Cotton drying machine

A drying machine and cotton technology, applied in the textile field, can solve the problems of short residence time of cotton, incomplete drying of cotton, and inability to guarantee the drying quality of cotton, and achieve the effect of improving drying efficiency and improving cotton quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

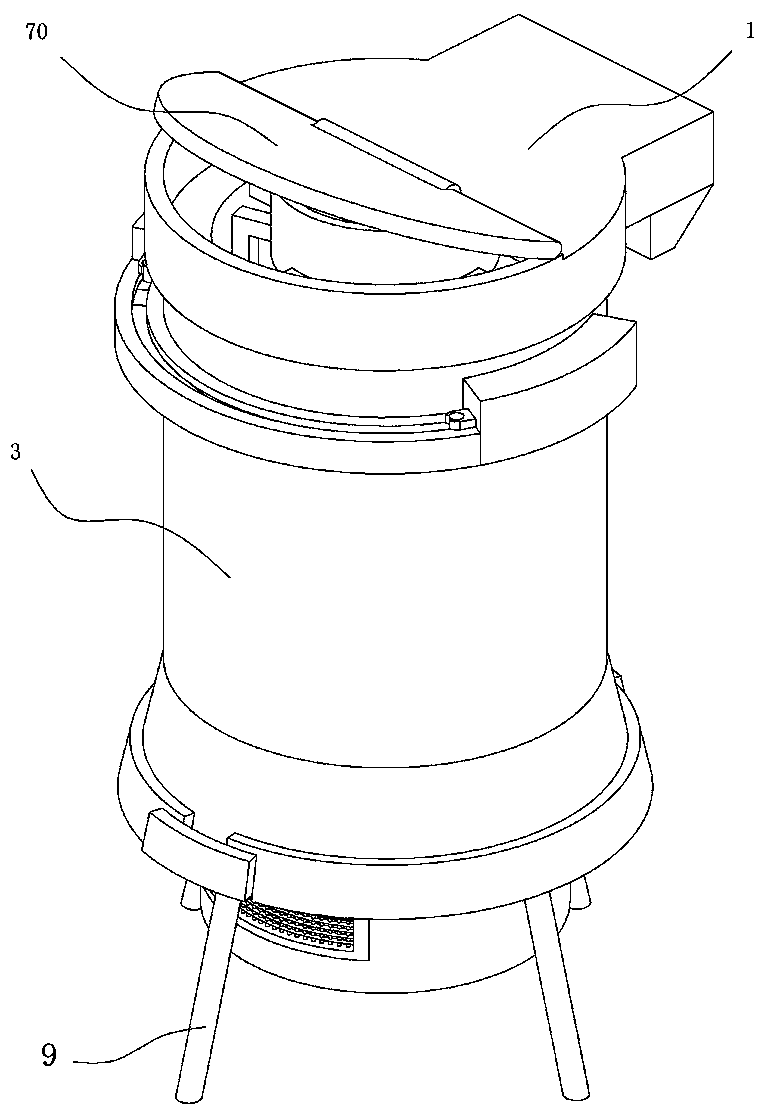

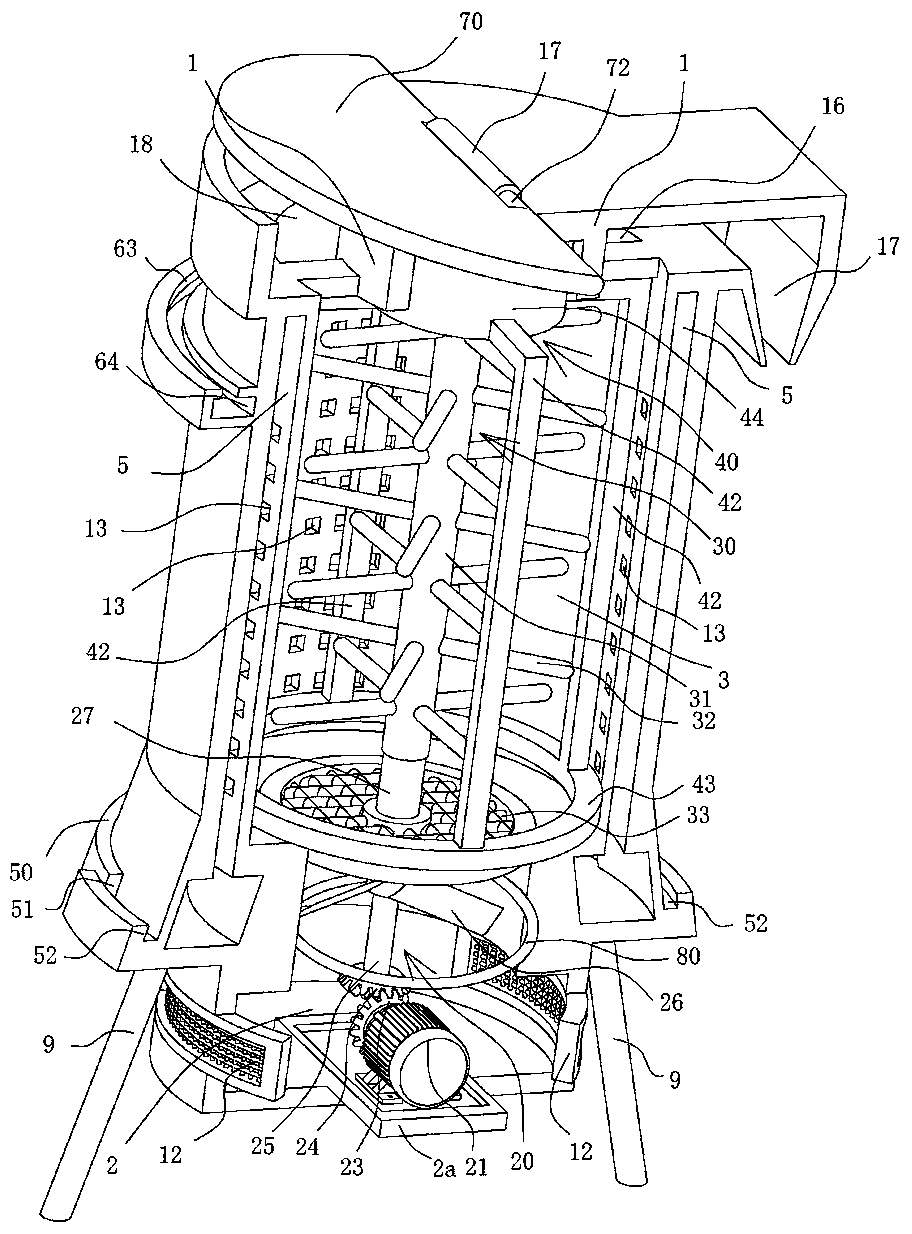

[0028] Such as Figure 1 to Figure 7 As shown, the cotton dryer of the present invention includes a chassis 1, and four evenly distributed legs 9 are arranged under the chassis 1 to keep the chassis 1 at a certain height from the ground, so that the dust on the ground will not affect the operation of the equipment, and at the same time it can To improve the stability of the equipment, a power chamber 2 is provided at the lower end of the chassis 1, and a coil 80 that can generate heat after being energized is provided in the power chamber 2, a power mechanism 20 is provided at the lower end of the power chamber 2, and two evenly distributed The upper end of the power chamber 2 is connected with a drying chamber 3. The inner wall of the drying chamber 3 is provided with a large number of uniformly distributed first holes 13 that allow impurities to pass through. The drying chamber 3 is provided with a device that can stir and beat cotton The striking mechanism 30, the striking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com