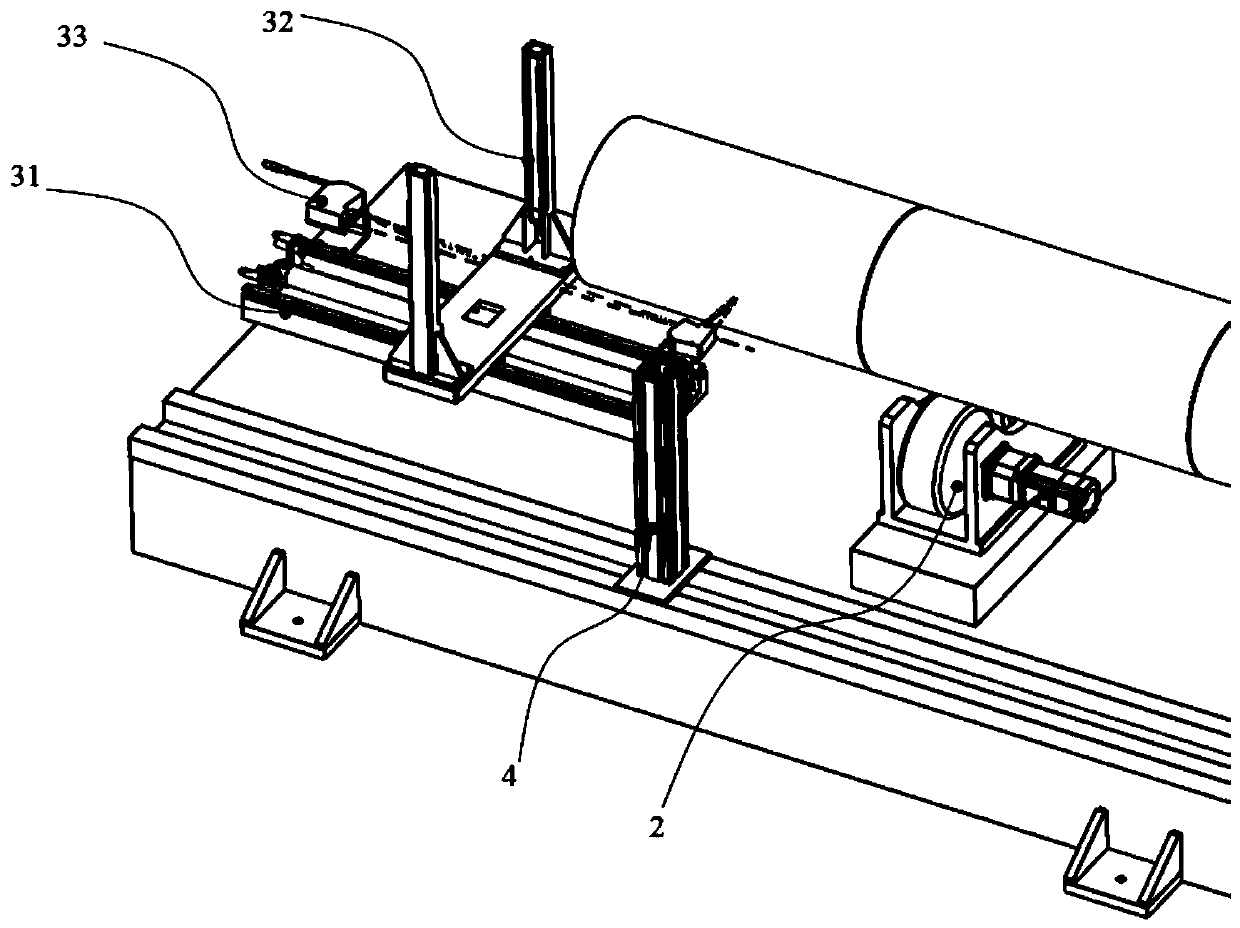

[0037] The parameter measuring device for the large cylindrical workpiece 5 is mainly composed of the measuring device base 1, the supporting rotating mechanism 2, the length measuring mechanism 3, and the circumferential runout measuring mechanism 4.

[0038] The measuring device mainly includes the following parts:

[0039] Base 1: Base 1 is the carrying mechanism of the entire me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com