Gap Adjustment Method for Grate Running Chain

A gap adjustment method and chain grate technology, applied in the direction of combustion method, furnace, furnace type, etc., can solve the problems of increased gap between grate plate and chain link, so as to prevent material leakage, prevent running chain deviation, prevent Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

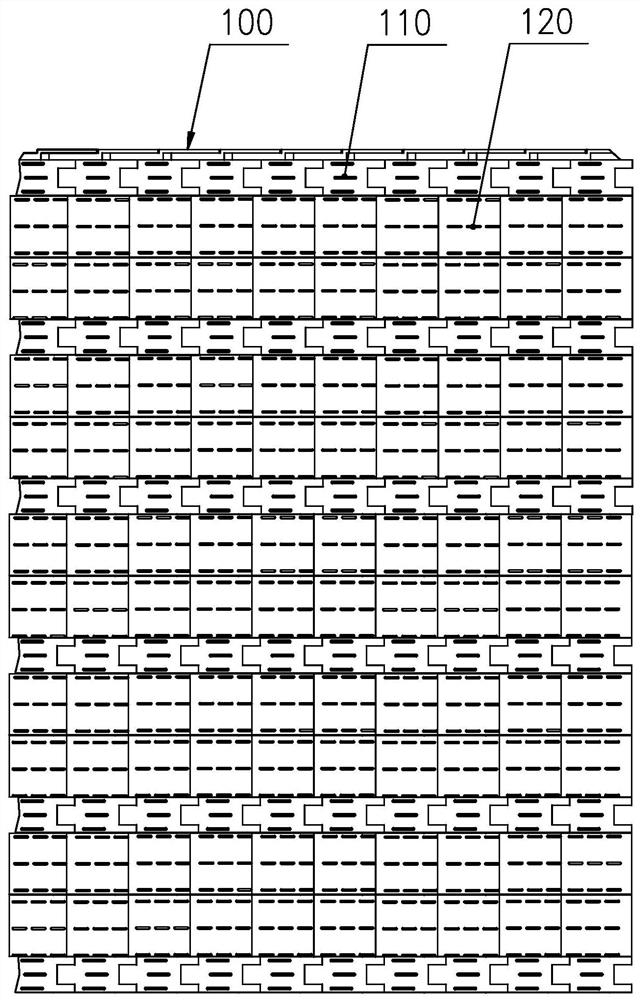

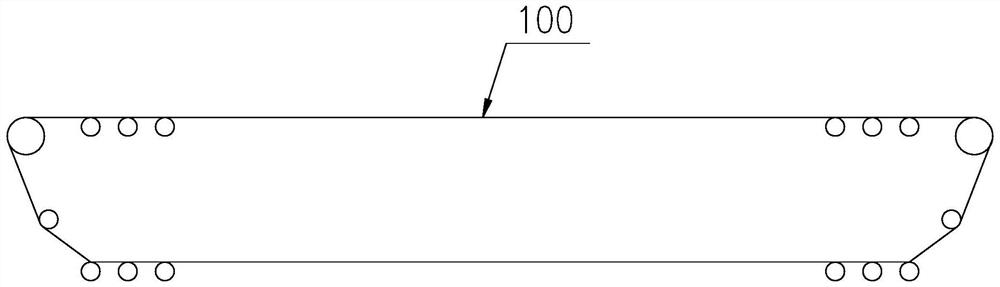

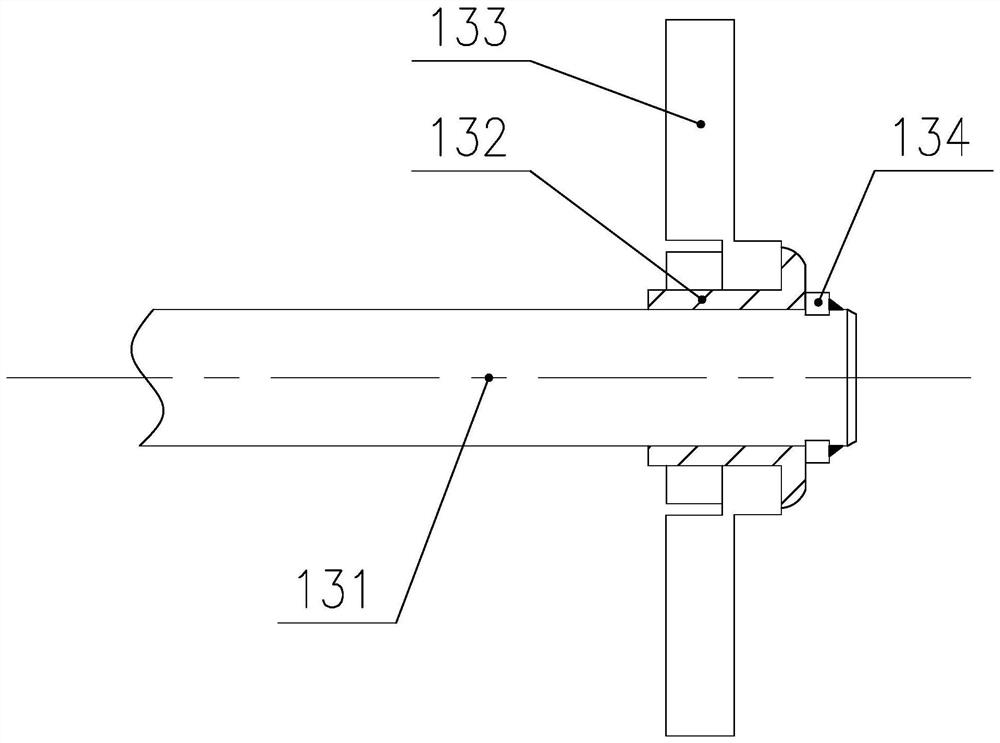

[0021] combine Figure 4 As shown, the gap adjustment method of the running chain of the grate machine, including the adjustment steps of the connecting components;

[0022] Steps for adjusting the connecting components: after the small shaft 131 has been in operation for 150-210 days, set the clip backing plate 135 between the small shaft sleeve 132 and the positioning card 134 .

[0023] This gap adjustment method offsets the extension of the small shaft 131 by setting the clip backing plate 135 between the small shaft sleeve 132 and the positioning card 134, thereby avoiding the gap between the grate plates 120 on the running chain 100 and between the grate plates 120 and the chain links 111. increase. By controlling the running time to 150-210 days, it can be ensured that the length dimension of the small shaft 131 tends to be fixed, and basically does not extend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com