High-efficiency treatment device for grain airing

A processing device and high-efficiency technology, which is applied in the direction of dry goods processing, dry gas arrangement, and dispersed particle filtration, etc., can solve the problems of inability to dry grain and low efficiency of grain drying, so as to avoid external environment contact, high drying efficiency, and improve grain efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

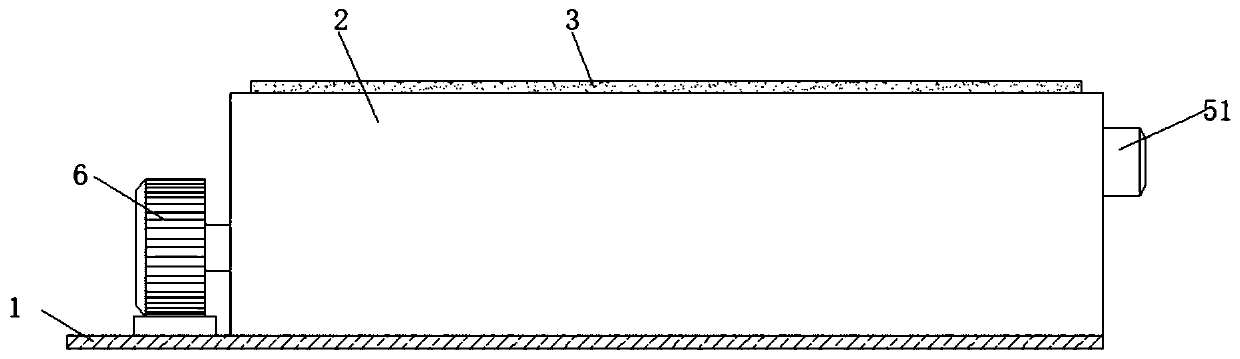

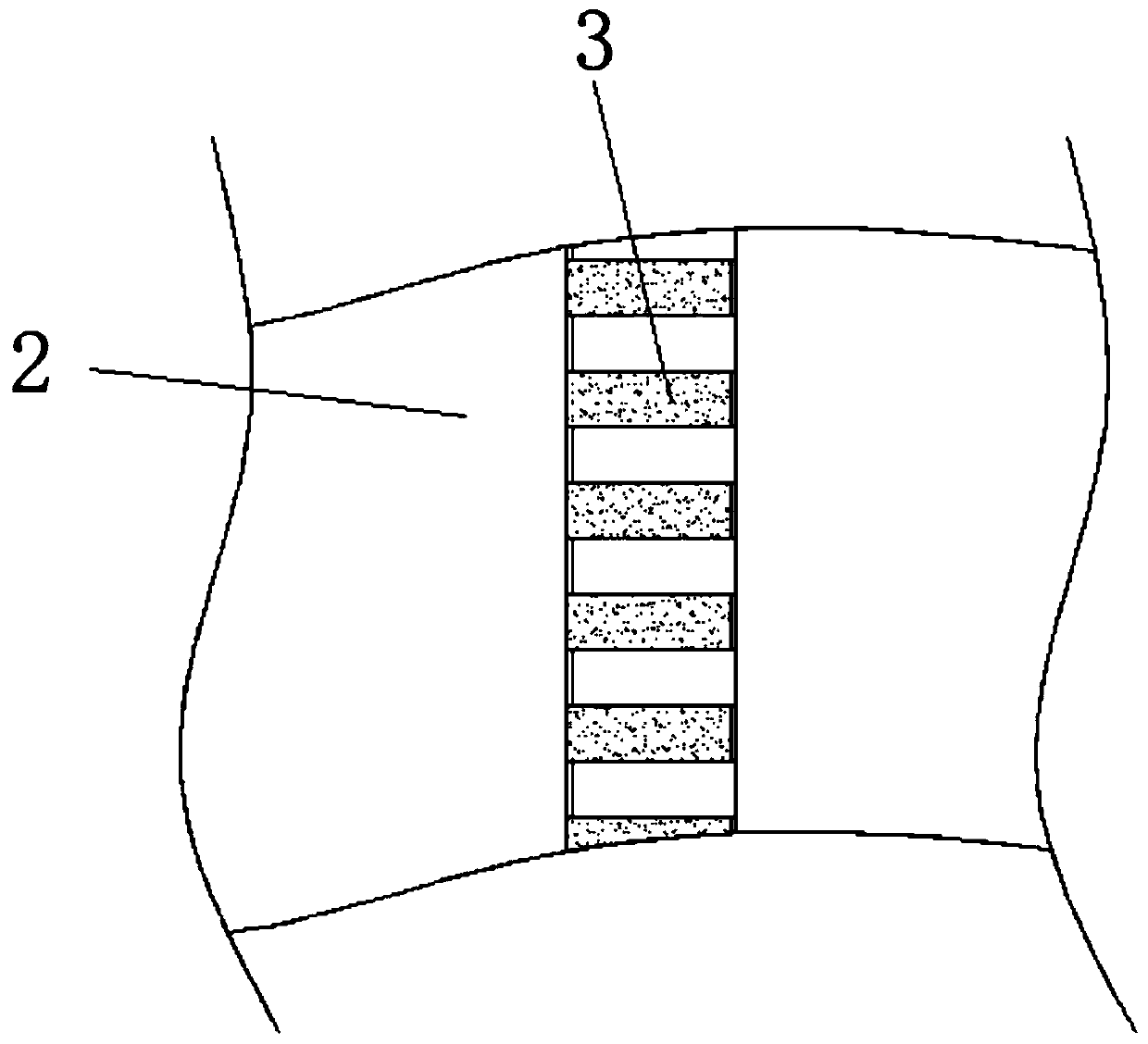

[0030] A high-efficiency processing device for grain drying, comprising a bottom plate 1, a plastic film 2 is fixedly installed on the upper surface of the bottom plate 1, and the two ends of the plastic film 2 are respectively connected with zippers 3, and the outer walls of the opposite sides of the plastic film 2 are symmetrical. Two semi-elliptical plastic films 4 are fixedly installed, wherein one end of the semi-elliptical plastic film 4 is fixedly installed on the upper surface of the base plate 1, and a blower 6 is fixedly installed, and the output end of the blower 6 is plugged and connected to the semi-elliptical plastic film 4 On the outer wall of the other semi-elliptical plastic film 4, a ventilation mechanism 5 is arranged on the side wall, and the inside of the plastic film 2 and the upper surface edge of the bottom plate 1 are fixedly installed with a mounting seat 7, and the mounting seat 7 is far away from the plastic film 2. One end side wall at the edge is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com